Pipelines, Fracking & Pumping Stations Environmental Damage, Security and Safety Issues

Pipelines, Fracking & Pumping Stations Environmental Damage, Security and Safety Issues

Basic Technical of any EU or USA installed pipeline infrastructure.

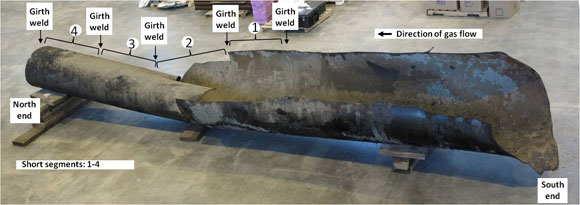

- The most normal pipelines are 24-48 inches(50-100cm) in diameter, 4 feet(1 meter) below the soil surface

- At maximum capacity, they carry 400,000+ barrels per day of NGLs.

- Any route includes land clearing and a permanent easement on either side of the pipeline, typically 50 feet (16 meters).

- Any designated route and installation will include stream crossings, hills, caves usage, tunnels numbering in the hundreds.

- Buildings as pumping stations have to be built and controlled through the pipeline route.

- The risk of criminal, terrorist, accidental incidents are extremely possible and easy to occur as passive or active security or minimum or nil in many cases.

The two most important questions at this point with any pipeline are:

- What are NGLs and what kind of risks are associated with an NGL pipeline?

- Does the pipeline company have the ability to protect the complete pipeline route?

As for the first question, most natural gas extracted from the Earth contains, to varying degrees, low molecular weight hydrocarbon compounds; examples include methane (CH4), ethane (C2H6), propane (C3H8) and butane (C4H10).

Although these hydrocarbons exist in a liquid state at underground pressures, they will become gaseous at normal atmospheric pressure. Collectively, they are called natural gas liquids (NGLs).

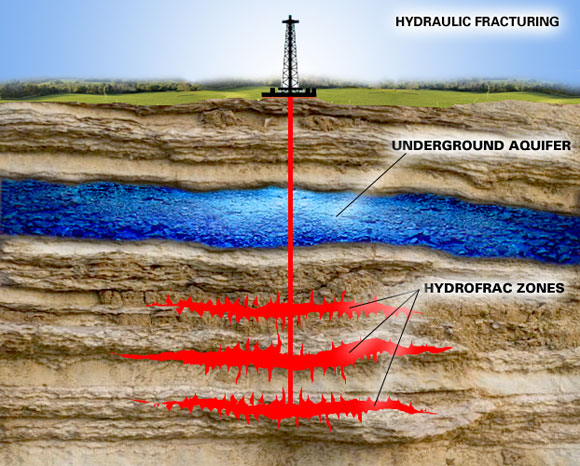

As this document explains, NGL “production” has increased significantly over the past few years, going hand-in-hand with the process of hydraulic fracturing for natural gas.

The most common NGL products or components (ethane, propane, butane, isobutene, and natural gasoline) are broken up, or fractionated, and used as raw materials by the petrochemical industry, as feed stocks by refiners in the production of motor gasoline, and as fuel by industrial and residential users.

The table below, from the U.S. Energy Information Administration, conveys typical NGL constituents and products.

NGLs need to be taken somewhere that they can be separated into their constituents so that they can be used in various ways, and thus need transportation to refineries, processing, industrial plants, etc.

The main risks associated with NGL exposure and NGL pipelines are:

Once a spill occurs, typical petroleum and crude oil are very difficult to sufficiently clean and remove from the environment, and have much longer residence times. However, as mentioned earlier, once NGLS are exposed to normal atmospheric pressure they become gaseous and much more quickly biodegrade. This does not mean, though, that these chemicals are nothing to worry about from a water perspective, or that there are few risks to humans.

NGLs that stay primarily subsurface can certainly leach into groundwater and cause problems for short time frames. When NGLs become gaseous, depending on the concentration of the gas and the atmospheric conditions, the NGLs can cause breathing trouble (irritation of nose and throat, dizziness, drowsiness, euphoria, disorientation, etc); ingestion problems (gas can enter lungs and cause inflammation and damage); and skin (vaporizing liquids can cause frostbite if too close.

More importantly, these liquids are highly flammable-explosive, and guess what–leaks, ruptures, and explosions do happen. This is an extreme concern. But surely, any pipeline can’t locate within a certain distance of a school, or a hospital, or a place of residence Surely there are laws regarding the placement of NGL pipelines, in order to reduce the impacts to people and resources There are certainly various laws that the company will have to follow, and permits that must be acquired, but no laws specifically place restrictions on placement of an NGL pipeline.

In addition, the pipeline requires the installation of pumping/compression stations every so often (between 30-100 miles/50km-150km), to ensure sufficient pressure. These pumping/compression stations typical run day and night on diesel fuels or natural gas, impacting local air quality and creating noise issues.

These pumping/compression stations themselves are a risk of fire and explosions. These pumping/compressor stations mostly just fall under the jurisdiction of local planning and development departments.

As for the second question, one has to know that most petro-chemical corporations do not wish to encounter any kind of civil, legal, PR, environmental issues as people, local and regional governments are willing to claim damages if anything goes badly due to any incident.

However, this doesn´t mean that as in any industry there are operators whom are in the business of short term profits and don´t really care of any of the issues above mentioned thus putting at risk anything and knowing that any fines, legal battles, environmental, legal payments are worth paying on the long run and which are dragged through any legal process through and the court systems for years and years and trying to reach lower payments to work out in their benefit the profits already obtained.

In many cases these companies should plan ahead and see that creating, designing, installing a well operated, secure, safe and the highest environmental project maybe be less expensive than they could imagine and not only investing through those initial funds into the project but also making the whole project safer and allowing any applications being approved easier at local, regional, state level which can only mean a better reputation for future projects as their incident rates will be as low as possible creating a great PR backup and credibility when they apply for future projects as the people, citizens, affected persons will only see good company governance and good will which can only be “earned” and not “bought” regardless of any short cuts they believe they will gain by short profit planning against a long term secure project.

The last point is also the ethical, morale grounds that anyone should stand on and especially knowing of the possible damages of any strategic, dangerous, environmental complex industry as the petro-chemical industry which can so easily go wrong and we believe that one’s personal and professional bases should be applied for oneself and then to the rest and this surely will reduce of any mal practice, quick profit scenarios when really we are only leaving behind what we have invested and sooner or later everything comes back and a greater level and not really being worth it.

Efficiency, productivity, financially viable businesses don´t mean cost cutting, low quality, dangerous risk planning, it means planning ahead, being the best, being proactive at all levels not only for the company sake but also for the security, wellbeing of all residents, business, future generations….

Do we want a region, nation with acid rain as in Lagos; Nigeria Do we want atmospheric pollution which has been recognized by the W.H.O as being “mortal” for our children, families, friends Do we want oil, gas, chemical explosions-fires, vapor, gas exposures killing our wildlife, countryside, water reserves, our environment

We should learn form may other nations whom have already done this especially based and operational in Asian-African markets which we should learn from and we can see their already safety, security and environmental issues.

If one doesn´t plan well ahead, one day from the largest international petro-chemical corporations to any small sized refinery will be put in front of courts and juries as the “Big tobacco’s corporations in the last decades” and they will be sued, fined billions for medical, human costs, loss of earnings, long term illnesses, deaths, environmental damages, thus if they have seen what has happened in other complex industries.

Why not being proactive and avoiding these issues with the best possible security and safety technology from the very start and investing now for their own benefit, for the greater valuation of their company, their shareholders, their corporate governance and not end up paying out massive payouts which won´t also solve any problems as these funds are directed at personal level or government level and to which will be never be re-invested into finding any real term solutions as illnesses, injuries, health issues and/or environmental incidents can´t be put right easily and to which we are lose out when there is already a solution.

Video explosions

- Saudi Arabia Fuel Tanker Explosion

- Fuel Tanker Explosion Aftermath

- Mexico Truck Gas Tanker Explosion

- LP Gas Storage Station

- LP Gas Facility

- China Fuel Tanker Motorway Explosion

- PDVSA Refinery Explosion

- City Block Gas Explosion - South Korea

- Chemical Road Tanker Explosion Motorway

- Fuel Tanker Explosion Saudi Arabia

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Documentation

- E.U. Strategic Fuel Reserves Directives 2012

- E.U. Strategic Fuel Reserves Directives 2006

- Protección de Infraestructuras Estratégicas y Críticas en la U.E. (SPA)

- Institute of Petroleum - Guidelines for Soil, Groundwater and Surface Water Protection & Vapours Emissions

- Ley de Hidrocarburos y de Seguridad Nacional de Abastecimiento (SPA)

- Protección de Refinerías (SPA)

- Almacenamiento Inflamables Combustibes (SPA)

- Almacenamiento Productos Químicos (SPA)

- Directiva del Parlamento Europeo y del Consejo 94/9/CE, relativo a los aparatos y sistemas de protección para uso en atmósferas potencialmente explosivas (SPA)

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects