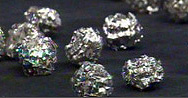

Physical Characteristics

Techno-Kontrol physical characteristics

When Gasoline; Diesel; Gas or any other type of combustible vapour mixes with air and meets a spark a flame or explosion is almost certain to take place. This is called the BLEVE Effect (boiling liquid and an expanding vapour leads to an explosion) and a typical situation of where this can take place is in that of a traffic or aviation accident. In this situation, the accident causes an explosion within the fuel tank due to a huge amount of energy being feed through in a very short space of time.

To prevent this reaction and via the use of our special Techno-Kontrol Alloys, the internal surface of the tank is amplified by 3000% which means that our product with its breakthrough technology can completely stop the explosion from ever taking place.

This reduction is created by the interposition all along the tank's interior of the aluminium/magnesium alloy. The ample surface contact interposes the heat wave, absorbing all of its calorific energy therefore stopping its advance and as explained above, this advance of energy is the normal cause of why explosions take place in the first place.

This is achieved by our TK operators installing our specially designed VI Generation alloy at the semi-final stage of the manufacturing process depending on the products applicatioas or usage.

Also as each country contains a different atmospheric condition (i.e. high or low humidity, altitude, heat/cold etc.) our R&D department has been able to manufacture and adapt our exclusive VI generation alloys so that they can both withstand and be applied in any meteorological condition.

However we advise our customers to always revert back to our safety certificates in which many International laboratories have proven that if a tank is filled to the top with our special Techno-Kontrol Alloy Material that it will prevent explosions from taking place a 100% of the time.

TechnoKontrol Alloy Characteristics

- How it Works

- Physical Characteristics

- Technical Characteristics

- Flammable & Combustible Liquids - Hazards

- What is B.L.E.V.E. Explosion?

- TK-Global Engineering

- TK-Global Electronics

- TK-Global Environment

- TK-Global Technotelecom

- TK-QSSHE

- TK-Financing

- TK-Emergency Call Center

TechnoKontrol product and application videos

- TK Outdoor Tests Presentation - Fire Services / KNPC Kuwait

- Demonstration video

- Liquids balance

- Gas cylinders manufacturation process

- Panel at 1600°C 2 hours

- Wall at 1600°C +2 hours

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

TK-Global Engineering - Where efficiency and reliability become a reality

More info

Should you want to receive more information, please contact us.