TK-MEABPMLFD Mobile Fuel Tanks

Technokontrol Military/Emergency Anti-Explosion Bullet-Proof Mobile Anti Fire/Heat Logistical Fuel Tanks

Technokontrol has designed a Military/Emergency Mobile Fuel Deposit which can be used in any military, civil or emergency zone. Our TK-Military/Emergency Anti explosion Mobile Fuel Tank can be deposited underground or hidden extremely easily, with the use of a bulldozer or using small construction diggers machinery / tractors a hole in the ground can be made to easily covered over and camouflaged with total secrecy for immediate of future use.

Our TK-Fuel M/E Mobile Fuel Tanks have side or top fuel access and pumping systems, manual and electric fuel chargers and pumping systems, anti-explosion fuel tanks , electric and manual distribution systems to be able to refuel and to discharge any military or emergency vehicles without the knowledge of the enemy/terrorist/sabotage elements but also totally protected in case of emergencies as forest fires or natural disasters.

The whereabouts and exact location will be always be in “classified hands” and with a GPS signal emitting system or manual mapping grading system this information will be passed on to any "Blue" forces where the exact secret location of the TK-Fuel tank is to refuel their vehicles at any time this also being an extremely well planned defensive logistical-tactical refuelling strategy.

These TK-M/E Mobile fuel tanks can be located/deposited in desert areas, jungles, cities and in the event of needing to advance or to regain lost ground in the event of war or social unrest the fuel logistics has already been established years ahead by these means.

These refuelling systems allows that environmental/emergencies government departments can have secure and safe refuelling logistical bases in all types of locations and thus being of extreme benefit in extremely hard and inaccessible areas as mountains, forests, extreme cold or hot locations with extreme humid environments where regular fuel delivery can be paramount for a military, emergency or even civilian life.

Benefits of the TK-Military / Logistical Anti-Explosion- Bullet Proof/ Heat/Fire Resistant Fuel Tank System:

- Technokontrol fuel tanks from 25,000-50,000 litres and annexing more units up to unlimited units.

- Technokontrol easy to transport on normal transport systems as they are contained inside the normal 40¨container size.

- Technokontrol electronic and manual pumping and control systems to be used even with no electric power for manual or emergency pumping.

- Technokontrol easy to re-use or to relocate as they are mobile as totally protected as the external container skin is anti-oxidation.

- Technokontrol anti-explosion protected fuel tanks.100% protected against explosion avoiding "BLEVE" ,"BOILOVERS" “SLOPOVERS” & “FROTHOVERS”

- Technokontrol safety extreme speed-safety refuelling valve system to reduce unloading or refuelling times by 40% to reduce static physical refuelling time exposure at refuelling stages.

- Technokontrol “anti-slosh” fuel tanks for secure mobility and transport even when filled with fuel to final deposit location saving time after installation and thus not needing immediate refuelling.

- Technokontrol external protection skin made of anti-oxidation materials to stop long term corrosion especially for underground fuel tanks.(Stainless Steel.)

- Technokontrol external fuel tank container skin protected with bullet proof Level III protection panels against indirect/direct light armament attacks as bullets or shrapnel hits.

- Technokontrol external Heat/Fire protection panels of up to 1600º for three hours or more to avoid container and fuel tank damage.

- Technokontrol electronic GPS location device for electronic tracking systems for relocating at transport mode or for finding in covert operations.

- Low electronic emissions for higher security and harder enemy or un-authorized locating and to protect against theft of fuel.

- Side or both top level refuelling pumping systems for complete underground secrecy and security.

- Alarm systems incorporated and if under electric power surveillance cameras can be located for 24/7/365 days visual and audio protections with direct relay of data to bases.

- Low maintenance servicing programme and easy cleaning.

- Long life as all manufacturing materials are used are for long term logistical operations and even protected against internal fuel algae growth or oxidation damage.

- Storage can be of any type of fuels and chemicals from normal gasoline to military or aviation fuel for helicopters, aircraft and especially for fire fighting aeroplanes-transport to reduce flying times between fires or long distance patrols.

TK-Military/emergency Anti Explosion Mobile Fuel Tank

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS®

Building Concept

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUELTANKS® - SECURITY & SAFETY CONCEPT

Leak detecting device on the tank

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS® - Building Concept

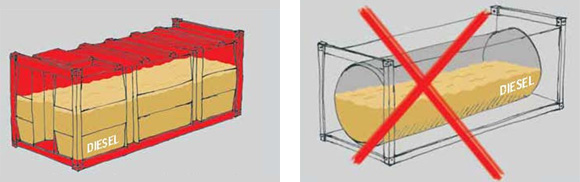

Traditional gas-station containers are built of normal freight containers, in which a standard tank and the required equipment are placed at great expense. This method of construction gives away a lot of space, and it is instable due to not having our "TK-Anti-slosh-fuel protection system which would help and increase higher transportability but even with our anti-slosh technology the waste of volume is too important to compensate its design.

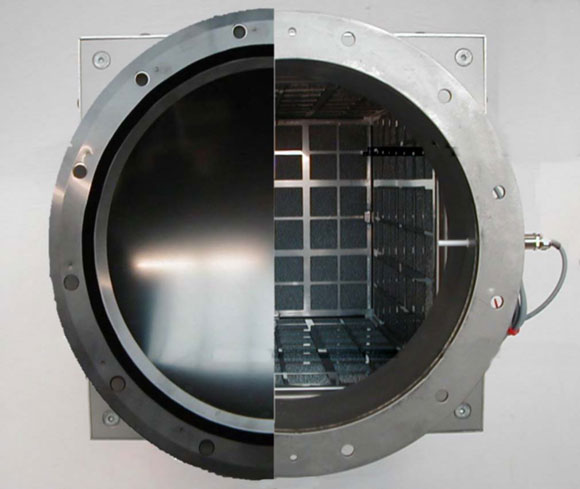

TK-Fuel tank storage with treble wall protection against Fire / Heat, Bullet proof and anti-oxidation/algae growth.

Representation of Space Division

| Type of tank No. of item |

Volume litre |

Length mm |

Width mm |

Height mm |

Height of tank mm |

Dead weight kg (approx.) |

|---|---|---|---|---|---|---|

| TK-AX-MFT 10ft. | 10.000 | 2.991 | 2.438 | 2.438 | 2.000 | 2.400 |

| TK-AX-MFT 20ft. | 24.000 | 6.058 | 2.438 | 2.438 | 2.000 | 5.600 |

| TK-AX-MFT 40ft. | 50.000 | 12.192 | 2.438 | 2.438 | 2.000 | 10.000 |

Standard equipment:

- Load-carrying-system construction, consisting of stable frame structure with 8 pieces

- Robust, cubic, treble wall body of steel.

- Double fuel entry refueling, systems-roof & side

- Electric & manual pumping systems

- Operational with electric motor or totally manually

- GPS locator and Tracking devices.

- TK-Anti explosion fuel tank

- TK-Anti-Slosh fuel tank

- TK-Anti-oxidation & anti-algae protection

- Treble wall protection system made of steel and anti-oxidation.

- Bullet proof wall panels protecting container Level III Protection.

- Anti-fire/heat protection panels for over 1000ºC direct fire blast for over 3 hours total protection.

- Easy transport with connectors for helicopter air transport.

- Usable for all types of fuels and chemicals

- Manhole & ladder incorporated

- Built for long term underground use or storage

- Thermal protection

- Tank roof is self-supporting single wall construction.

- The hatch compartment is mounted on the tank roof, installed with:

- a sealing hood with a gas pressure spring, a handle strip and a padlock

- a man hole DN 500

- access interfaces (bush 2“)

- vent connections DN 50, a vent hood 2“ IG

- a mechanical level indicator (fuel dip stick)

- emptying of residues

- Function niche, front side, including a sealing door, width 800 mm, depth: 500 mm, height: 2.000 mm

- Leak warning device

- Electrical connection

Corrosion protection:

- Inside : rough, oiled

- Outside: 2-K coating-color coded at clients request or stainless steel/anti-oxidation metal.

- Separating walls for more-chamber tank

- Overfilling protection

- Level sensor

- Equipment function niche, front side

- Filling system for tank cars

- Withdraw system

TK-M/E FUEL TANK CONTAINER TREBLE WALL

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS®

Storage container view: 20ft. Storage container with integrated ladder and hatch compartment

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS®

Equipment of storage view: hatch compartment with dome cover, connecting sleeves, limiting level transmitter, vent, fuel dip stick

FUEL TANKS®

Equipment of fuel tanker storage container View: leak detecting device installed in the section/department

FUEL TANKS®

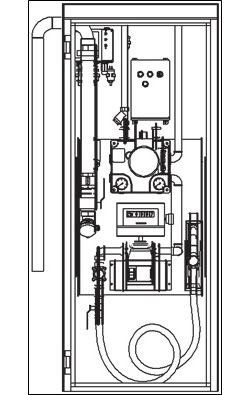

View: transfer pump up to 1000 litre/min for self-filling of the tank in the closable section/ department

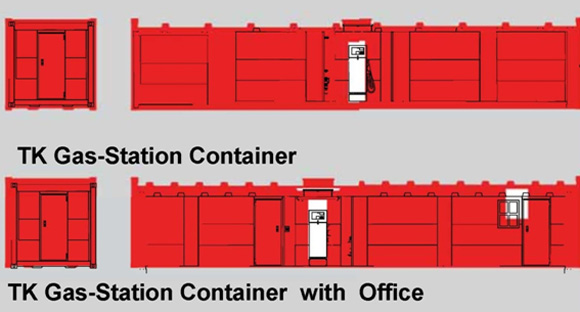

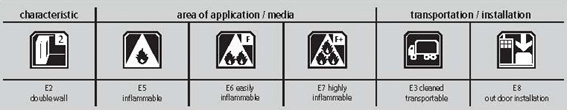

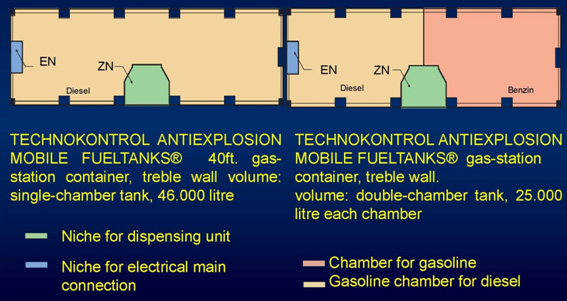

GAS-STATION CONTAINER TREBLE WALL PROTECTION

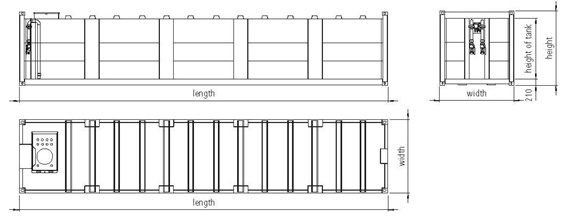

Technical Data

| Type of tank No. of item |

Volume litre |

Length mm |

Width mm |

Height mm |

Height of tank mm |

Dead weight kg (approx.) |

|---|---|---|---|---|---|---|

| TK-AX-MFT 10ft. | 10.000 | 2.991 | 2.438 | 2.438 | 2.000 | 2.400 |

| TK-AX-MFT 20ft. | 24.000 | 6.058 | 2.438 | 2.438 | 2.000 | 5.600 |

| TK-AX-MFT 40ft. | 50.000 | 12.192 | 2.438 | 2.438 | 2.000 | 10.000 |

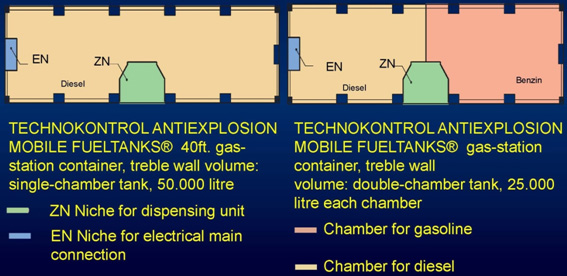

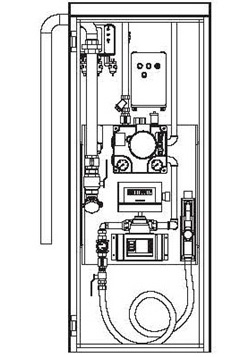

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS® 40ft.

View: Dispensing gas pump; standard equipment for diesel; electrical, lockable, integrated in the front side of the container

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS® 40ft.

View: dispensing gas pump

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS® 40ft.

View: standard equipment for diesel

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUELTANKS® 40ft.

View: electrical niche with distributor

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUELTANKS® 40ft.

View: filing pipe, installed in dispensing and fire emergency equipment.

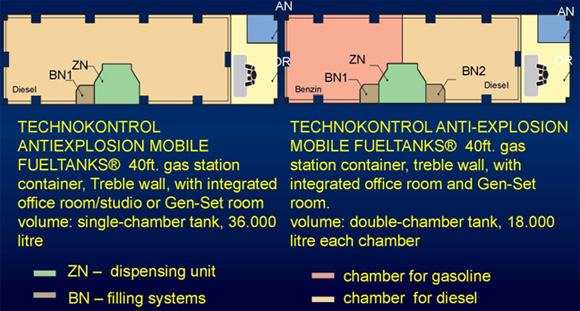

TK-E/M ANTI EXPLOSION MOBILE FUEL TANK TREBLE WALL PROTECTION/STUDIO

Representation of Space Division

Technical Data

| Type of tank No. of item |

Volume litre |

Length mm |

Width mm |

Height mm |

Height of tank mm |

Dead weight kg (approx.) |

|---|---|---|---|---|---|---|

| TK-AX-MOF 20ft. | 16.000 | 6.058 | 2.438 | 2.438 | 2.000 | 6.800 |

| TK-AX-MOF 40ft. | 36.000 | 12.192 | 2.438 | 2.438 | 2.000 | 11.200 |

Standard equipment:

- Load-carrying-system construction, consisting of stable frame structure.

- Robust, cubic, treble wall body of steel.

- Double fuel entry refueling systems-roof & side.

- Electric & manual pumping systems.

- Operational with electric motor or totally manually.

- GPS locator and Tracking devices.

- TK-Anti-explosion fuel tank.

- TK-Anti-Slosh fuel tank

- TK-Anti oxidation & anti-algae protection

- Treble wall protection system made of steel with anti-oxidation protection

- Bullet proof wall panels protecting container

- Anti-fire/heat protection panels for over 1000ºC direct fire blast for over 3 hours total protection.

- Easy transport with connectors for helicopter air transport.

- Usable for all types of fuels and chemicals

- Manhole & ladder incorporated

- Built for long term underground use or storage

- Thermal protection

- Tank roof is self-supporting single wall construction.

- The hatch compartment is mounted on the tank roof, installed with:

- Sealing hood with a gas pressure spring, a handle strip and a padlock

- Man hole DN 500

- Access interfaces (bush 2“)

- Vent connections DN 50, a vent hood 2“ IG

- Mechanical level indicator (fuel dip stick)

- Emptying of residues

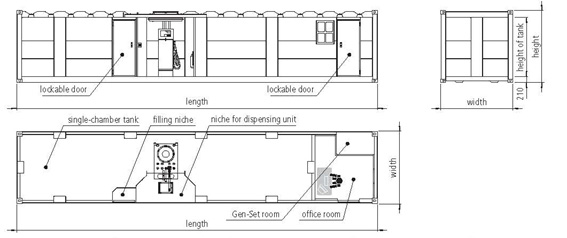

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS® 40ft.

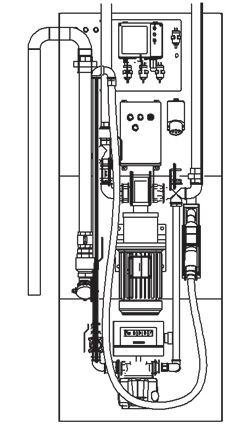

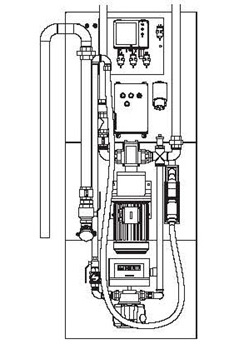

Gas-station container view: dispensing niche with gas pump for diesel; filing section for transfer pump; office with power set and air conditioning and heating.

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS® 40ft.

View: standard equipment for diesel, transfer pump for self-filling.

TECHNOKONTROL M/E FUEL TANK DISPENSING UNITS, GAS PUMPS, UNATTENDED GAS PUMPS

Technical Data of Fuel Container Dispensing Units

Delivery rate 40 litre/min

Calibratable

Medium: vegetable oil

4 - piston meter with mechanical counting device electrical connection pump 3 x 230/400 V AC, 50 Hz

1 dispensing point

Dispensing tube: 4 m DN 25, with design approved automatic dispensing valve, dispensing tube holder

Delivery rate 100 litre/min

Calibratable

Medium: vegetable oil

4 - piston meter with mechanical counting device electrical connection pump 3 x 230/400 V AC, 50 Hz

1 dispensing point

Dispensing tube: 4 m DN 25, with design approved automatic dispensing valve, dispensing tube holder

Delivery rate 40 litre/min

Uncalibratable

Medium: diesel, biodiesel, vegetable oil

Electrical connection 3 x 230/400 V AC, 50 Hz

1 dispensing point

Dispensing tube: 4 m DN 25, with design approved automatic dispensing valve, dispensing tube holder

Delivery rate 100 litre/min

Uncalibratable

Medium: diesel, biodiesel, vegetable oil

Electrical connection 3 x 230/400 V AC, 50 Hz

1 dispensing point

dispensing tube: 4 m DN 25, with design

approved automatic dispensing valve, dispensing tube holder

One – Medium Gas Pump

applicable media: diesel, biodiesel, vegetable oil, gasoline, kerosene, bioethanol, abblue

design: calibratable/ uncalibratable

1x pump compact block with degassing device and strainer

delivery rate max. 80 litre/min

electrical connection 3 x 230/400 V AC, 50Hz

designed for temperatures from -20 to +50 °C

1x counting device: 4- piston meter

1x dispensing tube: 4 m DN 25, with design approved automatic dispensing valve, dispensing tube holder

Two – Media Gas Pump

applicable media: diesel, biodiesel, vegetable oil, gasoline, kerosene, bioethanol, abblue

design: calibratable/ un calibratable

2x pump compact blocks with degassing devices and strainers

delivery rate max. 80 litre/min

electrical connection 3 x 230/400 V AC, 50Hz

designed for temperatures from -20 to +50 °C

2x counting device: 4- piston meter

2x dispensing tube: 4 m DN 25, with design approved automatic dispensing valve, dispensing tube holder

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS®

Gas-Station Container, Dispensing Unit (calibratable/ uncalibratable) for dispense volume of 50 – 150 litre/min

View: dispensing unit for 2 media (diesel, biodiesel or gasoline)

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUELTANKS®

Dispensing Unit (calibratable) for dispense volume of 50 – 120 litre/min

View: dispensing unit for 1 medium (diesel, biodiesel or gasoline) and transfer pump for self-filling of the tank up to 1000 litre/min in lockable niche

TECHNOKONTROL ANT-IEXPLOSION MOBILE FUELTANKS®

Gas-Station Container Generator 6 kVA for Self Supply in Continuous Operation - Sound Insulated

View: generator – easy fuelling by pulling it out to service/ fuelling position

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUELTANKS®

Gas-Station Container, Dispensing Unit (calibratable) for dispense volume of 50 – 120 litre/min

view: dispensing unit for 2 media (diesel, biodiesel or gasoline)

TECHNOKONTROL ANTIEXPLOSION MOBILE FUELTANKS® 40ft.

Storage-Tank-Container Combination in Use as Fuel Tank Farm. Enables on the one hand a quick, uncomplicated transport by ship, rail and road. On the other hand, they grant the easy assembling, dismantling and rebuilding of the battery tank farms, for example at time-limited locations

TECHNOKONTROL ANTIEXPLOSION MOBILE FUELTANKS® 40ft.

Storage-Tank-Container Combination in Use as FUEL Tank Farm. The storage tank containers can be connected with each other without any difficulty. It enables building up of battery tank farms, like for example those needed for distribution of mineral oil.

TECHNOKONTROL ANTIEXPLOSION MOBILE FUELTANKS® 20ft.

Storage Tank Container and Functional Container for Heat and Power. The combination of a storage tank container and a functional container with an integrated Gen-Set serve to generate heat and power for the attached building. The storage tank supplies the Gen- Set functional container with the necessary liquid fuel

TECHNOKONTROL ANTIEXPLOSION MOBILE FUELTANKS® 20ft.

The combination of a storage tank container and a functional container with an integrated CHP serve to generate heat for the attached building. The storage tank supplies in this case the CHP in the functional container with the necessary liquid fuel.

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS® 20ft.

Storage-Tank-Fuel for Supplying a Gen-Set container farm with fuel and engine oil as well as the intermediate storage of incidental old oil.

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS® 40ft.

Transport, delivery and underground protection.

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS® 40ft

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS® 40ft.

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUELTANKS® 40ft.

TECHNOKONTROL ANTIEXPLOSION MOBILE FUELTANKS® 40ft.

Fuel tank station in use as gas station for freight companies on work yard with integrated office room.

TECHNOKONTROL ANTIEXPLOSION MOBILE FUELTANKS® 20ft.

Gas-station in use as a self-sustaining gas station. The high safety standard of the treble wall ensures riskless supply to vehicles with fuels in sensible ecosystem.

TECHNOKONTROL ANTIEXPLOSION MOBILE FUELTANKS® 40ft.

Gas-Station Fuel tank in use as a self-sustaining gas station. The gas-station container ensures supplying to vehicles with fuels. Its equipment enables the trouble-free operation at tempera- tures from -25° C to + 55°C

TECHNOKONTROL ANTIEXPLOSION MOBILE FUELTANKS® 20ft.

Gas-Station Fuel in use on site of road works. The building site locates in an area without infrastructure. All construction vehicles can get fuelled directly on the construction site which is hard to access safely and comfortably. After completion of the work, the gas-station container will be placed on the next construction site.

TECHNOKONTROL ANTIEXPLOSION MOBILE FUELTANKS® 20ft.

Gas-Station Fuel tank in use on site of road works. The building site locates in an area without infrastructure. All construction vehicles can get fuelled directly on the construction site which is hard to access safely and comfortably. After completion of the work, the gas-station container will be placed on the next construction site.

TECHNOKONTROL ANTIEXPLOSION MOBILE FUELTANKS® 20ft.

Gas-station in use as gas station for boats. The gas-station container fastened at pontoon ensures supplying to boats and ships with fuels at all time. The changes of water levels will be balanced due to the fastening of the pontoon at a mast anchored in waters without any problems.

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUEL TANKS® 10ft

Views: gas-station container with dispensing niche in the long side and electrical niche integrated in the front side/ dispensing unit (uncalibratable) of dispense volume 80 litre/min

TECHNOKONTROL ANTIEXPLOSION MOBILE FUELTANKS® 20ft.

Gas-station container view: dispensing niche integrated in the front site/ dispensing unit 150 litre/min (calibratable)

TECHNOKONTROL ANTI-EXPLOSION MOBILE FUELTANKS® 40ft.

Gas-station container View: dispensing niche integrated in the front site/ transfer pump, dispensing unit 50 litre / min (calibratable)

Video Presentations

- TechnoKontrol Safety Videos

- What is B.L.E.E.V.E.? Explanation

- Fuel explosion examples

- Fuel Barrel Flame Ignition & Welding Test - Prueba de Ignición y Soldadura en un Barril de Combustible

- Pipeline Explosion Test - Prueba Anti-Explosión en Ductos

- Security Test (SPA) - Prueba de Seguridad

- Heat Conductivity of TK Alloys - Conductividad térmica de malla TK

- Fuel Vaporization Test - Prueba de vaporización de combustible

- Types of TK Alloy Formats - Formatos de presentación de malla TK

- Alloy Vaporization Test

ATEX - European Antiexplosive Safety Directives

PREPARATION/DEGASIFICATION OF A PETROL STATION FUEL TANK, FUEL TANKERS, STORAGE FACILITIES BEFORE ATEX/NFPA: TK-ANTI-EXPLOSION ALLOYS INSTALLATION

ATEX/NFPA SAFETY DIRECTIVES FOR ATMOSPHERIC GAS/PETROL-CHEMICAL RISK-EXPLOSION ZONES

ATEX/NFPA EXTREME DANGER-DISCHARGING OF EXPLOSIVE GASES/VAPOURS AT PETROL STATIONS, MANHOLES, STORAGE TANKS

IMAGE OF AN ATEX/NFPA PETROL STATION MANHOLE REFUELING POINT WITHOUT TECHNOKONTROL ANTI-EXPLOSION ALLOYS

ATEX/NFPA ANTI-EXPLOSION/SAFETY DISCHARGING-REFUELING VALVES FOR PETROL STATIONS, FUEL DEPOTS, REFINERIES, PETRO-CHEMICAL PLANTS

ATEX/NFPA ANTI EXPLOSION, ANTI-ELECTROSTATIC, ANTI-SLOSHING, ANTI-VAPOR SAFETY VALVES "CUSTOM MADE" FOR EACH CLIENT AND TECHNICAL-INSTALLATION REQUIREMENTS

ATEX-/NFPA PETROL STATIONS-MAN HOLES, STORAGE FACILITIES, REFUELING AREAS - ATEX-EU/NFPA EXPLOSIVE ATMOSPHERIC DIRECTIVE DANGER SECTIONS

ATEX-NFPA TECHNOKONTROL ANTI-EXPLOSION-SPECIALIST SAFETY TECHNOLOGIES

SPECIALIST UNIQUE PATENTED ALLOY FORMULATIONS & DESIGNS FOR ALL ENGINEERING-TECHNICAL REQUIREMENTS INCLUDING USAGE FROM PROTECTION-SAFETY TECHNOLOGIES TO PETROL-CHEMICAL-ENVIRONMENTAL INDUSTRIES

TECHNOKONTROL SPECIALIS ANTI-VAPORIZATION, ANTI-THERMAL & ANTI-ELECTROSTATIC CHARGES ALLOYS FORMULATIONS

ANTI-EMPS (ELECTROMAGNETIC PULSES/RADIATION), SPACE/SATELLITE/AVIATION EXTREME THERMAL HEAT ATMOSPHERIC RE-ENTRY ALLOYS, ETC.

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Petro-Chemical / Gas Tanks Protection

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects