Oil Tankers, Barges, Ports, Vessels Protection, Safety, Security & Efficiency Technologies

TK Maritime - Sea/River/Lake/Safety, Efficiency & Security Technologies

Technokontrol Maritime Safety Technologies can provide its clients the best possible and of the highest safety, security, efficiency standards to prevent these operational, long terms assets in being protected as much as possible in the event of being attacked, sabotaged, suffering of accidents or operational incidents during maintenance, transport, refueling, loading, unloading, port deliveries, bunkering, etc.

TK-Maritime offer its clients the possibility to use several of its unique, patented, guaranteed safety, security, efficiency technologies for the use of any petro-chemical transports especially by maritime transportation methods.

Technokontrol can offer these following benefits which are being used already by government navy and safety maritime departments around the World:

- No explosions due to gas, fuels leaks due to external-internal accidental damage.

- No corrosion or oxidation inside the double hull, exterior or internally inside the vessels fuel tanks.

- No oxidation in the full fuel tank deposits due to Technokontrol anti-corrosion technologies.

- No algae growth inside fuel deposits protecting fuel quality and fuel chemical standards.

- All NEW/NON OPERATIONAL fuel tankers, vessels, barges will benefit from 100% anti-corrosion, anti algae growth from the very start before operation once the alloys have been installed at the shipyard.

- All USED/OPERATIONAL fuel tankers , vessels, barges will benefit that their present oxidation, corrosion, algae growth issues, complications will be” HALTED/STOPPED” with immediate effect once our Technokontrol Alloys are installed but the already present corrosion and/or algae growth will not be returned to new standards but will be “halted” to again extend the operational life of the vessels and thus its financial amortization.

- No petro-chemical properties or chemical compositions changes will occur due to being in contact with Technokontrol alloys at any stage.

- Reduction of fuel vaporization if fully installed of up to 98% of the fuel transported or delivered.

- Reduction of aprox 5%-12% due to fuel fumes, vapors vaporization if only used between storage facilities, road tankers, petrol station, final end user, the client.

- No electro static charges can ignite the protected fuel tanks from climatic electrostatic charges or due to human operational reason as static for un-loading/loading fuel tanks at high speeds or similar reasons.

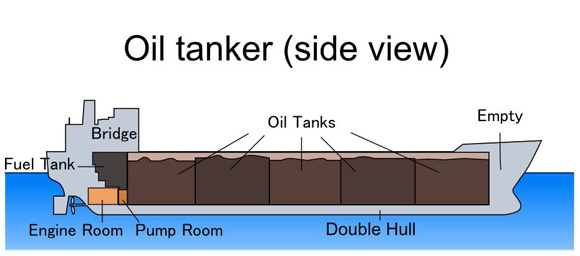

- Reduction in "sloshing movement" especially at high/strong seas where the vessels will not suffer from "sloshing" especially when not fully loaded or even empty when the ship to mostly more prone to have ballast or fuel movements.

- The use and operation of using Technokontrol "Safety Anti-Explosion Valves" and even the unique, patented advanced "High Speed Valve ", which can increase loading/unloading of fuels, petrol-chemicals depending of each type of fuel from 25% to 52% faster and with no risk of explosion fire, or ignition.

- The reduction of "sloshing movement" is also beneficial due to reducing metal stress at all external and internal vessel design levels also extending the vessels operation live span due to this and the reduction of corrosion which sea vessels suffer greatly.

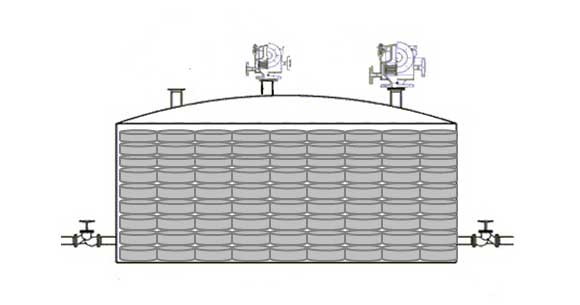

- Technokontrol Alloys only occupies 1% in MESH format of the fuel tanker capacity thus a 100 ton fuel tanker will only lose 1 ton of fuel capacity per 100 tons. Thus 99 tons fuel net capacity is still remaining for the operator to be used.

- Technokotrol weighs only 0,25-0,50 grams per liter of fuel capacity thus 1000 liters or 1m3 of fuel the alloy installed only weighs from 25- 50 kilos installed due to its extreme light weight properties. The weigh difference is depending in the alloy required due to the vessels usages, age, climatic routes, production transport thus being of" lighter or heavier" alloy weight for each type of vessel and of use.

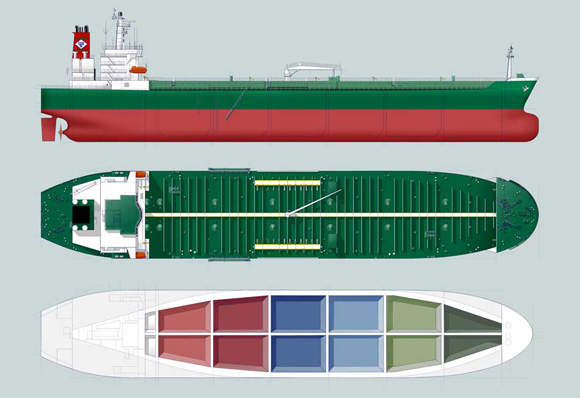

OIL, PETROL-CHEMICAL SEA TANKERS, PORTS & REFUELING BARGES TECHNICAL DESIGNS & EXPLOSION INCIDENTS BY SABOTAGE, PIRACY TERRRORISM OR ACCIDENTS EXPLANTIONS, IMAGES, DEMOSTRATIONS.

IMAGES OF SEA FUEL TRANSPORT VESSELS, PORTS, FUEL BARGES,BUNKERING VESSELS ATTACKED BY TERRORISTS, SABOTAGE, PIRACY OR OPERATIONAL INCIDENTS/ERRORS FROM AROUND THE WORLD.

FUEL BARGE BUNKERING FIRE & EXPLOSIONS

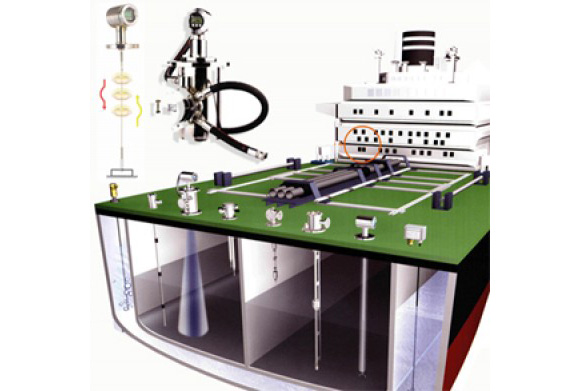

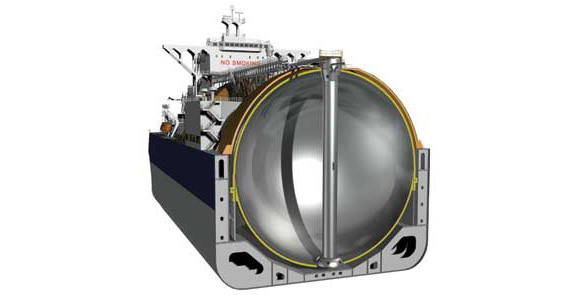

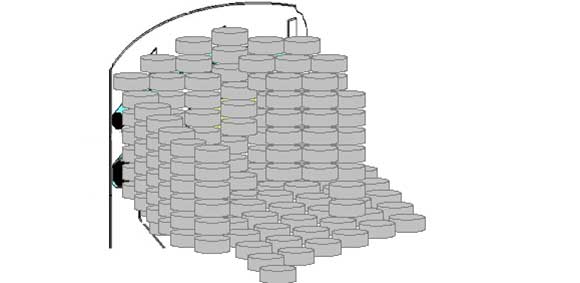

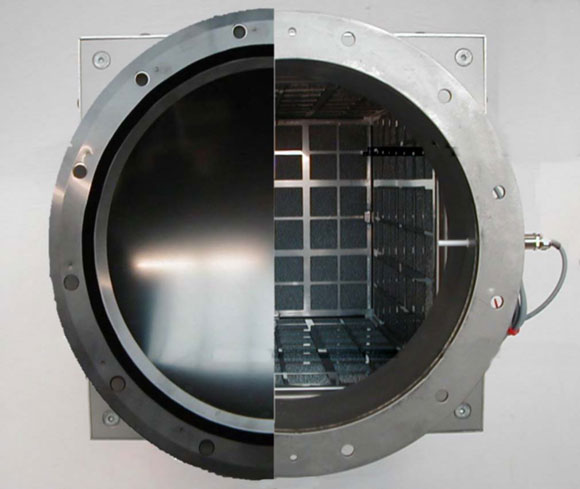

Fuel tank internal installation process images depending on size, volume, petro-chemical stored

Larger Fuel/Jumbo tanks will require specialist infrastructure systems designed and installed by TK-Global Engineering to install fully the internal volume of the tanks with our anti-explosion, anti-vaporization, anti-corrosion, anti-algae, anti-electrostatic safety and security technologies.

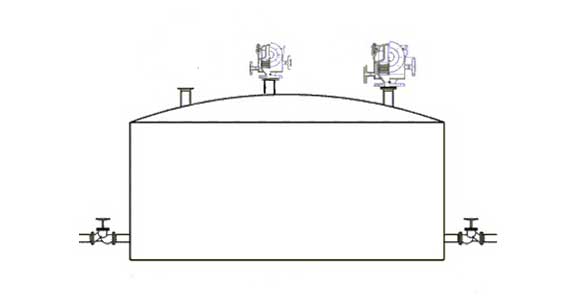

Empty tank - Tank without protection

TK Alloy being installed into tank

Full tank - Tank completely protected with TK Alloy

Chemical accidents, sabotage & terrorist actions against strategic national industrial, commercial, economic and transport systems.

An Anti-chemical fire fighting/chemical protection machine is seen at the site of a chemical freight train explosion trying to dispurse atmospheric chemicals which may reach the general population or even injure, kill, fire fighters, civil protection , health & safety operators, investigators, law enforcemnet operatives an and ground-aerial emergency services, etc.

These safety & security anti-chemical contamination systems can be used, transported, installed in all types of our Technokontrol vessels, transports, safety platforms involving petro-chemical plants, storage facilities, refineries, chemical production plants, pipelines, rail freight, ports, harbors, etc.

Chemical transports can not only be used for normal industrial & commercial use but also used for an easy, effective way for sabotage, terrorist, anti-system attacks in any nation at global level as chemicals accidents or incidents can be easily made into chemical explosives7explosions with the simple derailment of a train, road tanker, saboatge of port chemical refueling/discharge facilities, internal plant fires, emergency operational system closures, etc.

Worst of all of atmospheric chemical sabotage, terrorist attacks which can be covered as operational accidents but really have political, strategic social, media and economic intentions to effective whole transport networks and closing, evacuating town, cities, general population.

These accidents have already occured three times in the last year in Belgium where we all believe that safety and security are always of the highest european levels but as one can see these accidents or attacks can happen to any nation, operator, anywhere and at anytime globally, thus prevention, security and safety using Technokontrol technologies is and always will be paramount at all levels, especially at government, transport,law enforcement,civil protection, health & safety levels for any nation regardless of its global location.

Video Presentations

- TechnoKontrol Safety Videos

- What is B.L.E.E.V.E.? Explanation

- Fuel explosion examples

- Fuel Barrel Flame Ignition & Welding Test - Prueba de Ignición y Soldadura en un Barril de Combustible

- Pipeline Explosion Test - Prueba Anti-Explosión en Ductos

- Security Test (SPA) - Prueba de Seguridad

- Heat Conductivity of TK Alloys - Conductividad térmica de malla TK

- Fuel Vaporization Test - Prueba de vaporización de combustible

- Types of TK Alloy Formats - Formatos de presentación de malla TK

- Alloy Vaporization Test

Documentation

ATEX - European Antiexplosive Safety Directives

PREPARATION/DEGASIFICATION OF A PETROL STATION FUEL TANK, FUEL TANKERS, STORAGE FACILITIES BEFORE ATEX/NFPA: TK-ANTI-EXPLOSION ALLOYS INSTALLATION

ATEX/NFPA SAFETY DIRECTIVES FOR ATMOSPHERIC GAS/PETROL-CHEMICAL RISK-EXPLOSION ZONES

ATEX/NFPA EXTREME DANGER-DISCHARGING OF EXPLOSIVE GASES/VAPOURS AT PETROL STATIONS, MANHOLES, STORAGE TANKS

IMAGE OF AN ATEX/NFPA PETROL STATION MANHOLE REFUELING POINT WITHOUT TECHNOKONTROL ANTI-EXPLOSION ALLOYS

ATEX/NFPA ANTI-EXPLOSION/SAFETY DISCHARGING-REFUELING VALVES FOR PETROL STATIONS, FUEL DEPOTS, REFINERIES, PETRO-CHEMICAL PLANTS

ATEX/NFPA ANTI EXPLOSION, ANTI-ELECTROSTATIC, ANTI-SLOSHING, ANTI-VAPOR SAFETY VALVES "CUSTOM MADE" FOR EACH CLIENT AND TECHNICAL-INSTALLATION REQUIREMENTS

ATEX-/NFPA PETROL STATIONS-MAN HOLES, STORAGE FACILITIES, REFUELING AREAS - ATEX-EU/NFPA EXPLOSIVE ATMOSPHERIC DIRECTIVE DANGER SECTIONS

ATEX-NFPA TECHNOKONTROL ANTI-EXPLOSION-SPECIALIST SAFETY TECHNOLOGIES

SPECIALIST UNIQUE PATENTED ALLOY FORMULATIONS & DESIGNS FOR ALL ENGINEERING-TECHNICAL REQUIREMENTS INCLUDING USAGE FROM PROTECTION-SAFETY TECHNOLOGIES TO PETROL-CHEMICAL-ENVIRONMENTAL INDUSTRIES

TECHNOKONTROL SPECIALIS ANTI-VAPORIZATION, ANTI-THERMAL & ANTI-ELECTROSTATIC CHARGES ALLOYS FORMULATIONS

ANTI-EMPS (ELECTROMAGNETIC PULSES/RADIATION), SPACE/SATELLITE/AVIATION EXTREME THERMAL HEAT ATMOSPHERIC RE-ENTRY ALLOYS, ETC.

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Maritime, River, Port Protection

Petro-Chemical / Gas Tanks Protection

TK Military Maritime

Platform Video Explosions & Reports

- BP Gulf Mexico Platform Explosion

- Elgin Gas Leak Video Explanation

- BP Gulf Explosion Full Video Explanation

- BP Gulf Video Corporate Video Explanation

- Gulf of Mexico Platform Explosion

- Live Platform Explosions

- Live Platform Damage Images

- Louisiana Sea Platform Explosion

- How to Prevent Deep Sea Platform Explosions

- Photo-Video of Deep Sea Platform Unique Photos

- North Sea Platform Shut Down due To H&S Explosion Risks

Types of LNG/FLPG Video Explanations

- Floating FLPG/Natural Gas Floating Vessel Platforms

- LNG Super Tanker Video

- LNG Video Summary

- First FLPG Shell Platform Vessel

- Multipurpose LNG Terminal Vessel Operations

- LNG Production Video Explanation

- LNG FPSO Vessel Contractors

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Ships Collissions

- Luxury Yacht catches Fire

- Explosion on a tanker ship

- MISC ship explosion at Petronas methanol Labuan

- MT Prem Dyvia explosion

- Destroyed in seconds-oil tanker explosion

- Oil tanker explosion during loading

- Bunga Alpinia on fire

- Kapal Tanker Bunga Alpinia MISC Meletup/Terbakar Di Labuan

- MT Bunga Alpinia Fire

- Ship Fire Fighting

- Ship Fire

- MV Stolt Valor

- Chemical Tanker Explosion

- Ship Hits Bridge

- Emma Maersk on Fire - World's Largest Container Ship

- Collision at Sea

- Gibraltar storm causes ship collision - Part I

- Gibraltar storm causes ship collision - Part II

- Ship collision: "Grand Rodosi" crushes "Apollo S"

- Crash of two big ships inside the sea

- Container ship collision during manoeuvre in port

- Collision 2 sea ships on river crossing in Holland

- Ship sinks after collision

Documentation

- E.U. Strategic Fuel Reserves Directives 2012

- E.U. Strategic Fuel Reserves Directives 2006

- Protección de Infraestructuras Estratégicas y Críticas en la U.E. (SPA)

- Institute of Petroleum - Guidelines for Soil, Groundwater and Surface Water Protection & Vapours Emissions

- Ley de Hidrocarburos y de Seguridad Nacional de Abastecimiento (SPA)

- Protección de Refinerías (SPA)

- Almacenamiento Inflamables Combustibes (SPA)

- Almacenamiento Productos Químicos (SPA)

- Directiva del Parlamento Europeo y del Consejo 94/9/CE, relativo a los aparatos y sistemas de protección para uso en atmósferas potencialmente explosivas (SPA)

Reports

Gas Cylinders used as Terrorist Bombs & Rocket Launchers

- Gas Cylinders Mounted on Shells and Fired

- A huge fire caught Gas bottles Store

- Gas canister bombs cause three small explosions in Athens

- Terrorists blowing up a gas cylinder in Shahrakan

- Policemen killed by blowing gas cylinder - Bahrain

- Car bomb explodes outside Sunni mosque in Bahrain

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects