Helipads/Heliports

TechnoKontrol Helipads

TECHNOKONTROL HELIPADS & HELIPORTS is a sector of Technokontrol Technologies specialized in safety, security, efficiency, environmental technologies in all petroleum, technology based sectors and also in the design, construction, installation of surface heliports, rooftop helipads, offshore helidecks, and private airports.

Technokontrol Helipads provides complete 'key in hand-full operations' consultancy, engineering, and equipment services in compliance with CAA and FAA/EASA Airport and Heliport guidelines.

We offer an extensive track record and expertise in developing the finest landing platforms.

- Surface Heliports - Day or Night compliance. - Law Enforcement Heliports.

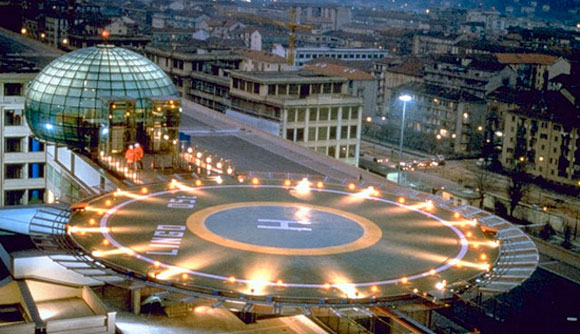

- Rooftop Helipads - Corporate, Hospital Medi-vac. - Military Helipads.

- Off-shore, up/down stream Helidecks - Ship boarding, Offshore Oil Rigs, Off-Shore Platforms. - King Shark/King Killer Whale Vessels Helicopter Carriers Units.

- Private Airports - Day or Night compliance. - ELZ(Emergency Landing Zones). - OLZ(Operational Landing Zones). - ELLZ(Emergency Logistical Landing Zones).

- MLZ(Mobile Landing Zones).

Technokontrol Helipads & Heliports services cover Design, Planning, Engineering, Project Management, Operations, Government Clearances.

The company also supplies essential supporting equipment including lighting systems, fire suppression, navigation and communication aids, wind indicators, safety net, slope indicators and hangars.

Technokontrol Technologies also being a global market leader in safety, security and efficiency technologies has the great advantage of designing our "Helipads and Heliports" at the highest European Union, UK Health & Safety Platform related Directives within the design, manufacturing and installation of additional but now becoming mandatory "Health & Safety Regulations" in these industrial, exploration, extraction, petro-chemical, industrial, logistical sectors and industries.

Any type of off-shore platform related accidents or incidents may occur as being caused by gas, fumes, toxic vapors, fire related incidents where these platform´s "Emergency Exits-Helipads" may be put into danger for the immediate aerial, naval evacuation or emergency use, due to these before mentioned issues but also due to platform climatic damage(storms, hurricanes, tsunamis, etc), accidents, fires, gas, petrol-chemical leaks, ignition and hot points, platform malfunction, platform or drilling ignited explosions, sabotage, terrorist & piracy attacks, etc.

HELI-TECHNOKONTROL Platform Safety Recommendations

We have firm evidence that protecting a platform can save lives making it a secure "Emergency Exit Route", however, we have discovered that during the platform operational use there can be a slow but continues accumulation of mainly flammable, petro-chemical fumes or vapors which in many cases are slowly located, stored in many different platform areas or sections. Due to these gases or vapors being accidentally introduced, spread, stored, located due to operational leakages especially in and around the "platforms bases, legs, internal rooms, sectors, pipelines, operational servicing areas, etc" thus with a simple and accidental "spark" these gases/vapors are then ignited thus causing an explosion or platform fire as has happened in many occasions including storm electrostatic charges-lighting can ignite these gases with a platform even human made electrostatic strike/spark/ignition at any time.

Thus the use of Technokontrol products and services not only being used in the "helipads or heliports" but also in many other areas of the "platform Safety" to assure the highest of Health & Safety levels" for the benefit of the employees safety but also to the "operators", due to also avoiding accidents, environmental damage, loss of revenue, and worst of all extremely high financial compensation packages, as happening in the BP Mexico Sea platform accident where the cost of the damages runs now into the billions of USD without taking into account the time required to return to pre-accident environmental levels and also the "blackout" of BP trying to obtain future operational licenses in the USA and without forgetting the "media backlash" which only can damage the corporations image, good governance and future credibility in all sectors but especially in "Health & Safety".

Please view this link:

Technokontrol Helipads & Heliports, provides an unique "key in hand" solutions in Design, Planning, Engineering, Project Management, Operations, Government Clearances, and Equipment.

Site surveys

Our technical representative checks the topography, conditions on the ground, proximity of obstacles, operational and technical features, to provide an initial assessment of the location.

Feasibility studies

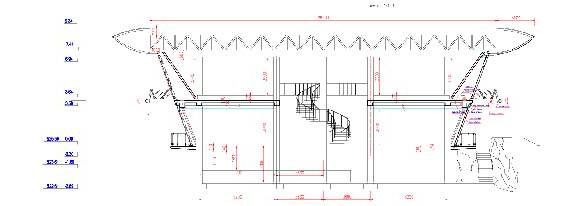

Feasibility study is the first step in initializing a project. The site survey is followed by a preliminary report - which details the findings of the visit and outlines the design requirements and recommendations for completion of project. At a later stage and on the basis of analysis made, a technical report - is prepared which covers every aspect of the project: i.e. Heliport Design, Landing Platform Characteristics, Obstacle Clearance and Limitations, Approach and Take off paths, Load Calculations, Civil Work and Engineering, Equipment, etc…

Obstacle Survey

This is an important phase in implementing a project since it is required by CAA for site approval. We survey the distance and heights of all obstacles likely to interfere with the heliport/airport. It includes survey of approach and take off path - supply of survey technical report - supply of survey aeronautical charts - supply of approach and take off aeronautical charts with approach and climb surface funnels and cross sections. Our survey team needs 15 days notice to schedule your survey.

Design

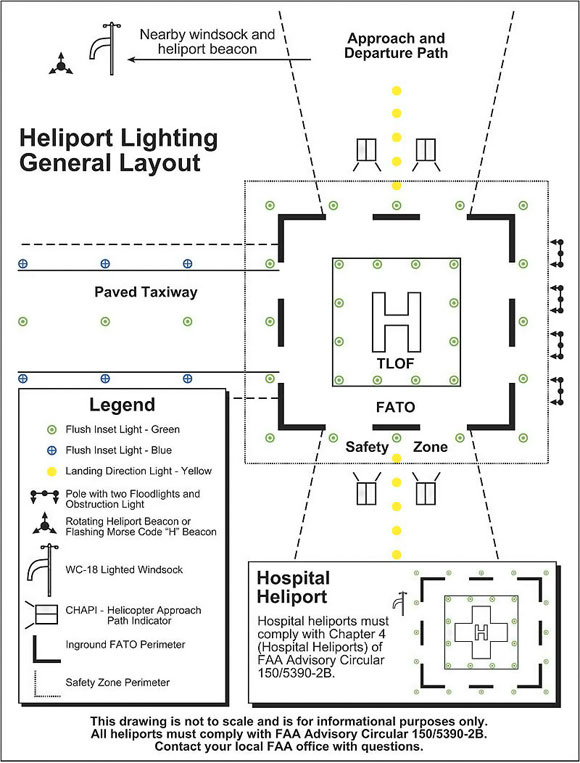

Our heliport designs are CAA and EASA/FAA compliant. For each performance class helicopter the size of FATO, TLOF, and Safety Area are calculated. Similarly obstacle removal and limitations around the heliport are defined. Approach and take off path follow slope and divergence guide lines given for VMC or IMC conditions. On completion of our technical report a complete set of drawings is supplied to our clients.

Project Management

We have experience in both "turn key and project supervision". If you have the capability to undertake some of the work we can also adapt our services to the areas required by you, and help you supervise your project in order to meet the deadline.

Equipment

- Lighting

- Landing Dolly

- Fuel / Water Separator

- Fire Netting

- Wind Cones

- Anti-Thermal & Anti Fire “Panic Rooms”

- Anti–Thermal Helideck base and Anti-Fire Helidecks base and Structure Protection.

Government approvals

Government clearance plays a crucial role in operating a heliports,/Heliports. NOC’s are required from different departments ( MOD, EASA, CAA, FAA, depending on nation regulations, etc) and we act on your behalf to obtain all clearances from site approval to license application.

Operations Manual

Every heliport requires an Operation Manual for licensing. It describes heliport physical characteristics, identification, facilities, and recommended practices. Special operating procedures specify recommended approach and take off path according to wind data and terrain in the vicinity of the heliport.

Engineering

We provide the civil work and engineering of your landing platform i.e. design, construction, assembly, equipment installation, etc… If you have the capability to undertake some of the work we supply the required manufacture design and thus help you reduce the costs.

Equipment > Technokontrol-Technoled LED Lights

- Perimeter Lights

- Beacons

- Flush Lights

- Pilot Lighting

- Flood Lights

- Obstruction Lights

- Windcones

- Lighting Package

Technokontrol-Technoled LED lights

The world's leading Heliport company now offers the best LED light on the market at the best price. Perimeter lights (shown) and obstruction lights are available in ground or pole mount styles.

LED LIGHTING SPECS

- Surface mounted height: 7 1/4"

- Pole mounted thread: 1" NPT

- Surface mounted diameter: (3) 5/16" holes on 5 1/4" bolt circle

- Lamp: 50,000 hour

- Power: 120/230 VAC

- Frequency: 50/60 Hrz

- 0.14 amps @ 120V

- Finish: Yellow powder

- Lens: High tempered glass

- Surface mounted height: 7 1/4"

PERIMETER LIGHTS

The TK-Helipads perimeter lights are an economical way to mark your helipads perimeter. Proven, tested design is ideal for remote locations and help the pilots safely land in all weather conditions.

Weatherproof and virtually maintenance free, FEC heliports perimeter lights can be surface mounted or used with one inch conduit.

LIGHTING SPECS

- Surface mounted height: 7 1/4"

- Surface mounted diameter : (3) 5/16" holes on 5 1/4" bolt

- Pole mounted thread: 1" NPT

- Lamp: 8000 hour, 69 watt

- Power: 120 VAC or other

- Finish: Yellow powder coat

- Lens: High tempered glass

LIGHTING FEATURES

- FAA approved magnifying lens

- Completely wired

- Bulb included

- Easy bulb replacement

- Years of no maintenance

BEACONS

TK-Heliports designs, manufactures and installs a variety of Beacon lighting options. High powered 500 watt identification beacons, with our unique adjustable flash rate, provide long range visibility, even in heavily lighted areas.

TK-Heliports three color beacon are designed to simulate the traditional rotating beacon but with no moving parts. This means less cost and longer life for the customer.

BEACONS LIGHTING SPECS

- Lens: High Tempered Glass

- Finish: Powder Coated Yellow

- Power: 120 VAC or other

- Lamp: 500 Watt Halogen

- Flash Rate: Adjustable

- Housing: Cast Aluminum

- Pulsing Circuit: Solid State

BEACONS FEATURES

- FAA Approved Lens

- Completely wired

- Bulbs included

- No moving parts

- Excellent Long Range visibility

- Easy to install

FLUSHLIGHTS

Low Level Omnidirectional Lighting, Safe to Drive Over, Only 1 1/2" above surface, Double Gasketed Weather Tight, Easy Installation, Available in Amber or Aviation Green Mount in concrete, dirt or aluminum.

FLUSHLIGHTS LIGHT FEATURE SPECS

- Housing: cast aluminum

- Guard: cast aluminum

- Lens: high tempered

- Glass Lamp: 2,000 hr., 60-75 watt

- Power: 120 VAC or other

- Top Flange: 8 inches

- Base Diameter: 4 1/8 inches

- Depth: 4 13/16 inches

- Weight: 9 pounds

- Finish: Yellow Powder Coat

MOUNTING CAN SPACES

- Housing: PVC

- Base diameter: 7 1/4"

- Top Flange 10"

- Depth: 6”

PILOT CONTROLLED LIGHTING

By installing pilot control LED lighting at your heliport, any inbound pilot can activate the lighting equipment by simply keying his microphone on the proper VHF frequency. With the FAA approved controller, a second and third circuit may also be activated to control intensity, additional lights, or other equipment. Frequency selections available.

CONTROLS HELIPORT LIGHTING FROM HELICOPTER

- Maximum utilization of lighting equipment

- Saves electricity, bulbs and maintenance costs

- Unattended all-weather operation

- Simple installation

SPECIFICATIONS

- INPUT: 120 VAC+20%, 50-60 HZ

- OUTPUT: 5 amp relay contact

- SIZE: 10" W x 12" H x 5" D

- MOUNTING: Any flat surface

- WEIGHT: Approximately 15 lbs.

- TEMPERATURE: -55 C to +55 C

- FREQUENCY: 118-133 mhz (as specified by customer)

- ANTENNA: VHF whip or remote available.

FLOODLIGHTS

Heavy-duty, hooded surface floodlight illuminates the deck and protects the pilot from glare while landing on the pad. Fixture is housed in a weather tight, aluminum casting and is powder coated yellow for high visibility.

There are four tabs for easy installation on any surface. Lamps are 90 watt, outdoor rated halogen floodlights, for easy and inexpensive replacement

FLOODLIGHT SPECS

- Housing: Cast Aluminum

- Lens: High Tempered Glass

- Lamps: 90 watt, outdoor rated

- Finish: Yellow powder coated

- Power: 120 VAC, or other

FLOODLIGHT DIMENSIONS

- Height: 6"

- Width: 12 1/4" (@ hood 15 1/4")

- Depth: 5 1/4" (+ hood 9 1/2")

- Bolt Spacing: 4 1/2" and 14"

- Bearm Spread: 1000

OBSTRUCTION LIGHTS

The TK-Helipads Obstruction Lights are an economical way to mark the heliport perimeter and surrounding obstructions. Proven, tested design is ideal for remote locations.

Weatherproof and virtually maintenance free, models can be surface mounted or used with one inch piping.

OBSTRUCTION LIGHTING SPECS

- Surface mounted height : 7 1/4"

- Surface mounted diameter : (3) 5/16" holes on 5 1/4" bolt circle

- Pole mounted thread: 1" NPT

- Lamp: 8000 hour, 69 watt

- Power: 120 VAC or other

- Finish: Yellow powder coat

- Lens: High tempered glass

OBSTRUCTION LIGHTING FEATURES

- FAA approved magnifying lens

- Completely wired

- Bulb included

- Easy bulb replacement

- Easy bulb replacement

WINDCONES

The TK- Wind cone is designed to meet the requirements of AC 150/5345-27C. It is made of aluminum, not steel, allowing it to last much longer. The wind cone has a hinged base to change lights easily. All of the TK- Wind cone components are powder coated in orange for long-lasting protection against severe weather. Our wind cone is designed to easily install on the roof, ground or wall.

WINDCONES SPECS

- Height: 10'

- Power: 120 VAC or other

- Base: (4) 3/4" holes on 7" bolt circle

- Weight: 42 lbs.

- Basket Diameter: 18"

- Basket Length: 24"

- Finish:Int'l orange powder coat

- Lens: High tempered glass

- Floodlights: (4) 2000 hour, 50 watt

- Obstruction Light: 8000 hour, 69 watt

Bright orange, highly visible, replacement windsocks for safer landings. All styles furnished with #2 spur grommets for maximum strength. Throat and tails are double stitched and designed to fully extend with a 15 mph wind. All sizes available from 8" x 36" to 48"x 144".

LANDING SERIES ALUMINUM EXTRUSION

LARGEST LANDING AREA OF ANY OTHER DOLLY ON THE MARKET

- Quick and Easy Assembly (2 straight pin to connect and you're done)

- High - durability wood surface (aluminum optional)

- High - visibility orange finish

- Low profile - only 16" off ground

- Durable 10" solid flex rubber wheels for softer landings (air filled wheels also available)

- (2) Sizes Available

- 14' x 16' for all helicopters up to 9,500 lbs

- 14' x 20' for all helicopters up to 15,000 lbs

FUEL/WATER SEPARATORS

Our standard Fuel/Water Separator is a gravity operated unit fed from the gutter system attached to the heliport. The welded steel separator has an adjustable oil draw-off, and an integral baffle system.

It has a 3/8" nonskid diamond tread plate cover for pedestrian traffic (or reinforced for light/heavy traffic) secured by stainless steel bolts and an extra heavy leak proof gasket. The shop coating helps protect the separator from outside elements and is resistant to oil, grease and cutting oils.

- Static Holding Capacity: 400 gallons

- Integral Storage: 300 gallons

- Total Capacity: 700 gallons

- Inlet: Flanged 6"

- Outlet: Flanged 6"

- Vents: Tapped 4" I.P.S.

- Material: 10ga. A36 steel

- Design Weight: 7,300 lbs.

- Ship Weight: 1,200 lbs.

- Coating Inside: Opex shop coating

- Coating Outside: Bituminous coating

- Tank Heater: 5000W, 240V or 208V Only, Single phase

- High Level Indicator: 120V

Fire Fighting

Fire Suppression: HELI-TECHNOKONTROL designs and installs a variety of AFFF foam fire suppression equipment to meet your facilities needs. We also supply equipment for H-1 and H-2 category helipads.

Fire Fighting Requirements For Elevated Heliports

6.1.4.The principal extinguishing agent shall be a foam meeting the minimum performance

level B.

6.1.5.The amounts of water for foam production and the complementary agents to be provided shall be in accordance with the heliport fire fighting category determined under 6.1.1 and Table 6-2 or Table 6-3 as appropriate.

Note : The amounts of water specified for elevated heliports do not have to be stored on or adjacent to the heliport if there is a suitable adjacent pressurized water main system capable of sustaining the required discharge rate.

6.1.6. The discharge rate of the foam solution shall not be less than the rates shown in Table 6-2 or Table 6-3 as appropriate. The discharge rate of complementary agents shall be selected for optimum effectiveness of the agent used.

6.1.7. At an elevated heliport, at least one house spray line capable of delivering foam in a jet spray pattern at 250 L/min shall be provided. Each having a capability of achieving the required discharge rate and positioned at different locations around the heliports so as to ensure the application of foam to any part of heliport under any weather condition and to minimize the possibility of both monitors being impaired by a helicopter accident.

Table 6 - 1 - Heliport Fire Fighting Category

|

Category |

Helicopter over - all Length a |

|

H1 |

up to but not including 15m |

|

H2 |

From 15 m to but not including 24 m |

|

H3 |

From 24 m up to but not including 35 m |

Table 6 -3 - Minimum usable amounts of extinguishing agents for elevated heliports

|

Foam meeting performance Level B |

Complementary agents |

||||

|

Category |

Water (l ) |

Discharge rate foam solution(L/min) |

Dry chemical powders (kg) |

Halons (kg) |

CO2 |

|

(1) |

(2) |

(3) |

(4) |

(5) |

(6) |

|

H1 |

2 500 |

250 |

45 |

45 |

90 |

|

H2 |

5 000 |

500 |

45 |

45 |

90 |

|

H3 |

8 000 |

800 |

45 |

45 |

90 |

6.1.8 - At an elevated heliport rescue equipment shall be stored adjacent to the heliport.

6.1.10 - At an elevated heliport, the rescue and fire fighting service shall be immediately available on or in the vicinity of the heliport while helicopter movements are taking place.

6.6.4 - The discharge rate of the foam solution should not be less than the rates shown in Table 6-2 or 6-3 . The discharge rate given in these tables is the rate required to obtain a one - minute control time over the critical area. It is determined for each heliport RFF category by multiplying the critical area by the application rate.

6.6.5 - To permit helicopter occupants either to evacuate or be rescued, the amounts of water to be provided are based on the assumption of a fire attack lasting approximately 2 minutes at a surface level heliport and 10 minutes at an elevated heliport.

6.6.6 - The Purpose of the extended fire attack period for an elevated heliport is to permit protection of the entire helipad from the effects of fire in order to protect the very limited routes of escape. In the case of an elevated heliport it is also considered essential to ensure that the agents can be applied to the entire helipad irrespective of the wind direction.

Table 6-4 Calculation of Critical area and amounts of water needed for foam production

|

Helicopter Fire Fighting Category |

|||

|

H1 |

H2 |

H3 |

|

|

Determination of Critical Area |

|||

|

Overall Helicopter Length |

|||

|

Lower Limit(m) |

0 |

15 |

24 |

|

Upper limit |

≤15 |

≤ 24 |

≤ 35 |

|

Average helicopter fuselage length(m) |

8.5 |

14.5 |

17 |

|

Average helicopter fuselage width(m) |

1.5 |

2 |

2.5 |

|

Additional width factor W1(m) |

4 |

4 |

6 |

|

Critical Area(m2) |

47 |

87 |

144 |

|

Application rate(L/min/M2) |

5.5 |

5.5 |

5.5 |

|

Discharge rate-foam solution(l/min) |

250 |

500 |

800 |

|

Water Needed for Foam Production |

|||

|

Surface-level heliport(L) |

500 |

1000 |

1600 |

|

Elevated heliport(L) |

2500 |

5000 |

8000 |

NOTE: Helicopter category H2

6.8 Special provisions related to elevated Heliports

6.8.1 - Particular problems arise from the operation of helicopters at elevated heliports that require special attention with regard to the rescue and fire fighting provisions. One important aspect is the confined and restricted space available on the average elevated heliport.

This will impose restrictions on foam monitor positioning and general fire fighting tactics. It is feasible that an accident could result in a fuel spill and a fire situation that could quickly cut off or reduce the already limited routes of escape to a place of safety for the occupants of the helicopter. In addition, the accident or fire may involve rescue and fire fighting facilities located adjacent to the elevated heliport.

As a result the requirement for the amounts of extinguishing agents at elevated heliports is based on a fire fighting service should be immediately available on or in the vicinity of the heliport while helicopter movements are taking place.

6.8.2 - At an elevated heliport, at least one hose spray line capable of delivering foam in a jet spray pattern at 250 L/min should be provided. This calls for the provision at a heliport category H1 of a hose line equipped with a nozzle capable of discharging foam/water in a straight stream (jet) and/or a dispersed pattern (fog/spray).

6.8.3 -It is also considered essential at an elevated heliport to be able to apply the fire fighting agents, both principal and complementary, to any part of heliport irrespective of the wind direction. To achieve this and to overcome the possibility of a monitor being involved in the accident, it is necessary that at elevated heliports in category 2 and 3, at least two monitors be provided each having a capability of achieving the required discharge rate, and positioned at different locations around the heliport so as to ensure the application of foam to any part of the heliport under any weather condition. To further ensure the application of the agents to any part of the heliport under any weather condition, the monitors should preferably be operable from two remote control positions located clear of the heliport and easily accessible.

SAFETY NETTING

TK-HELIPADS/HELIPORTS standard design is made from structural tubing and 1" 9-gauge fencing. Our safety netting is designed to meet or exceed the FAA criteria of 250 pounds applied over any one square foot or 25 psf overall. The safety netting protrudes out 5 feet from the edge of the deck (6 feet in the state of California) but does not rise above the helistop surface.

All components are powder coated or galvanized for maximum protection in all weather conditions.

All TK-HELIPADS safety nettings are designed via a exclusive and unique build process. We can meet any aesthetic desires that you may have.

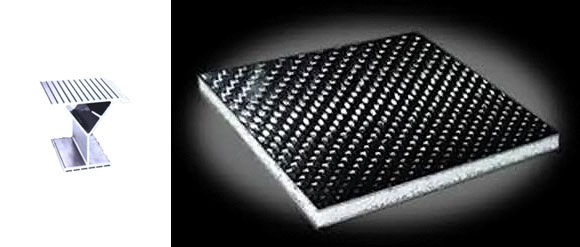

TK-HELIPAD ALUMINIUM

The TK-HELIPAD ALUMINUIM is a pre-engineered aluminum design. Engineered and manufactured by our partner Technokontrol Engineering. It can be extruded up to 60 feet in length. This tongue and groove design, when properly supported, is capable of handling in excess of 25,000 pounds of gross weight.

The TK-HELIPAD ALUMINUM can be designed to meet any helipad size requirements. It has an integrated non-slip surface and is coated with an additional non-slip paint to provide protection in all weather. We have designed the TK-HELIPAD ALUMINIUM with an internal snow melting cavity to accommodate either a glycol snow melting system or electrical heat cable. This unique design provides superior heat transfer in the harshest snow environments.

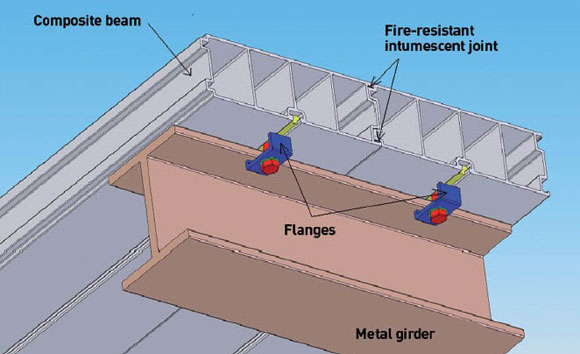

The TK-HELIPAD ALUMINUM is attached to steel or aluminum I-beams and utilizes a TK-Engineering designed clamping device to reduce installation time. TK-Engineering also provides a neoprene isolation system between the steel and aluminum for dissimilar metal isolation and to help reduce vibration.

TK HELIPAD COMPOSITE

Advantages of Composite over Concrete and Steel

Lightweight - They can be placed on the roofs of most buildings, including those which are not designed to take major additional loads. They can also be built over new, structurally lightweight buildings. Ground heliports built on columns can be supported by small footings, eliminating the need for deep foundations. When of equal strength, composite material are about one tenth of the weight of concrete.

Attractive - They blend easily with most environment thanks to the variety of shapes, textures, and colors available.

Lifting of a semi-structure

Easy to assemble - The installation of TK-HELIPADS does not require heavy- weight equipment. Structures are prefabricated off-site, and then transported in modules. Final assembly is uncomplicated and fast.

Nominal maintenance requirements - Composite materials require little maintenance, even in corrosive environments or in climates that experience large temperature variations.

Durability - TK-HELIPADS are hydrocarbon resistant. There are manufactured to withstand ultra-violet radiation, physical impacts and strong winds. Schools in Saudi Arabia and public buildings built 25 years ago from composite materials in the extreme north of Canada demonstrate the durability of the product, even in severe climatic conditions.

Composites beams are fitted together

Assembly diagram

EXTREME THERMAL FIRE & HEAT RESISTANT “TK-HELIPADS” built from composite materials are fire and heat resistant, particularly when compared to heliports built from materials such as steel or aluminum.

Our other Extreme “Technokontrol Safety and security panels” can protect against thermal, fire, petroleum fires for over 240 minutes at over 1200ºC-1600ºC, we are the only manufacturer in the World who has such patented and tested safety technology.

The structure of TK-HELIPADS allows for the installation of de-icing systems under the landing surface thereby ensuring safer landings during inclement weather.

Adaptable – TK-HELIPADS/HELIPORTS are adaptable - they fit a variety of load-bearing surfaces. Often, no changes are required to the existing roof and its climate-control equipment during installation.

TK-HELIPADS PRE-ENGINEERED ALUMINIUM DESIGNED.

The TK-HELIPADS are a pre-engineered aluminum Design. Engineered and manufactured by our partners TK-GLOBAL ENGINEERING . It is 1 1/2" thick and 2' wide. The TK-HELIPADS panels can be extruded up to 45 feet in length. This interlocking design is capable of handling in excess of 25,000 pounds, and can be designed to meet any size pad.

Typically the TK-HELIPADS are used for ground based heliports, instead of a traditional concrete pad.

The TK-HELIPADS are a perfect solution for replacing damaged concrete pads. The panels can be placed right over the top of the old helipad. If you facility expands, the TK-Helipads can easily be moved to another location.

“Technokontrol Safety, Security Panels, Structures & Alloys” can protect against thermal, fire, petroleum fires for over 240 minutes at over 1200ºC-1600ºC, we are the only manufacturer in the World who has such patented and tested safety technology.

Advantages over concrete and steel

Maintenance Free

Non-corrosive Aluminum

Permanently Portable

Relocate it

Lightweight

6 PSF

Completely Accessible

Add or Check Snow Melt System

Cost Effective

Long-term Savings in Maintenance and Relocation

TK -MOBILE & FLOATING HELIPADS

The TK-MOBLE HELIPAD & FLOATING HELIPADS from our partner TK-GLOBAL ENGINEERING.

This product can be used for anything from special events to search and rescue.

Made from our TK- MOBILE HELIPADS Aluminum Series, this helipad is a lifetime investment.

Set up our TK-MOBILE HELIPADS and easily disassemble and store it for future use.

- Quick and Easy Setup

- Adjustable legs to accommodate terrain

- Standard sizes of 20' x 20' & 30' x 30'

- Portable stairs, lighting and tie downs optional

- Can be easily disassembled and stored for future use

TK-OFF SHORE HELIPADS/HELIPORTS

The TK-OFF SHORE HELIPAD is a pre-engineered aluminum design engineered and Manufactured by our partners that can be extruded up to 60 feet in length.

This tongue and groove design, when properly supported, is capable of handling in excess of 35,000 pounds of gross weight.

The TK-OFF SHORE HELIPAD can be designed to meet any helipad size requirements.

It has an integrated non-slip surface and is coated with an additional non-slip paint to provide protection in all weather. TK Global Engineering has designed the TK-HELIPAD ALUMINUIM SERIES with an internal snow melting cavity to accommodate either a glycol snow melting system or electrical heat cable.

The TK OFF-SHORE HELIPAD is attached to steel or aluminum I-beams and utilizes a TK-ENGINEERING designed clamping device to reduce installation time.

TK-HELIPADS also provides a neoprene isolation system between the steel and aluminum for dissimilar metal isolation and to help reduce vibration.

Platforms Accidents, Explosions & Fire Images

Video Presentations

- TechnoKontrol Safety Videos

- What is B.L.E.E.V.E.? Explanation

- Fuel explosion examples

- Fuel Barrel Flame Ignition & Welding Test - Prueba de Ignición y Soldadura en un Barril de Combustible

- Pipeline Explosion Test - Prueba Anti-Explosión en Ductos

- Security Test (SPA) - Prueba de Seguridad

- Heat Conductivity of TK Alloys - Conductividad térmica de malla TK

- Fuel Vaporization Test - Prueba de vaporización de combustible

- Types of TK Alloy Formats - Formatos de presentación de malla TK

- Alloy Vaporization Test

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

TK Military Aviation

Maritime, River, Port Protection

TK Military Maritime

Aviation & Airports Protection

Platform Video Explosions & Reports

- BP Gulf Mexico Platform Explosion

- Elgin Gas Leak Video Explanation

- BP Gulf Explosion Full Video Explanation

- BP Gulf Video Corporate Video Explanation

- Gulf of Mexico Platform Explosion

- Live Platform Explosions

- Live Platform Damage Images

- Louisiana Sea Platform Explosion

- How to Prevent Deep Sea Platform Explosions

- Photo-Video of Deep Sea Platform Unique Photos

- North Sea Platform Shut Down due To H&S Explosion Risks

Types of LNG/FLPG Video Explanations

- Floating FLPG/Natural Gas Floating Vessel Platforms

- LNG Super Tanker Video

- LNG Video Summary

- First FLPG Shell Platform Vessel

- Multipurpose LNG Terminal Vessel Operations

- LNG Production Video Explanation

- LNG FPSO Vessel Contractors

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Ships Collissions

- Luxury Yacht catches Fire

- Explosion on a tanker ship

- MISC ship explosion at Petronas methanol Labuan

- MT Prem Dyvia explosion

- Destroyed in seconds-oil tanker explosion

- Oil tanker explosion during loading

- Bunga Alpinia on fire

- Kapal Tanker Bunga Alpinia MISC Meletup/Terbakar Di Labuan

- MT Bunga Alpinia Fire

- Ship Fire Fighting

- Ship Fire

- MV Stolt Valor

- Chemical Tanker Explosion

- Ship Hits Bridge

- Emma Maersk on Fire - World's Largest Container Ship

- Collision at Sea

- Gibraltar storm causes ship collision - Part I

- Gibraltar storm causes ship collision - Part II

- Ship collision: "Grand Rodosi" crushes "Apollo S"

- Crash of two big ships inside the sea

- Container ship collision during manoeuvre in port

- Collision 2 sea ships on river crossing in Holland

- Ship sinks after collision

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects