TK-Global Engineering

TK Global Engineering - Presentation video

In order to ensure that our clients receive the best service possible, throught both our product range and our manufacturing facilities we have managed to entice and train one of the most qualified engineering teams available throughout the world today and with their help we are able to complete both our individual and industrial orders accordingly.

We also understand that stress, torque, fire, heat, material, tension, flexibility, nano-technology, textile and construction testing are all critical parts of Technokontrols engineering process and we therefore have provided our engineers with such facilities as a fully integrated 3D computer aided manufacturing (CAD /CAM) system along with many more testing technology aids (i.e. fire, heat, blast and metal stress testing technology) aids (i.e. fire, head, blast and metal stress testing technology) so as to ensure that our clients receive the best service available within the market today.

Blast testing technology

As per above, Technokontrol also manufactures all of its products to the highest possible international standards to which we are proud to state that we not only comply but in many cases we surpass the requirements needed in order to receive these international Quality certificates.

TK-Quality Assurance

A company-wide quality program, called the Technkontrol Quality System (TKQS), was developed specifically to meet the requirements of our business and our customers. A major ingredient of TKQS is that every employee is responsible for the end quality of our product.

In addition, the Quality Assurance Department is trained and knowledgeable of industry requirements and is capable of providing all documentation for initial sample review, production, and post-production support. They are solely committed to maintaining quality throughout the life of the product, and are experienced in problem prevention, analysis and solution techniques. The department is sufficiently staffed to insure total care, attention to detail and high quality levels.

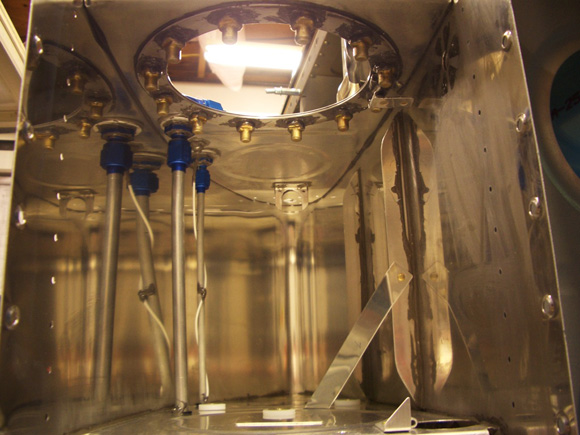

Technokontrol Laboratory Facilities

The analysis of raw materials before production is conducted here so as to be certain that it meets Technokontrols strict chemistry-alloys specifications, as well as metallurgical analysis of completed parts. We only purchase and develope exclusive & home patented alloys for each type of product and then prepare them for their future use. We have been able to develop and use all six of our TK-Generation alloys for distinct industries with our lat- est TK-VI Generation alloy being obviously the most advanced. Our V-V-VII Generation alloys have been developed especially for all gas related fuel based products whilst our new VII-VIII Generations Aerospace alloys are currently being developed and will be shortly available under the TK-Alloy Portfolio of Safety-Efficiency Technologies.

TK Alloy & Design Lab Testing

Here our product manufacturing processes are monitored and material manufacturing thicknesses, quality and design are verified. Every product has been designed for a specific industrial sector and our laboratories continuously test and verify that the correct type of materials are used. We strive to use superior exclusive and patented materials to surpass all quality and safety controls in all of our products and technologies in order to increase our product portfolio.

Our corrosion, durability & stress labs ensure that the final product meets and in some cases exceeds our customers specifications as well as Technkontrol’s own stringent requirements.

Other tests used by the Quality Department are hardness, tensile and proof-load, as well as non-destructive methods of testing. Our optical comparator is used for more accurate measuring and dimensional verification for critical situations where conventional methods are inappropriate or incapable. Electromagnetic, acoustic, heat and stress levels are performed at the highest international testing levels including sharing many of the unique testing technologies created at Technokontrol with Tech-Universities or third party research programs in technological joint-ventures.

Statistical Process Control (SPC) & On Sight Historical Quality Control (OHQC) is an important aspect of problem prediction and on going control before and after pro- duction. Areas such as alloy quality, piece hardness, mass, flexibility, weather, chemical corrosion, sabotage, accidental and dimensional control are monitored. Reproducibility and Repeatability (R&R) studies, and process /machine capability studies are also an integral part of the statistical quality assurance process.

Our manufacturing equipment and machinery is custom made exclusively for Technokontrol and is not available on the general market thus allowing us to create new technologies and to adapt swiftly to any new industry requirements.

This exclusive technology allows us to be independent and ensure that no other possible future competitor may appear on the market, thus allowing us long term product and technological exclusivity. General purpose automated multi-stations, packaging and other machinery complete our assortment our machinery portfolio. We offer vacuum, air-tight and atmospheric heat treatment, vacuum and atmospheric annealing, induction hardening and induction tempering. Fully-automated or semi-automated machines are used, depending on the volume requirements of our customer. Finishing equipment is specially designed for Technkontrol’s unique products.

Our tool room and grinding facility fully supports manufacturing as well as production of any necessary prototype hardware requirements we may have both now and in the future.

Technokontrol uses state-of-the-art technology and highly experienced personnel for the manufacturing of all of its products. Our complete in-house capabilities provide total control of the manufacturing process ensuring quality results. Our manufacturing system is de- signed for flexibility in choice of products without a loss of production efficiency. Computer-controlled cycle parameters maintain consistent quality control. A computer data base closely monitors part number, surface areas,volume,packaging and part weight to ensure uniform product quality and delivery.

TK Global Engineering Team

"Excellence is the unlimited ability to keep improving on the quality of what you have to offer".

Technokontrol has a large portfolio of products and services which depending on the product and its use in many occasions it can be directly purchased through our retail division ready for use as our TK-Anti Explosion Safety Fuel Cans and in many other applications can be simply applied as the TK-Anti Explosion Alloys for Home / DIY / Private / Motorsport use by following the incorporated instruction and safety manuals which do not require high levels of techni- cal backup for its use or application, even though we at Technokontrol are available for our clients needs to advise in the event of any possible issues with regards to our products use or application. “Safety is paramount and any question is better answered than a mistake occurring for not asking”.

On the other hand many other of our products and services due to their industrial and specialist application are complex and require high levels of technological knowledge with regards of the manufacturing and of their application and installation. We at Technkontrol believe that an essential part of the Technokontrol experience is the “Key in Hand” option and we strive to give our client’s the option of a 100% hassle free experience anywhere in the world.

If our client requires us to travel to supervise, verify and to apply any of our products or services from a motor yacht in the Caribbean, to a private plane in the USA or to a Speed boat in the UAE we will be available on hand at an obvious extra cost. Due to the availability of global communications the TK-Engineering Team can via confer- ence call, telephone or other possible means of communication offer advice minute by minute and even view if possible the correct installation or answer in-situ with any queries without travelling and without any additional expense to the client other than the purchase of the respective product.

TK-Global Engineering Team can also be part of any short, mid or even long term product safety program for which we will be on hand through any type of installation program before, during and even after the installation process for any government or corporate operation has been achieved, from an Auto GNV program to the complete installation within refineries, pipelines,jumbo tanks or petrol- chemical industrial units. Once the client has defined the installation program they require, we will both together decide whether or not to take a full TK-Global Engineering Team or to cre- ate a new National TK-Engineering Team on loca- tion of the respective installation program under a full time based TK-Global Engineer Monitor whom will prepare, train and supervise the clients staff or employees.

Normally, due to costs and due to installations programs being over several months or possibly years a based TK-Global Engineer Monitor is the best option due to reducing costs and also to preparing a National TK-Engineering team whom then can continue to use their knowledge, education and knowhow whitin other fields of application under new installation programs in the area or region for Technokontrol or their present or past employer.

In the case of Mid-Long term installation programs the TK-Global Enginering Team Director will prepare a full vocational-education program in which once passed the employee will obtain a certification to be allowed to install the Technokontrol technology upto those approved sectors/sections and this would also apply to all levels including management and directors levels.

Maintenance, Cleaning and Preparing for the Installation of TechnoKontrol

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Company Sections

- The Corporation

- Company Introduction

- Mission Statement

- Our Team

- Our Plant

- Product Presentation

- TK-Global Engineering

- TK-Global Electronics

- TK-Global Environment

- TK-Global Technotelecom

- TK-Corporate Governance

- TK-Emergency Call Center

Commitment to Quality

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering

More info

Should you want to receive more information, please contact us.