TK-Meteor 6000

Ecological Portable Recycling Plant

TK-Meteor 6000 Crude Oil, Burnt Oils/Fats Contaminated, Environmental Recycling Rubber Tyre/Plastic Ecological Portable Plant with Fuel Refinery & Shredder Technology

Meteor 6000 - Portable recycling plant for the generation of biodiesel, fuels and electricity by recycling of crude oils, burnt fats & oils, contaminated land-environments due to oil spills, tyres and/or plastics through closed loop production technology and production systems.

INTRODUCTION

Technokontrol R&D is committed decisively to the protection and long term prevention to damage our global environment due to bad industrial practices. Due to this reason Technokontrol has developed our unique TK-Meteor 6000 Crude Oil, burnt oils/fats, contaminated land-environmental, rubber tyres & plastics ecological friendly recycling plants using our own R&D teams to create our own environmentally technological recycling plants to be at the forefront for the protection of the global environment.

Thus creating a cleaner energy bases using our never ending global stockpile of inorganic waste as plastics and rubbers, thus contributing to the improvement and safe guarding of the environment, social conditions and contamination of our water supplies for our future generations regardless of political, national, educational or economic boundries.

The benefits can´t only be seen as directly financially beneficial for the user which takes into account the income generated from the sale of produced biodiesel, electricity, steel, copper, recycled tyres, carbon credits, grants and tar for example, but also environmentally rewarding socially, logistically and politically by reducing the massive storage of inorganic waste in legal & illegal landfills around the world.

Rubber is difficult to recycle due to the procedure known as “vulcanization,” which it undergoes to attain its springy, flexible nature. Vulcanization is a curing process that involves adding sulfur to rubber, which creates stronger bonds between the rubber polymers. Due to the vulcanization method, tyres are difficult to melt for reuse and are therefore typically broken down by a mechanical process.

Plastics when compared to other materials like glass and metal, plastic polymers require greater processing (heat treating, thermal depolymerization and monomer recycling) to be recycled. Due to the high molecular weight of their large polymer chains, plastics have a low entropy of mixing.

A macro molecule interacts with its environment along its entire length, so total energy involved in mixing it is large compared to that of an organic molecule with a similar structure.

Landfill disposal Environmental Issues: Tyres are not desired at landfills, due to their large volumes and 75% void space, which quickly consumes valuable space. Tyres can trap methane gases, causing them to become buoyant, or bubble to the surface. This ‘bubbling’ effect can damage landfill liners that have been installed to help keep landfill contaminants from polluting local surface and ground water.

ENVIRONMENTAL OIL SPILLS, PETROL-CHEMICAL DAMAGE RECYCLING & THE PRODUCTION OF DIESEL FUEL FROM WASTE LAND ENVIRONMENTAL DAMAGE.

TK-METEOR 6000 TECHNOLOGICAL CHARACTERISTICS

Pyrolytic Oven

- Capacity of 3000 kg / day of crude oils, waste tyres or plastic compact.

- Stainless steel, ceramic and fiber thermal protective materials

- Technokontrol Heat resistant protection panels & materials

- Electric heating system by conduction and / or convection.

- Cylindrical metal tank for raw material plant feeding systems

- Collection system of black carbon / coal produced in the process

Deposits Thermal Control Systems

- System to control the temperature once decomposed pneumatic or plastics left over produced powders, gases and others.

Separation Tank with Filtering of Harmful Gases

- Inner piping systems to filter & to separate gases, biodiesel, oils, etc.

- Process repeated 4 times.

Tank Gas Purification Systems

- System which is used to purify the gases produced during the process.

Oil Storage Tank

- Storage of crude produced with output for external filling deposits. The tank has a capacity of 3,000 liters (modifiable to larger amounts).

Technokontrol Anti-Explosion Fuel tanks

- Anti-explosion technology fuel tanks against terrorism /sabotage/ accidents.

Technokontrol Anti-Slosh fuel Tanks

- Easy transportable of loaded fuel tanks to and off vessels/transports which inside liquids fuels will not “slosh” especially important for on ship recycling barrages or ships.

Technokontrol Anti-Heat/Fire Protection Safety Panels

- In the event of fire/heat these panels can resist up to 1600ºc for up to three hours which will protect fuel deposits and machinery in fires.

Refinery Plant & Technology (Inclusive)

- Refinery plant for oil refinering to obtain mainly crude but adaptable to produce diesel, gasoline, kerosene or light/heavy oils. (Oil Cracking technology)

Tyres and Plastic Crusher / Shreddar Machinery (Inclusive)

- Machine used to chop the residue before being fed into the process.

Motors, valves, and other basic operational parts and spares (Inclusive)

Transportable & Logistical Options

When designing the plant we took into account its portability. There is an option to place the entire system into shipping containers 40 "foot to optimize transport by rail, land, sea or air.

Plant Raw Material Feeding Requirements:

Material requirements for the TK-Meteor 6000 to function optimally are:

- 3000 kg of crushed material (tyre or plastic)

- Compacted densities between 640 and 840 kg/m3

The TK-Meteor 6000 recycling plant needs its own shredder machinery which we include in the package to prepare the raw material before being placed into the oven. Thus avoiding loss of production time and financial purchasing, shipping, imports, logistical costs to obtain these raw materials as plastics/rubber tyres at least financially with at least no purchase costs to the user, but also possibly receiving a financial income as grants/payments especially in Europe for recycling these types of highly contaminating inorganic waste types.

This manufacturing process needs at least 4 tanks of shredded/crushed raw material to have prepared to avoid production stoppages. In the event of not having a crusher/shredder operational at any time due to servicing or repairs, there must be at least 18 tons of grinding/shreddered stock ready for immediate use at the plant.

In the refining of crude oil we include our own TK-refinery plant where you can produce one’s own fuels such as crude, diesel, gasoline, kerosene stoves/light oils and heavy oils for commercial or industrial use.

TK METEOR 6000 Electricity Generating Plant

In the event of wishing to generate electricity, the plant may be used driven by gas generators and biodiesel produced by the plant which is capable of rotating with very little magnetic resistance, thus allowing the production of low cost electric power supply and being extremely energy efficient at the same time of still recycling the un-organic materials.

A technical data sheet will follow to explain these concepts and to facilitate a better understanding of the entire production system and plant technology:

FINANCIAL & TECHNICAL ADVANTAGES OF THE TK-METEOR 6000

- Income from funds generated from financial carbon credits, environmental grants for recycling tyres and plastics from governments or private institutions.

- No use of organic material such as wheat, plants, food or wood used or required

- Income from the sale of Biodiesel (41.850) liters / month)

- Income from the sale of Electricity (as plant configuration)

- Income from the sale of Carbon Black (31,620 kg / month)

- Income from the sale of Iron/steel (12,090 kg / month)

- Income from recycling environmentally toxic materials/inorganic

- Reduction of current landfills space and logistical & transport costs

- Production of clean green energy for electricity power production

- Zero environmental emissions

- Fuels energy obtained from long term recycling waste programms

- Portable and easy for transport in containers in 20”(x2) or 40”(x1) foot depending on plant size and applications

TECHNICAL DATA OF THE TK-METEOR 6000 (A) TYRES & (B)PLASTIC PLANTS

- Daily Capacity: 3,000 kg

- Operating time per cycle: 22 h

- Operating Temperature: 180/240/450/500 ° C

- System Dimensions: 2,3 m x 2,8 m x 9 m

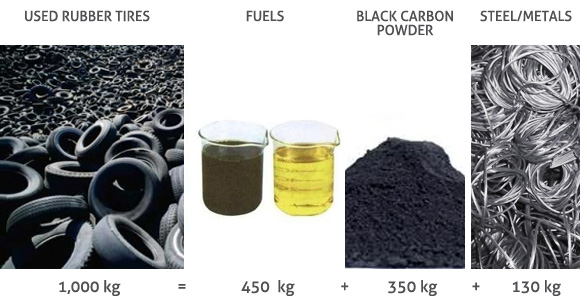

TYRES RECYCLING PRODUCTION DATA

- Oil production per load: 1350 liters

- Obtaining iron loading: 390 Kg

- Black coal production capacity: 1020 kg

- Gas Production: 0.25 m3

PLASTIC RECYCLING PRODUCTION DATA

- Oil production per load: 2.100 liters

- Obtaining iron/steel loading: 0,0 Kg

- Carbon Black Production per load: 0,0 kg

- Gas Production: 0.35 m3

CRUDE OIL/CONTAMINATED OIL SPILL LAND, BURNT OILS/FATS

ONE TON OF CRUDE OIL PRODUCES 850-1000 LITRES OF DIESEL FUEL. 1 TON CRUDE OIL=850-1000 LITRES OF DIESEL FUEL USABE FOR AUTO, GENERATORS OF FOR SALE.

The TK-Meteor 6000 Crude Oil, Tyre & Plastic Recycling Plant can be directly used for the production and sale of crude oil, iron and carbon black, but also may be the used to generate clean recycled electricity from inorganic waste.

TK-METEOR RECYCLYING RUBBER/PLASTIC PLANT

SIX TON RECYCYLING PLANT FOR NORMAL-LARGE & SUPERLARGE RUBBER SIZED TYES TRANSPORTABLE IN FOUR 40”FOOT CONTAINERS MODEL TK-METEOR 6000

RECYLING TRANSPORTABLE RUBBER / PLASTIC PLANT TK-METEOR 6000

The TK-Meteor 6000/ is a portable rubber tyre recycling plant built into four 40”foot containers used for the generation of crude oil and gas, with also of the advantage to obtain black carbon powder and the steel metal rings/cables inside the rubber tyres capable of recycling up to 10,000 kg of tyres per day of production per plant.

This plant is specially made to obtain maximum production of the total recycling process of any type of rubber plant and especially having the possibility of using the metal steel and other recycled materials obtained through this production/recycling process which benefits the protection of the environment and reduces/solves the continuous worries of the need of large storage areas especially for tyres of all types and sizes around our cities in legal and illegal landfills.

Due to its mobility of the plant we can deliver and install this plant anywhere in the world and it can be transported in four 40” foot containers by road, sea or by air. The TK-Meteor 6000 is the first fully portable incorporated rubber tyre recycling plant with its own refinery and shredding plant all inclusive in the world.

MOST IMPORTANT TECHNICAL & PRODUCTION DATA

- Totally built in stainless steel V2A

- Closed circuit production systems for no emissions.

- Operable the 24hours/7 days/365 days of the year.

- Up to 2190 Tons processed per year (180 Tons monthly)

- Simple inter-connecting of containers for quick reassembly

- All technical parametres controlled electronically

- Floating oven systems with no chimney using up to 50 kw

- Oven exterior heat reduction exterior of up to 94% (< 40ºC)

- Turning systems with triple-phase connection of 3 kw at 3,5 rpm

- Thermal heating control system to process the production of crude oil with a power need of 3kw.

- Trolley transport systems to carry and to deliver all size tyres to the production section.

- European Union manufactured plant with CE seal of production.

- Maximum production of 3000 litres per complete cycle.

- Maximum production of 1.200 kg of steel per complete cycle.

- Maximum production of 2.400 kg of black carbon per complete cycle.

- Maximum production of 0,6 m3 of per complete cycle.

- Installation of passive and active security and safety technology.

- Only 3 operators needed to operate plant per shift.

- Maximum size of rubber tyre shreddered /crushed pellets of 1-3 cm.

- Valves and control systems to control production velocity.

- All electronics easily installed and in panel format for easy control and use.

- No "TAR" or "TAR" based waste due to our exclusive "clean" recycling technology. (Please view photos after working recycling programme )

- Carbon Black Dust/powder used for manufacturing of "New Rubber Tyres", "Anti-Radar Detection Materials/Paints", "High Intensity Solar Panels", etc.

TK-METEOR 6000 TECHNICAL & OPERATIONAL DATA

DIMENSIONS OF INSTALLED OPERATIONAL UNITS OF THE PLANTS

| Dimension of the containers (2x units) | Height Width Length |

2,45m 2,37m 6m |

| Dimension needed to install plant | Minimum | 95 m2 |

| Dimensions of Container nº1 | ||

| Oven | Volume diameter length |

10 m3 1,82m 5,2m |

| Daily production capacity | kg | 6000 |

| Minimum production stock of | kg | 84,000 |

| Recommend rubber tyres shredded pellet size | cm | 1-3 |

| Electric energy consumption | kw | 50 |

| Thermal heating sensors units 4 | units | 4 |

| Electronic control systems | yes | |

| Speed of internal turning | rpm | 3,5 |

| Full cycle hourly production | hours | 24 |

| Inside production temperature | ºC | 500 |

| Exterior temperature less than | ºC | <40 |

| Dimensions of Container nº3-4 | ||

| Cooling Systems | Height Width Depth |

|

| Plant Material made of: | Stainless Steel V2A | |

| Gross weight | kg | 350 |

| Cooling fluid | H2O | |

| Cooling systems energy consumption | Kw | 3 |

| Control sensors | Unit | 2 |

| Storage Systems for Crude Production | Height Width Depth |

1m 2,1 m 0,6m |

| Machinery Material made of: | Stainless Steel V2A | |

| Gross weight | kg | 270 |

| Storage capacity | liters | 1200 |

| Pumping energy requirements | 0,3 | kw |

| Control systems | units | 2 |

| Anti-Acid Technology | Height Width Depth |

|

| Machinery material made of: | Stainless steel V2A | |

| Gross Weight | kg | 290 |

| Re-circulating unit | litres/min | 70 |

| Electric energy impulsion systems use | Kw | 1,5 |

| Control sensor unit | Units | 1 |

| Eliminating-Fumes/odors Systems | Height Width Depth |

|

| Machinery material made of: | Stainless Steel V2A | |

| Gross Weight | Kg | 220 |

| Gas Purification System | Height Width Depth |

|

| Machinery material made of: | Stainless Steel V2A | |

| Gross Weight | kg | 145 |

| Re-circulating Capacity | Litres/min | 70 |

| Electric Energy Impulsion consumption | kw | 1,5 |

| Control Sensors | Units | 2 |

TK-METEOR 6000 OPERATIONAL PHOTOS & DATA AFTER RECYCLING PROCESS/RECYCLE USAGE OF MATERIALS

VIEW

Inside view after use of "Oven Cylinder" after recycling cycle of the TK-Meteor 6000.

Black carbon dust/powder from rubber tyres on sides of the "Oven cylinder" and the steel cable metal visible is clean for immediate re-use/recycling.

Gas created inside “Oven Cylinder" makes the whole process nearly energy free and power auto-sufficient. (0.25M3-0.35M3 gas production /per cycle)

Black carbon can also be used to manufacture "Low Radar Detection Special Materials-Paints", "High Intensity Solar Panels", "Specialist Aeronautical Alloys", "Re-usable for the manufacturing of new rubber tyres", etc.

The left over waste has no traces of any types of "HEAVY TAR", or similar types of "TARS" which make this recycling process extremely difficult making our TK-Meteor 6000 unique and exclusive with Technokontrol´s technology in this field of environmental protection and prevention.

Refinery Unit TK-MRU6000 for 6000 Crude Oil Production

The TK-MRU6000 refinery is a unit used to refine crude oil to obtain diesel fuels. Its production is of 10,000 litres per day (cycle) with a daily net production of 91%.

The TK-MRU6000 refinery plant has been designed to make crude but with some technical changes including simple “cracking technology” we can produce diesel, gasoline, kerosene heavy/light oils for heating systems, for example.

It has a continuous production system not needing to load up any crude oil fuel tank of fuel deposits other than the already included anti-explosion protected TK- Storage Fuel Tank.

The TK-METEOR 6000 and TK-MRU6000 are portable and work side by side.

Main Technical & Features:

- Made of stainless steel V2A

- Closed circuit production. No external emissions.

- Refinering at 160 litres per hour.

- Thermal heat sensors controlling operations.

- Continuous refinering process.

- Totally electronically controlled.

- Oven turning systems working at 3 kw a 3,5 rpm.

- Thermal heating control to obtain diesel fuel needing 15kw of energy.

- European Union manufactured with CE seal of manufacturing.

Refinery dimensions

| Dimensions of the refinery | Height Width Length |

2m 1m 4m |

| Dimensions of the refinery required space | Minimum | 15m2 |

| Daily loading capacity | Litres | 4,000 |

| Thermal Heat Sensors | Units | 3 |

| Electronic control systems | yes | |

| Daily operational hours | Hours | 22/24 |

| Working Temperature | ºC | +300 |

| Gross Weight | kg | 510 |

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

TK-Meteor 4000/6000

TK-Global Environment

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Documentation

- New Energy Economy

- Major Hazards with C02

- Energy Developments

- Emerging Energies

- Sub-sectoral Environmental Guidelines Petrol/Gasoline Retailing

- Directive 2001/81/EC of the European Parliament and of the Council of 23 October 2001

- Institute of Petroleum - Guidelines for Soil, Groundwater and Surface Water Protection & Vapours Emissions

- Directiva 2009/31/CE del Parlamento Europeo 2009

- Medio ambiente Real Decreto 455/2012, de 5 de marzo, por el que se establecen las medidas destinadas a reducir la cantidad de vapores de gasolina emitidos a la atmósfera durante el repostaje de los vehículos de motor en las estaciones de servicio

- Reducing the evaporation of stored Iraqi crude oil

Evaporation losses for covered with surfactant, covered with polymer, and uncovered surface of blend crude oil were (0.45%) at 24 °C for 96 hours evaporation time

- Evaporation Loss Measurement from Storage Tanks

- Estimation of the Petrochemical Evaporation Loss from Fixed Roof Storage Tanks

Regarding the crude oil, the working loss is about 75% of all other organic liquids under same conditions

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects