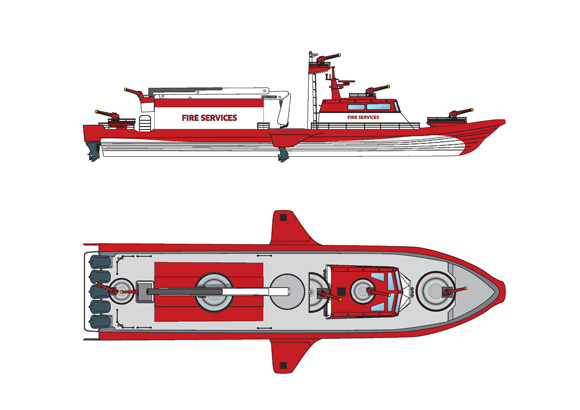

King Shark XIII

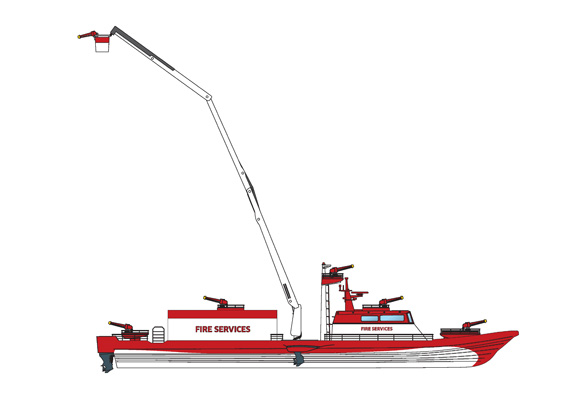

Fire Services - Long Ladder

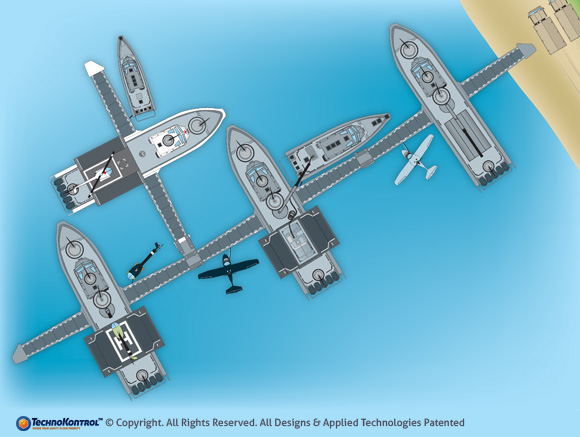

TechnoKontrol King Shark XIII

Fire Services - Long Ladder

Technokontrol © Copyright. All Rights Reserved. All Designs & Applied Technologies Patented

| MAIN DATA | |

|---|---|

| LOA | 26-35 m |

| BEAM | 3,60-6,10 m |

| DRAFT | 0,7-1,30 m |

| PETROL CAPACITY | 2.250-6.000 lts |

| PASSENGERS | 12 |

| ENGINES | 5 X outboard Yamaha V8 F350 (Yamaha 350 BHP=1750BHP) |

| MAX. SPEED (50% LOAD CONDITION) | 25 -65 KNT (Depending on final weight on vessel) |

VARIOUS

- Anti-explosion fuel tanks (FUEL TANK CAPACITY 2,250-6,000 LITRES).

- Anti-oxidation fuel tanks.(LONG LIFE FUEL TANKS-LOW MAINTENANCE).

- Anti-Slosh/fuel movement inside fuel tanks to protect vessel.(GREAT STABLILITY-TANK PROTECTION)

- Anti-Algae growth fuel tanks for low maintenance. (CLEANER FUEL/HIGHER FUEL QUALITY DUE TO FUEL FILTRATION AND DEBRIEE SEPERATION).

- Special Safety fuel filtering technology to increase speed (SAFETY FUEL FILTERS NON-EXPLOSION.)

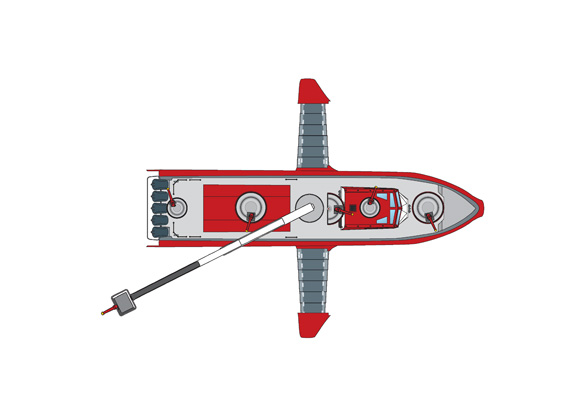

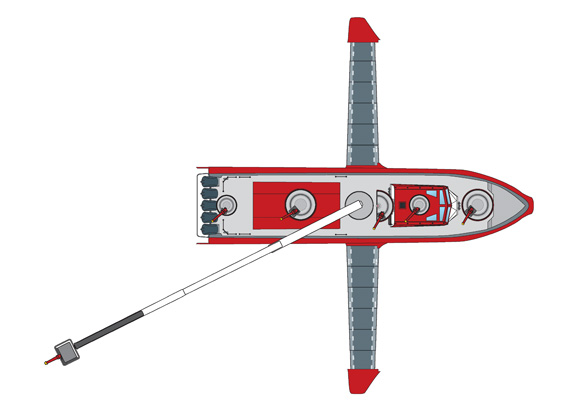

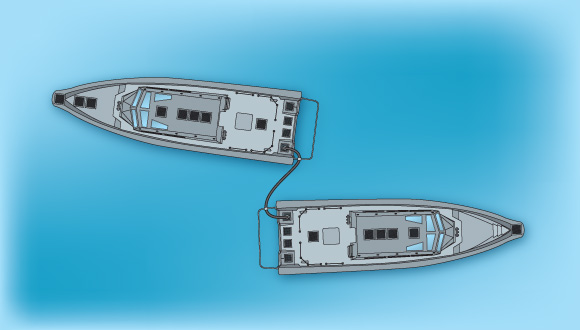

- Extendible “Aileron Extension Platforms (TK-Patented Technology)” to increase vessel stability in loading/un-loading/aircraft/container operational usage.

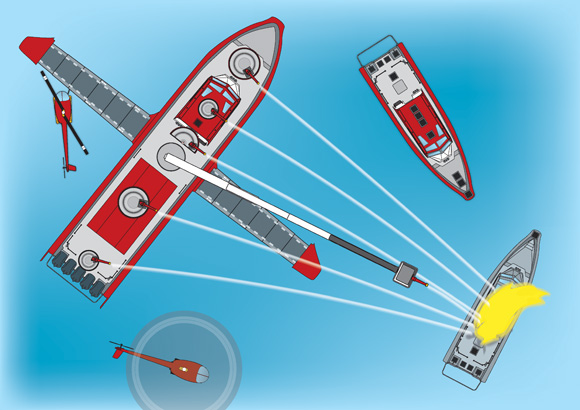

- Extendible “Aileron Extension Platforms (Patented Technology”) to attach different types of vessels in creating floating, mobile, operational bases for any type of operations from creating “Drug Enforcement Controls”, “Medical/Medi-Vac ELZ/LZ”, “Telecomunications bases”, “Mixed usage operational landing forces/Naval-Aerial -Terrestrial Bridge heads”

- Bullet proof level III-VII+ cabin and internal protection(HUMAN & ASSET PROTECTION PARAMOUNT)

- Special bullet level III-VII+ Proof engine covering(PROTECTION COVERING TO REDUCE BULLET SHOTS)

- Anti-Electomagnetic Pulse cabin/Anti-EMPS(ELECTRONIC WARFARE OR SOLAR RADIATION DAMAGE-OPTIONAL)

- Includes: 150 units x20 litres anti-explosion fuel safety Jerry cans colour metalic blue or similar (Total mobile fuel protected in TK- Safety Jerry Cans of 3,000 litres(Allowing offshore refueling by other vessels during patrols or on active operations thus not needing to refuel at port/harbour).

- Manual/electric TK-fuel pumping system to refuel from TK-Safety Jerry Cans to vessel for refuelling offshore at sea/river.

- Rubber anti-explosion/fire flexible fuel pipleline to refuel of 20 metres lengthto any refueling source.

- Vessel color codes to be chosen by the client .

- Unsinkable boat, by means of non inflatable and very low density tubes/fenders, furthermore of the flotation volumes.

- Vacuum infusion HI-tech composite for hull, cabin and deck.

- Stem protected by Bullet/explosion proof materials.

- Bow rubber/aluminum.

- Pusher/fender rubber.

- Aft protection for the engines.

- Hight temperature resistant anti-skid finish on the walkways.

Extendible "Aileron Extension Platforms" for latter manouver balance, attaching different types of vessels or shore docking

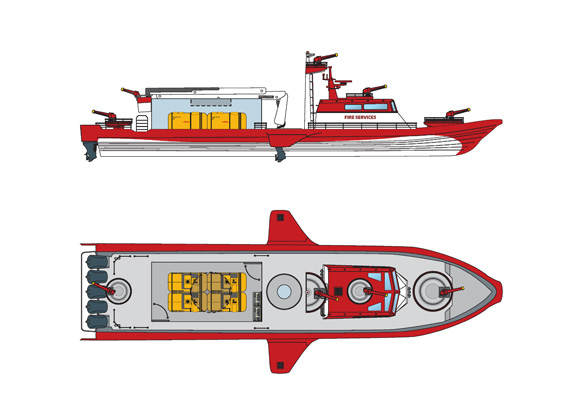

Ecological foam containers

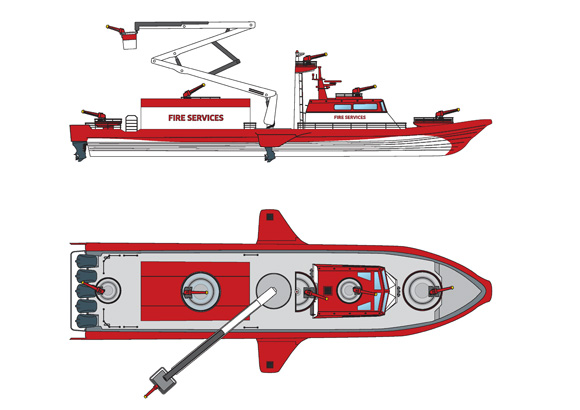

Unfolding latter and undocking central water cannon

Extended latter reach

Ailerons extend to provide balance while operating latter

Huge pumping power to fight dangerous fires

Different types of attached vessels creating a floating, mobile, operational base for any type of operations.

DISTRIBUTION

- Reinforced areas for monitors fixation.

- External locker in the cabin bow part.

- 6/12 mitigation seats with belts.

- Interior fridge.

- Internal locker.

- Chemical WC.

- Aft cockpit.

- Bilge Access.

- Heavy Duty Protected Onboard Telescopic Crane System.

- Multi-usage Container Technology (TK-Patented) to inter-change operational usage.

King Shark XIII is a larger type emergency vessel, being able to move quicker at sea but having also greater operational range, speed and heavier fire power.

CABIN

- Level III-VII+ bullet proof cabin & roof.

- Anti-EMPS/Electromagnetic Pulse cabin Protection Technology against solar radiation (Optional). Flares or terrorist/military activities/anti-explosion.

- Bullet proof level III-VI+ cabin windows

- Law enforcement, Navy patrol, Armed Forces exterior emergency lights.

- High temperature resistant windows.

- Air conditioned cabin.

- Audio speakers.

- Roof LED lights.

- Bridge station.

- Control panel.

- Electrical distribution control screen.

- Security and alarms system.

- 6/12 high speed seats with belts.

- WC chemical.

- Fridge.

- Windows (frontal with wipers).

- Emergency cabin exit over pilots.

METAL PARTS

- Frontal access gangway.

- 4 bollards.

- Rails around the cabin.

- Rails around the cockpit.

- Hooks over the roof of the cabin.

- Access to the engine room.

- Bilge ventilation grills.

- Electronic devices and lights supports.

- Outboard engines protection.

- Towing point.

- 4 hard points for lift the boat.

- 2/6 metal mounts (cabin roof /aft) to install armament as machine guns or grenade launchers.

- Heavy Duty Onboard telescopic Crane System

- Vessel unique “Crow Nest” for observation and light/heavy duty armament mounts for manual/remote control/automatic firing 360º armed/missile vessel protection.

- Multi-use Container allocation points for incorporation into vessel hull.(TK-Patented)

INSTALLATIONS

BILGE

- Inverter.

- Battery charger.

- Air conditioning chiller.

- Service and engines batteries.

- Bilge pumps (2 automatic, 1 manual) Automatic fire fighting cylinder.

- Sound transducer.

- Natural ventilation.

PETROL TANK SPACE

- Isolated space for the aluminum petrol tank 2,250-6,000 litres installation.

- Natural ventilation with isolating system for emergencies.

- Anti-explosion fuel tanks.

- Anti-oxidation fuel tanks.

- Anti-Slosh/fuel movement inside fuel tanks to protect vessel.

- Anti-Algae growth fuel tanks for low maintenance & fuel filtering.

- Special Safety fuel fitering technology to increase speed.

- Bullet proof level III-VII+cabin and internal protection.

- Special bullet level III-VII+ Proof engine covering.

- Anti-Electomagnetic Pulse cabin/Anti-EMPS.(Optional)

- Automatic fire fighting cylinders.

- Drain valve communicated with the engine room.

ELECTRIC SYSTEM

- DC INSTALLATION 12V

- 3 wire electrical distribution

- Batteries for services and generator.

- Emergency batteries for VHF.

- LED lights on the floor and cabin ceiling.

- Navigation lights.

- 3 remote operation search lights.

- 4 work focus.

- Electronic devices. Fridge 230

INTERNAL SHORE CONNECTION

Table I

| Dimesions of International Shore Connection | MKS units | US units | |

|---|---|---|---|

| Outside diameter | 178 mm | 7 in. | |

| Inside diameter | 64 mm | 2.5 in. | |

| Bolt circle diameter | 132 mm | 5.2 in. | |

| Slots in flange | 4 holes 19 mm (0.75 in.) in diameter spaced equidistant on a bolt circle of the above diameter slotted to the flange periphery | ||

| Flange thickness | 14.5 mm minimum | 0.57 in. minimum | |

| Bolts and nuts | 4 each of 1|6 mm diameter, 50 mm in lenght |

4 each of 0.63 in diameter, 1.97 in. in lenght |

|

According to 4-7-3; 1.19.4 ABS, this connection shall be of material suitable for 10.5 kg/cm2 pressure.

PROPULSION

ENGINES

5 X outboard (Yamaha Pro FourStroke F350 V8 DOHX 32V-350BHP)

Hydro-Jet power systems also available with diesel, petrol or gas fueled engines.

POWER

5 X 350 bhp Yamaha= 1,750 bhp in total per vessel.

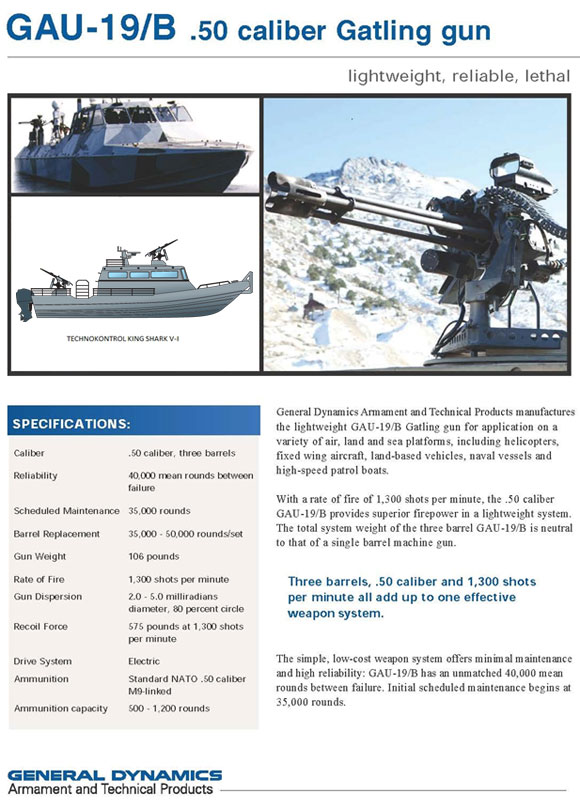

ARMAMENT (OPTIONAL)

KING SHARKS have from two to eight machine gun mounts which are located on top of the cabin roof and on the aft area of the vessel. We recommend the installation of 2/6 x machine guns of 30mm/Grenade launchers. These units are optional and can be operated by navy personel or automatic shooting technology from inside of the cabin via a joystick and video camera attack systems which aren´t included in this proposal.

1.-KING SHARK I SONOBUOYS:

The option of also sound-movement sonobuoys, anti-submarine sonobuoys, tracking systems, environmental control technology can also be adapted for futher navy or surveillance options.

2.-KING SHARK I ARMAMENT (OPTIONAL)

The cabin machine gun mount can also be used as a grenade launcher as the MK19 40mm automatic granade launcher manufactured by the USA or similar.

Technokontrol Maritime & Technokontrol "Black Night Viper Military ", has eighteen main type of Navy/Military/Law Enforcement Vessels, "King Sharks I, II, III, IV, V, VI, VII, VIII,XIX,X,XI,XII,XIII,XIV,XV,XVI,XVII,XVIII"

Technokontrol can design any vessel for our clients needs, however, these are te types of vessels we are currently manufacturing or designing and are capable of quick delivery programs and using the best and most modern military and non-military technologies.

We design our vessels in mind always with the clients operational needs being paramount thus some clients wishing range, fire power, cost, maintenance and running costs, hourly use cost,high durablity, shallow water, salt water or river water usage, mix usage, armament, troop movements, as their paramount operational requirements and thus designing and building the "exact final vessel" with the best possible technology and safety features for our clients needs.

KING SHARK VESSELS VERSIONS

King Shark I "Light Armoured Patrol Vessels"

Is more suitable for rivers, river deltas, coastal control, etc.

King Shark II "Heavy Armoured Patrol Vessels"

Is a larger type patrol vessel this being able to move quicker at sea but having also having the greater operational range, speed and heavier fire power.

King Shark III, "Eagle Eye Carriers"

An ideal vessel to carry its own specialist "Eagle Eye Aircraft" for extreme long range surveillance of over 1,500 km per flight which is currently at its final design stages and to which we can mix "sea and aerial operations" at a fraction of the cost of normal navy/military"aerial-sea operational vessels". The client wil be able to select and any "Eagle Eye Aircraft" depending on their operational needs from surveillnace to defence or to research activities.

King Shark "Troop Assault Vessels"

Especially designed as a fully high speed, well protected and special operations troop carrier of up to 24-30 troops.

King Shark "Logistal Fuel/Supply/Carriers"

For all types of logistical use and especially for refueling, arming and transporting supplies to other "King Sharks" at sea or at extreme locations where this can´t be done with normal ground logistics as ports, harbours, fuels vesels,etc. Including their "secretive"use for refueling/supplying special or long term law enforcement, navy or military observation, surveillance, defence or attack operations without depending on other personell, civilians and allowing full covert operations to continue forl ong term operations.

King Shark "Missile Launchers"

A specially designed vessel where missiles can be transported and launched in any types of waters and even using lazer guided missile technology. Ideal missile platform and totally built to withstand all types of "rocket propelled jet blast". Ideal fo the first or final "punch" in any water based operations especially against larger vessels, enemy ground bases or even drug manufacturing bases or industries.

King Shark "Mine/Sonobouy Launchers"

These vessels have the capacity to carry and to launch mines and information/research based sonobouys in rivers and at sea for tracking operations of other vessels, ships, submarines, piracy movements, etc.

1.-TECHNOKONTROL SONOBUOYS – TECHNOKONTROL TECHNOLOGIES

What is SONAR or SODAR Technology?

Sonar (Sound Navigation and Ranging) is a technique that uses sound propagation (usually underwater, as in submarine navigation) to navigate, communicate with or detect objects on or under the surface of the water, such as other vessels. Two types of technology share the name "sonar": passive sonar is essentially listening for the sound made by vessels; active sonar is emitting pulses of sounds and listening for echoes. Sonar may be used as a means of acoustic location and of measurement of the echo characteristics of "targets" in the water.

Acoustic location in air was used before the introduction of radar. Sonar may also be used in air for robot navigation, and SODAR (an upward looking in-air sonar) is used for atmospheric investigations. The term sonar is also used for the equipment used to generate and receive the sound. The acoustic frequencies used in sonar systems vary from very low (infrasonic) to extremely high (ultrasonic). The study of underwater sound is known as underwater acoustics or hydroacoustics.

What is Active and Passive Sonar or SODAR Technology?

Active sonar gives the exact bearing to a target, and sometimes the range. Active sonar works the same way as radar: a signal is emitted. The sound wave then travels in many directions from the emitting object. When it hits an object, the sound wave is then reflected in many other directions. Some of the energy will travel back to the emitting source. The echo will enable the sonar system or technician to calculate, with many factors such as the frequency, the energy of the received signal, the depth, the water temperature, the position of the reflecting object, etc. Active sonar is used when the platform commander determines that it is more important to determine the position of a possible threat submarine than it is to conceal his own position. With surface ships it might be assumed that the threat is already tracking the ship with satellite data. Any vessel around the emitting sonar will detect the emission. Having heard the signal, it is easy to identify the sonar equipment used (usually with its frequency) and its position (with the sound wave's energy). Active sonar is similar to radar in that, while it allows detection of targets at a certain range, it also enables the emitter to be detected at a far greater range, which is undesirable.

Since active sonar reveals the presence and position of the operator, and does not allow exact classification of targets, it is used by fast (planes, helicopters) and by noisy platforms (most surface ships) but rarely by submarines. When active sonar is used by surface ships or submarines, it is typically activated very briefly at intermittent periods to minimize the risk of detection. Consequently active sonar is normally considered a backup to passive sonar. In aircraft, active sonar is used in the form of disposable sonobuoys that are dropped in the aircraft's patrol area or in the vicinity of possible enemy sonar contacts.

Passive sonar has several advantages. Most importantly, it is silent. If the target radiated noise level is high enough, it can have a greater range than active sonar, and allows the target to be identified. Since any motorized object makes some noise, it may in principle be detected, depending on the level of noise emitted and the ambient noise level in the area, as well as the technology used. To simplify, passive sonar "sees" around the ship using it. On a submarine, nose-mounted passive sonar detects in directions of about 270°, centered on the ship's alignment, the hull-mounted array of about 160° on each side, and the towed array of a full 360°.

The invisible areas are due to the ship's own interference. Once a signal is detected in a certain direction it is possible to zoom in and analyze the signal received (narrowband analysis). This is generally done using a Fourier transform to show the different frequencies making up the sound. Since every engine makes a specific sound, it is straightforward to identify the object. Databases of unique engine sounds are part of what is known as acoustic intelligence or ACINT.

Another use of passive sonar is to determine the target's trajectory. This process is called Target Motion Analysis (TMA), and the resultant "solution" is the target's range, course, and speed. TMA is done by marking from which direction the sound comes at different times, and comparing the motion with that of the operator's own ship. Changes in relative motion are analyzed using standard geometrical techniques along with some assumptions about limiting cases.

Passive sonar is stealthy and very useful. However, it requires high-tech electronic components and is costly. It is generally deployed on expensive ships in the form of arrays to enhance detection. Surface ships use it to good effect; it is even better used by submarines, and it is also used by airplanes and helicopters, mostly to a "surprise effect", since submarines can hide under thermal layers. If a submarine's commander believes he is alone, he may bring his boat closer to the surface and be easier to detect, or go deeper and faster, and thus make more sound.

Examples of sonar applications in military use are given below. Many of the civil uses given in the following section may also be applicable to naval use.

Examples of sonar applications in military use are given below. Many of the civil uses given in the following section may also be applicable to naval use.

TK-King Shark I Sonobuoy Detection/Tracking/Anti Submarine Technology

What are Technokontrol Sonobuoys Technologies?

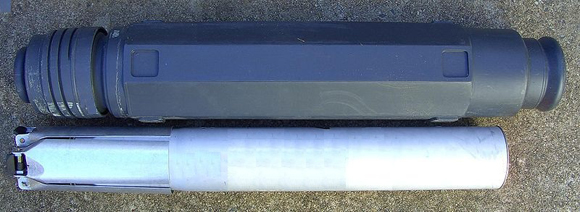

The Technokontrol Sonobuoy Technology is a small (typically 10-20 centimetres, in diameter and 80 /95 cm long) expendable sonar system that is dropped/ejected/launched from aircraft or ships conducting anti-submarine warfare or underwater acoustic research.

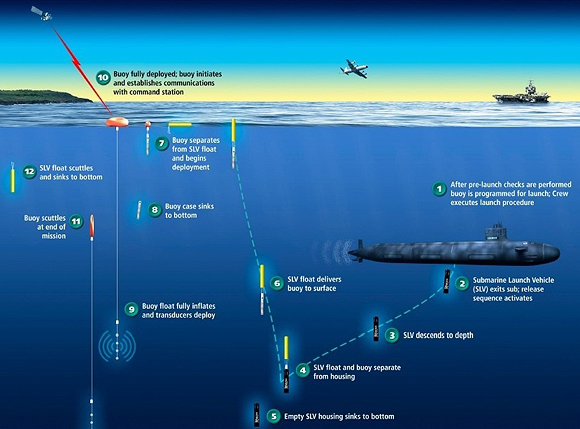

The KING SHARK can deploy the sonobuoys by means of simple ejection from the vessel or can be laid on the sea surface by manual means. These are deployed in canisters and are deployed upon water impact or with timer technology. An inflatable surface float with a radio transmitter remains on the surface for communication with the aircraft, while one or more hydrophone sensors and stabilizing equipment descend below the surface to a selected depth that is variable, depending on environmental conditions and the search pattern. The buoy relays acoustic information from its hydrophone(s) via UHF/VHF radio to operators on board the aircraft.

Technokontrols Concept of Operation (TK-CONOPs)

Types of Technokontrol Sonobouys?

Active sonobuoys

Emit sound energy (pings) into the water and listen for the returning echo before transmitting—usually range and bearing—information via UHF/VHF radio to a receiving ship or aircraft. The original active sonobuoys pinged continuously after deployment for a predetermined period of time. Later, Command Activated Sonobuoy System (CASS) sonobuoys allowed the aircraft to trigger pings (or buoy scuttling) via a radio link. This evolved into DICASS (Directional CASS) in which the return echo contained bearing as well as range data. Sonobuoys are classified into three categories: active, passive and special purpose.

Passive sonobuoys

Emit nothing into the water, but rather listen, waiting for sound waves (for instance, power plant, propeller or door-closing and other noises) from ships or submarines, or other acoustic signals of interest, to reach the hydrophone. The sound is then transmitted via UHF/VHF radio to a receiving ship or aircraft.

Special purpose sonobuoys

Relay various types of oceanographic data to a ship, aircraft, or satellite. There are three types of special-purpose sonobuoys in use today. These sonobuoys are not designed for use in submarine detection or localization.

- a)-BT—Thebathythermobuoy(BT) Relay bathythermographic or salinity readings, or both, at various depths.

- b)-SAR—The search and rescue (SAR) buoy is designed to operate as a floating RF beacon. As such, it is used to assist in marking the location of an aircraft crash site, a sunken ship, or survivors at sea.

- c)-ATAC/DLC—Air transportable communication (ATAC) and down-link communication (DLC) buoys, such as the UQC, or "gertrude", are intended for use as a means of communication between an aircraft and a submarine, or between a ship and a submarine. This information is analysed by computers, acoustic operators and TACCOs to interpret the sonobuoy information.

Active and/or passive sonobuoys may be laid in large fields or barriers for initial detection. Active buoys may then be used for precise location. Passive buoys may also be deployed on the surface in patterns to allow relatively precise location by triangulation. Multiple aircraft or ships monitor the pattern either passively listening or actively transmitting to drive the submarine into the sonar net. Sometimes the pattern takes the shape of a grid or other array formation and complex beam forming signal processing is used to transcend the capabilities of single, or limited numbers of, hydrophones.

The "KING SHARKS NAVY/SEA RESEARCH/ANTI-SUBMARINE PATROL VESSELS" are equipped with several different engine models options from 1200bhp to a maximum 1750bhp depending on the clients requirements, navegation conditions, range, speed, etc. (Hydro Jets or propeller)These engines are always top of the range and quality manufactured engines from "Yamaha" engines to "Mercury" engines models, however, we are at present only using fuel injection 4 stroke engines to reduce fuel consumption, contamination and especially extending refueling times and reducing maintenance costs.

2.-KING SHARK I ARMAMENT (OPTIONAL)

King Shark I /(Aft /cabin roof automatic grenade launcher).

Mk.47 (Mark 47) Striker 40 automatic grenade launcher / machine gun (USA)

Mk.47 mod.0 Advanced Lightweight Grenade Launcher (ALGL) on standard tripod.

Mk.47 mod.0 Automatic Grenade Launcher, close-up view. Image: GDATP

Mk.47 mod.0 Automatic Grenade Launcher, close-up view from the rear; note screen of electronic sighting / fire control unit. Iimage: GDATP

- Caliber: 25x59mm

- Type: gas operated, belt fed automatic grenade launcher

- Overall length: 1328 mm

- Weight: 22.7 kg complete with tripod mount and sight / fire controlunit

- Effective range: up to 2000 m against point targets, 3600 m maximum

- Rate of fire: 250 rounds per minute

Mark 47 Model 0 (mk.47 mod.0) automatic grenade launcher is short recoil operated, locked breech weapon that fires from closed bolt for improved first-shot hit probability. Weapon is air-cooled and belt fed, using standard disintegrating belts, same as Mk.19 Mod.3 launcher. Standard belts are supplied in 32 or 48 round boxes.

Weapon is equipped with newly developed Mk.108 mod.0 tripod with T&E mechanisms and brake that allows to lock weapon on pre-selected target spot. The key member of the Striker 40 system is the AN/PVG-1 Lightweight Video Sight (LVS), which offers 3X magnification TV view on target, combined with laser range finder and ballistic computer; sight also has interface connectors that allow to link it to optional thermal night sighting equipment which can be installed on the weapon; once the night sight is connected, operator can select TV or thermal picture via the single button.

The LVS allows to accurately measure the range to the target then aim the gun accurately for high first shot hit accuracy. LVS is installed on the right side of the weapon, and is controlled by the buttons and four-position "joystick" located at the rear of the receiver, between and above spade grips.

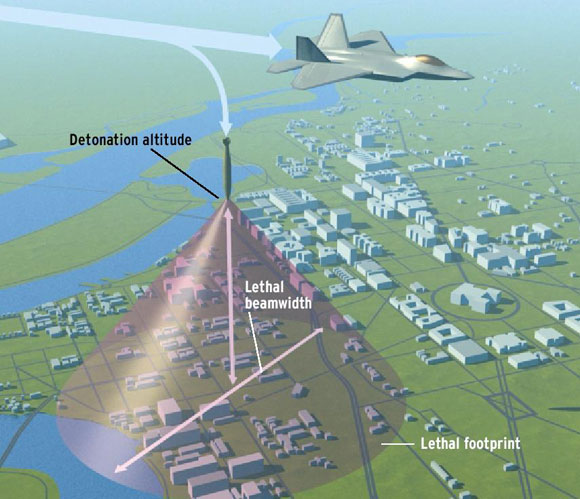

TECHNOKONTROL ANTI-EMPS DEFENCE AGAINST EMPS-BOMBS, EMPS PERSONAL CARRIED DEVICE ATTACKS AND SOLAR-FLARES OR SOLAR RADIATION

The most effective defence against electro-magnetic bombs is to prevent their delivery by destroying the launch platform or delivery vehicle, as is the case with nuclear weapons. This however may not always be possible, and therefore systems which can be expected to suffer exposure to the electro-magnetic weapons effects must be electro-magnetically hardened.

The most effective method is to wholly contain the equipment in an electrically conductive enclosure; Technokontrol has developed the Anti-EMPS Protection Panels for such protection systems termed a Faraday cages or TK-EMPS Panel Protected Bunker-Buildings, all types of vessels, ships, military bases, aircraft, ect which prevent the electro-magnetic field from gaining access to the protected equipment. However, most such equipment must communicate with and be fed with power from the outside world, and this can provide entry points via which electrical transients may enter the enclosure and effect damage. While optical fibers address this requirement for transferring data in and out, electrical power feeds remain an on-going vulnerability.

Where an electrically conductive channel must enter the enclosure, electro-magnetic arresting devices must be fitted. A range of devices exist, however care must be taken in determining their parameters to ensure that they can deal with the rise time and strength of electrical transients produced by electro-magnetic devices. Reports from the US indicate that hardening measures attuned to the behaviour of nuclear EMP bombs do not perform well when dealing with some conventional microwave electro-magnetic device designs. Thus needing to use Technokontrols Anti-EMPS Protection Technology which as being simple and effective will not need to be applied to the internal electronics of any of the devices required for protection as the whole area, zone, section will be protected for all outside EMPS and thus needing to install an antenna to continue to operate with the outside world once the danger has been overcome or passed allowing normal operations to continue if desired.

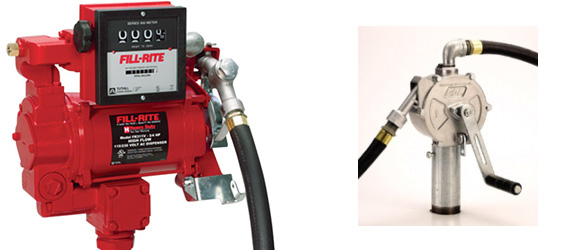

TK-AXSFV ANTI EXPLOSION SAFETY FUEL VALVE SYSTEM –REFUELING PIPELINE INTER-VESSELS / EMERGENCY REFUELING AT DOCKS / HARBOURS

We at Technokontrol have had our R&D department create and patent our very own fuel valve system (FVS), which may even contradict many physical principles but after many years of research and development we can not only prove its viability via the attached presentation, we can also prove that it is commercially viable as we already starting to sell it into local Petrol Stations throughout the world. We have also been informed (via our European Associates) that the EU are currently considering a complete overhaul and may even introduce a new tax levy on vapour contamination caused when refuelling ones vehicle.

We have included in all of our vessels the same fuel safety valves and anti explosion/fire rubber protected pipelines with Technokontrol anti-explosion alloys to have an immediate and quick operational option to refuel/transfer fuel to and from all types of vessels at sea/river especially under navy “live operations” where returing to a port/ harbour can be time consuming, costly and can stop/cancel an operation due to lack of fuel. This will provide and allow via this system that any other navy, law enforcement vessels can meet at designated locations for refueling operations at sea and to continue operations as anti-piracy or anti-terrorist.

Techno Kontrol Fueling Valve System with TK Alloys

You will be able to verify that without our valve system the refuelling amount (in Litres) taken over a 9 minute timescale and from a top loading vehicle was that of 2,914 litres meaning that the average amount of fuel entering the tank per minute was that of 323,77 litres.However, when using our FVS system and the same vehicle, the amount refuelled throughout a 6 minute timescale was that of 2,967 litres meaning that the average amount of fuel entering the tank per minute was that of 495,50 litres.The difference in litres was 171,73 litres per minute (i.e. 492,50 litres with the FVS system against 323,77 without), thus showing our systems obvious benefit within the marketplace.

Other benefits of using our product and technology can be seen as follows:

- Technokontrol can demonstrate how when our product has been installed and maintained by one of our authorized engineers that it can stop any explosion from occurring within tanks filled with Diesel, Gas, Petroleum or any other type of flammable, gaseous or liquid substance.

- Technokontrol only uses 1% of the fuel tanks full capacity for the net and 1,5% for the balls. Therefore if we use a 100 litre tank as an example, when filled with our Net it will continue to have a fuel capacity of 99 litres, and when filled with our Technokontrol balls it will have a capacity of 98.5 litres.

- Technokontrol completely avoids any oxidation within the interior of the tank.

- Technokontrol stabilises the liquid in moving tanks such as tankers, speed boats or freight transport.

- Technokontrol will provide a lifelong service and maintenance package for any Technokontrol product which has been installed and maintained by one of our authorized engineers.

- Technokontrol is compatible with all types of combustibles and does not change any of its chemical properties.

- Technokontrol cancels out any electrostatic charge.

ANTI EXPLOSION / FIRE RUBBER PROTECTED REFUELING PIPELINES

This refueling system is for:

Immediate and quick operational option to refuel/transfer fuel to and from all types of vessels at sea/river especially under navy "live operations"

TK- SAFETY ANTI-EXPLOSION JERRY CANS

Due to knowing the risk of carry on board hundreds or thousands of litres of fuel we also included 50 x 20 litres anti-explosion/fire TK-Safety Jerry cans which can be transported without any risk of bullets shots, onboard fires, explosions, cross fire,etc and via the rubber pipeline can be connected to the other vessels with the TK-Safety valves and rubber pipelines to refuel without any danger between either vessel at any location.

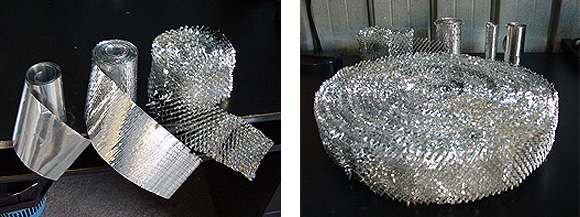

TK-AXABM ANTI-EXPLOSION ALLOY (BALL, MESH, TEXTILE & PANELS)

TechnoKontrol Alloy Safety Products

TechnoKontrol Alloy Safety products are a unique non-combustible material consisting of a specially designed metal alloy mesh mechanically produced via a patented three dimensional production system.

TechnoKontrol Safety Technology Alloys, panels and safety technology systems are comprised of patented alloy material manufactured in a three dimensional manner mechanically produced into a mesh, ball or textile format to form a unique non-combustible material that is Fire, Blast, Moisture, Corrosion, heat, sound and electromagnetic wave resistant depending for its final usage.In the case of blast, fire, heat or explosions TechnoKontrol Safety Technology Systems will perform as no other product in the market, especially, in the oil-gas-chemical industries.

As mentioned above, the TechnoKontrol Safety Technology Alloy stops the explosion of any tank filled with gasoline, diesel, gas, petroleum or any other type of flammable, gaseous or liquid substance.

In addition our TechnoKontrol Alloy only consumes(volume) a minimum 1% of the overall tanks capacity when using the net and 1.5% when using the balls. Therefore, if a 100 litres tank is filled with our alloy net, the tank has a capacity of 99 litres, and if filled with the balls, it has a capacity of 98.5 litres. Thus our TechnoKontrol Safety Alloy completely avoids the oxidation within the interior part of the tank, (if tank is new or stops increasing oxidation if already an used tank) and in turn stops explosions 100% of the time.

Our TechnoKontrol Alloy TK-Ball & TK-Mesh is exceptionally flexible, resistant to heat and once installed requires very little maintenance even within the most aggressive of atmospheres.

As per our Mission Statement, at Technokontrol we are constantly reinvesting into our Research; Development and Investigation departments so as to be able to adapt our patented alloy and manufacturing systems in order to continually expand our product lines. The following are just three examples of where you can find our specially designed products today.

TK- KING SHARK I ELECTRONICS, SYSTEMS & TECHNOLOGIES

TK-Global Electronics specially manufactured and installed technologies for TK-King Shark Vessels

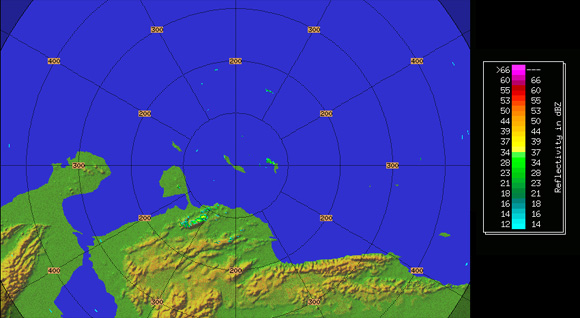

RADAR SYSTEM

Display 15” color, antena radome, 4KW

SYSTEM VOYAGER III / VOYAGER II

- With 4× optical zoom and 15x total zoom.

- Powerful, long-range daylight/lowlight color TV camera with 26× optical zoom.

- Active gyro-stabilization technologies.

- Radar Tracking.

- Internet remote control.

- Expanded interface capability.

- Automatic video tracking system.

- Temperature indication.

- Joystick Control Unit: Heated LCD Screen, User-programmable “hot key”, Home, Color, Scene, Joystick, Ethernet connectivity.

Series M Multi-sensor M-618CS. Includes:

Marine Monitor HATTELAND 15" powered 24 VDC JH15T17MMD-DA1-AAAA.

- PLOTER-SONDA Display 15" color.

- ANTENA GPS.

- CHART Navionics.

- AIS.

- Antenna.

- VHF STANDARD GX1500E.

- ANTENA RA1225 2,4mts.

- Support RA166 inox.

- Red and blue emergency lights.

- Megaphone / Audio speakers.

- Standard VLH.

- 3000E.

- 3000 E Exponential.

- Speaker 240sw.

- EMERGENCY SONOBUOY AUTOMATIC SIGNAL E100GPS.

- SART OCEAN SIGNAL S10.0

- VHF GMDSS OCEAN SIGNAL V100.

- 3 x Motorized Search Lights.

EQUIPMENT

NAVIGATION

According to international regulations. Compass, temperature, pressure and humidity gauge.

SAFETY EQUIPMENT

According to international regulations.

FIRE FIGHTING EQUIPMENT

According to international regulations.

EXTRA-SAFETY EQUIPMENT

1. Anti explosion fuel tanks (2,250-6,000 litres) Range up to 500-1,200km

EXTRA-SECURITY EQUIPMENT

2. Bullet proof cabin and windows level III-VII+

ELECTRONIC SECURITY

3. Anti-electronic magnetic Pulse in cabin/Anti EMPS.(Optional).

EMERGENCY REFUELING SYSTEMS

4. Safety TK-Pumping systems via discharge pipeline to refuel vessel to vessel offshore or out of land/port refueling locations

Emergecy vessel-to-vessel refueling system

VARIOUS

- Extra rubber protection side/hull covering to protect against docking /other vessel attachments

- Anchor.

- 200 metres of rope for the anchor.

- 200 metres of mooring rope.

- Cabin alarm system anti-theft or intrusion.

- 50 Anti-Explosion-TK-Safety Jerry Cans x 20 litres=1,000 litres per vessel.

- Manual fuel Pumping System

- Automatic Pumping System

- 20-30 metres of fuel piping for inter-vessel refuel

- Fuel meter included in pump system.

- Extendible “Vessel Aileron Extendible Vessel Inter-Connection Technology”(TK-Patented).

TRANSPORT OF VESSEL

- Plastic and net protection for the transport.

- Metalic bed for the boat (you can use at your base).

TECHNOKONTROL ADDITIONAL SERVICES

Technokontrol offers a five year product guarantee on all of its products ans services and also insurance coverage by AXA Group to cover any incidents with our products, services or technologies which could occur under our responsability and covering only our products and not usage or accidental damages or similar of any type or manner.

We will install, deliver, train all staff members of each vessel and also train staff for maintenance/repair programs via TK-Global Engineering & TK-Global Electronics.

Due to offering the best client service we offer to our clients a personal direct telephone, fax, email, conference line "24/7 Client Emergency Call Centre" to assist any technical or emergency issues and also to arrange any possible sending or spares, repairs, maintenance programs, technical, training assistance, etc.

- 1.- Technokontrol Global Engineering. (ENGINES)

- 2.- Technokontrol Global Electronics. (DAY-NIGHT-THERMAL VISION / RECORDING / RADAR / TELECOM TECHNOLOGIES)

- 3.- Technokontrol Emergency 24/7 Call Center. (CLIENT SERVICES)

Chemical accidents, sabotage & terrorist actions against strategic national industrial, commercial, economic and transport systems.

An Anti-chemical fire fighting/chemical protection machine is seen at the site of a chemical freight train explosion trying to dispurse atmospheric chemicals which may reach the general population or even injure, kill, fire fighters, civil protection , health & safety operators, investigators, law enforcemnet operatives an and ground-aerial emergency services, etc.

These safety & security anti-chemical contamination systems can be used, transported, installed in all types of our Technokontrol vessels, transports, safety platforms involving petro-chemical plants, storage facilities, refineries, chemical production plants, pipelines, rail freight, ports, harbors, etc.

Chemical transports can not only be used for normal industrial & commercial use but also used for an easy, effective way for sabotage, terrorist, anti-system attacks in any nation at global level as chemicals accidents or incidents can be easily made into chemical explosives7explosions with the simple derailment of a train, road tanker, saboatge of port chemical refueling/discharge facilities, internal plant fires, emergency operational system closures, etc.

Worst of all of atmospheric chemical sabotage, terrorist attacks which can be covered as operational accidents but really have political, strategic social, media and economic intentions to effective whole transport networks and closing, evacuating town, cities, general population.

These accidents have already occured three times in the last year in Belgium where we all believe that safety and security are always of the highest european levels but as one can see these accidents or attacks can happen to any nation, operator, anywhere and at anytime globally, thus prevention, security and safety using Technokontrol technologies is and always will be paramount at all levels, especially at government, transport,law enforcement,civil protection, health & safety levels for any nation regardless of its global location.

Video Presentation

- Military Maritime

- Security Test (SPA) - Prueba de Seguridad

- Heat Conductivity of TK Alloys - Conductividad térmica de malla TK

- Types of TK Alloy Formats - Formatos de presentación de malla TK

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Videos

- TK King Shark I & II

- King Shark (5 x 250bhp= 1.250bhp) Mercury Powerboat Engines

- King Killer Whale/King Shark (8 x 250bhp=2.000bhp) Yamaha Powerboat Engines

- Security Test (SPA) - Prueba de Seguridad

- Heat Conductivity of TK Alloys - Conductividad térmica de malla TK

- Types of TK Alloy Formats - Formatos de presentación de malla TK

Ships Collissions

- Luxury Yacht catches Fire

- Explosion on a tanker ship

- MISC ship explosion at Petronas methanol Labuan

- MT Prem Dyvia explosion

- Destroyed in seconds-oil tanker explosion

- Oil tanker explosion during loading

- Bunga Alpinia on fire

- Kapal Tanker Bunga Alpinia MISC Meletup/Terbakar Di Labuan

- MT Bunga Alpinia Fire

- Ship Fire Fighting

- Ship Fire

- MV Stolt Valor

- Chemical Tanker Explosion

- Ship Hits Bridge

- Emma Maersk on Fire - World's Largest Container Ship

- Collision at Sea

- Gibraltar storm causes ship collision - Part I

- Gibraltar storm causes ship collision - Part II

- Ship collision: "Grand Rodosi" crushes "Apollo S"

- Crash of two big ships inside the sea

- Container ship collision during manoeuvre in port

- Collision 2 sea ships on river crossing in Holland

- Ship sinks after collision

For an unmanned ladder version, please go to King Shark XIII - Unmmaned Ladder Version

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

World Vessel Traffic Services Guidelines

- Worldvtsguide.org

- IALA. International Assosciation of Marine Aids to Navigation and Lighthouse Authorities

- Sattelite communications services

- Ship/Vessels Global Insurance Policies

Port authorities manuals & operational guidelines

- IALA VTS Manual

- Guidelines for the Accreditation of VTS Institutes

- Designing and Implementing Simulation in VTS Training

- The Assesment of Training Requirements

- Vessel Traffic Services Operator Basic Training

- The Aspects of the Training of VTS Personnel Relevant to the Introduction of Automatic Identification System

- Basic Training

- VTS Supervisor

- On-the-Job Training - VTS Operator - VTS Supervisor

- On-the-Job Training - Instructor

- Recommendation on Standards for Training and Certification of VTS Personnel

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects