TK-PSAXSS Petrol Station Anti-Explosion Safety System

TK-PSAXSS TechnoKontrol-Petrol Station Anti-Explosion Safety System

As there are millions of explosions every year within our Towns and Cities, the Technokontrol´s Research & Development team has designed a new VI Generation patented product in which via utilizing our new safety technology our TK-PSAXSS can prevent any fuel discharge explosion from occurring within a petroleum depot´s environment. These explosions normally are initiated by the concentration of gas, heat, fuel-gas leaks, sparks and / or electrostatic discharges.

The risk of discharging fuels at petrol stations

We have all heard that underground fuel deposits do not explode under any circumstances but our scientists can assure you that no matter how small the risk, fuel deposits can explode with some explosions creating the same damage as that of a semi-nuclear explosion.

Therefore petrol stations are areas where explosive atmospheres can be present even under normal operating conditions. The reason for this is that petrol or gas fumes are heavier than air and when a customer refuels their vehicle with petrol or gas, fumes can be leaked. These fumes are invisible to the naked eye and when leaked they will drift downwards (due to their weight) or they can also be pushed upwards from underground tanks due to overpressure and when mixed with air can form a very dangerous explosive atmosphere. Thus one single spark or electrostatic charge can make these fumes turn into a fireball explosion.

To alleviate this risk factor or possibility of an explosion, a petrol station can use our specially designed alloy which is 100% anti explosive. Our product is not only non combustible and easy to maintain, but as is already used within many different chemical safety applications under EU Safety Directives.

What is TK-PSAXSS?

It is a unique system which enables the petrol-chemical industry to avoid the possibility of any explosions taking place within their fuel deposit communications infrastructure and studies show that it is both cost effective and easy to incorporate into any corporations existing operations budget.

The TK-PSAXSS System will enable any Petrol Station or Depot to operate safely and to naturally discharge their fuels with total security that no explosion will occur as any fumes leaked will not be diffused and therefore will not be able to ignite.

Other Benefits of TK-PSAXSS

- It is easy to adapt/modify so as to attach onto any existing maintenance hole cover (if required)

- It contains a unique anti theft system which does not interfere with the entrance or exit of authorized personnel.(optional)

- It is 100% transferable and reusable

- It is 100% eco-friendly and 100% recyclable

- It is easy to clean and maintain

TK-PSAXSS- How to apply the safety system?

In order for our TK-PSAXSS system to 100% protect against a petrol station or depot from exploding, the entire volume of the respective chamber or chamber shafts must be entirely protected with our safety technology. Once protected, the possibility of an explosion occurring within one of these spaces is non-existent.

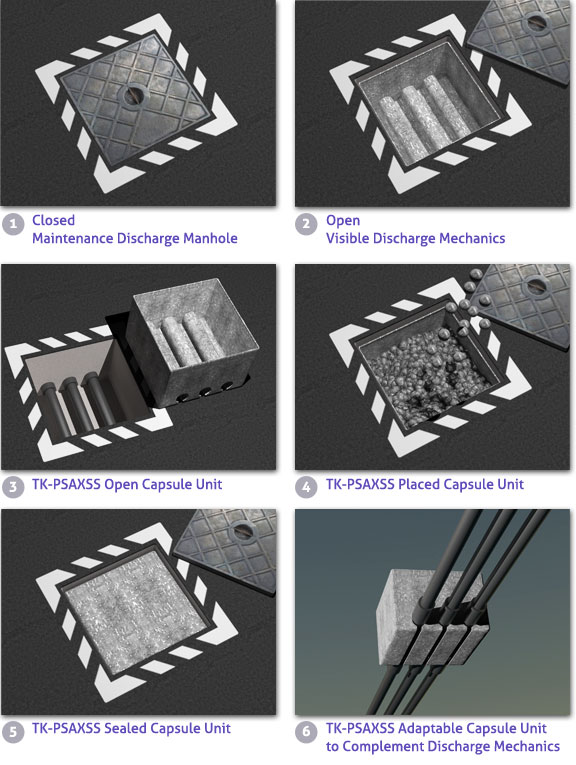

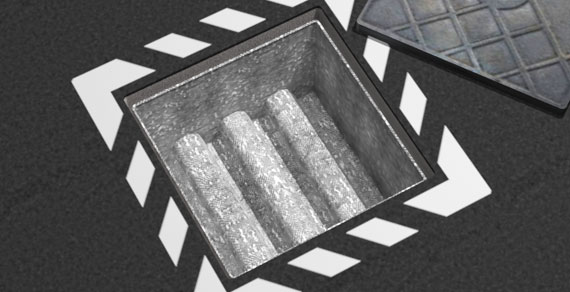

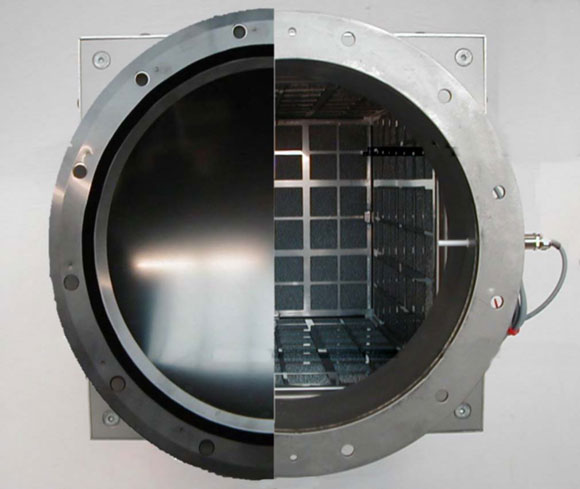

TK-PSAXX Diagram

In addition to this, we recommend that at the time of installing TK-PSAXSS that the respective petrol station or depot incorporates into their operations budget the installation of our Technokontrol Valve System. These systems will not only further increase the safety of the petrol stations tanks, but they will also provide the client with an increase in fuel discharged (i.e. reduce the time needed to unload the product) by up to 40%. These savings will enable our clients to recover the cost of installing both the TK-Fuel Valve System and our TK-PSAXSS safety systems.

Installation of TK-PSAXSS

As with any business, if a particular section of a business is closed for any length of time, it can become extremely costly. For both the operator and owner if an explosion takes place they will have to deal with two costs, the first and more important cost is that of the loss of life or social costs and the second costs are those of an indirect nature such as closing down the business, loss of earnings, legal action, investigations, rebuilding etc. However, as TK-PSAXSS takes away the threat of any explosion occurring, all the above costs are automatically eliminated.

The installation process is extremely quick. Once we have the details of the discharge unit, size, capacity and design we will produce a suitable unit to be installed. We always recommend that our clients conduct a pre-order inspection so as to ensure the correct details are obtained and thus enabling any changes to be dealt with at a pre-manufacturing stage.

TK-PSAXSS Discharge unit example

Once the above details are established and confirmed the manufacturing process will begin. After which as the units are pre- constructed to meet every client´s individual needs the TK-PSAXSS can be installed with minimal disruption or closure of the tanks taking place.

Technokontrol International Safety & Quality Standards

As Technokontrol operates all of its facilities (i.e. research, development and manufacturing) within the European Union we can ensure that our clients will receive a finished product which meets (if not surpasses) the highest possible International Accident, Health & Safety Standards.

Standards such as

- US NFPA-69-2008-Standards on Explosion preventing Systems

- UK- SI 1982/630 Petroleum spirit for use in both motor vehicles & plastic containers.

- EU- ADR Directive 1999/36CE

- ISO 9000, ISO14000, ISO18000, 1SO23000 (2012)

- CE Certified Manufacturer.(2012)

Maintenance

As our TK-PSAXSS System is made by means of a new VI generation alloy mesh it is both easy to clean and to maintain however most importantly our mesh is both 100% eco-friendly and recyclable.

Studies show that our TK-PSAXSS system is both a cost effective and efficient system and therefore any operator can easily incorporate it into their operation program.

Because our TK-PSAXSS system comes with a low level maintenance system it can be lifted, cleaned (by hand or by compressed air) and replaced within 5 minutes.

Video Presentations

- TechnoKontrol Safety Videos

- What is B.L.E.E.V.E.? Explanation

- Fuel explosion examples

- Fuel Barrel Flame Ignition & Welding Test - Prueba de Ignición y Soldadura en un Barril de Combustible

- Pipeline Explosion Test - Prueba Anti-Explosión en Ductos

- Security Test (SPA) - Prueba de Seguridad

- Heat Conductivity of TK Alloys - Conductividad térmica de malla TK

- Fuel Vaporization Test - Prueba de vaporización de combustible

- Types of TK Alloy Formats - Formatos de presentación de malla TK

- Alloy Vaporization Test

ATEX - European Antiexplosive Safety Directives

PREPARATION/DEGASIFICATION OF A PETROL STATION FUEL TANK, FUEL TANKERS, STORAGE FACILITIES BEFORE ATEX/NFPA: TK-ANTI-EXPLOSION ALLOYS INSTALLATION

ATEX/NFPA SAFETY DIRECTIVES FOR ATMOSPHERIC GAS/PETROL-CHEMICAL RISK-EXPLOSION ZONES

ATEX/NFPA EXTREME DANGER-DISCHARGING OF EXPLOSIVE GASES/VAPOURS AT PETROL STATIONS, MANHOLES, STORAGE TANKS

IMAGE OF AN ATEX/NFPA PETROL STATION MANHOLE REFUELING POINT WITHOUT TECHNOKONTROL ANTI-EXPLOSION ALLOYS

ATEX/NFPA ANTI-EXPLOSION/SAFETY DISCHARGING-REFUELING VALVES FOR PETROL STATIONS, FUEL DEPOTS, REFINERIES, PETRO-CHEMICAL PLANTS

ATEX/NFPA ANTI EXPLOSION, ANTI-ELECTROSTATIC, ANTI-SLOSHING, ANTI-VAPOR SAFETY VALVES "CUSTOM MADE" FOR EACH CLIENT AND TECHNICAL-INSTALLATION REQUIREMENTS

ATEX-/NFPA PETROL STATIONS-MAN HOLES, STORAGE FACILITIES, REFUELING AREAS - ATEX-EU/NFPA EXPLOSIVE ATMOSPHERIC DIRECTIVE DANGER SECTIONS

ATEX-NFPA TECHNOKONTROL ANTI-EXPLOSION-SPECIALIST SAFETY TECHNOLOGIES

SPECIALIST UNIQUE PATENTED ALLOY FORMULATIONS & DESIGNS FOR ALL ENGINEERING-TECHNICAL REQUIREMENTS INCLUDING USAGE FROM PROTECTION-SAFETY TECHNOLOGIES TO PETROL-CHEMICAL-ENVIRONMENTAL INDUSTRIES

TECHNOKONTROL SPECIALIS ANTI-VAPORIZATION, ANTI-THERMAL & ANTI-ELECTROSTATIC CHARGES ALLOYS FORMULATIONS

ANTI-EMPS (ELECTROMAGNETIC PULSES/RADIATION), SPACE/SATELLITE/AVIATION EXTREME THERMAL HEAT ATMOSPHERIC RE-ENTRY ALLOYS, ETC.

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Petro-Chemical / Gas Tanks Protection

Petrol stations explosion videos

- Huge explosion in Seoul

- Petrol station explosion

- Fireball explosion

- Static electricity explosion

- Cell phone static electricity explosion

- Using cell phone while filling vehicle

- Petrol station fire

- Petrol station explosion

- Tanker explosion at petrol station

- Cigarette explosion

Security

- Institute of Petroleum - Guidelines for Soil, Groundwater and Surface Water Protection & Vapours Emissions

- Fire and Explosion in the Liquified Petroleum Gas Facility (ENG)

- Petrol Station Explosions Caused by Electrostatic Risks (SPA)

Los riesgos de ignición electrostática en las gasolineras-KPS (SPA) - Vaporización en gasolineras (SPA)

- Procedimientos de seguridad en terminales de hidrocarburos (SPA)

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects