TK-Bunding Safety Systems

Liquid Spill Safety Technologies

TK-BUNDING SAFETY SYSTEMS - BOILOVER-EXPLOSION AND LIQUID SPILL SAFETY TECHNOLOGIES

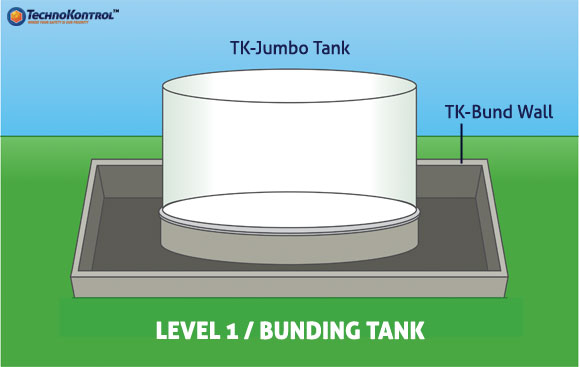

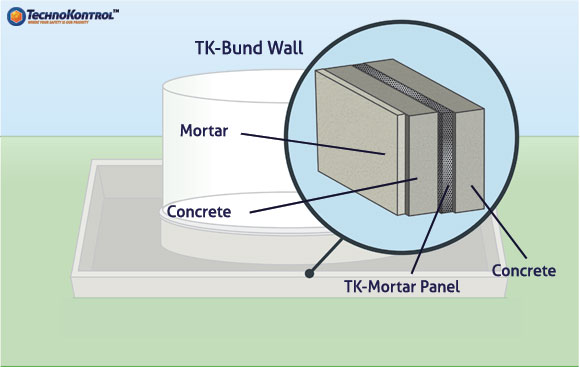

TK-BUNDING STRUCTURE DESIGN

TK-Bunding Safety Structures are constructed retaining walls designed to prevent inundations or breaches from a known source. They are secondary and third containment systems commonly used to protect environments from spills where fuels and chemicals are stored.

The TK-Bunding Structures have the great benefit of not only containing the stored liquids in case of an incident or emergency from the storage tank breakage, fire, explosion, boilover but also being designed and having incorporated inside the bund structure two thermal, fire and flame protection systems which in the event of an fire, explosion or even the disastrous boilover scenario the spilled fuels or chemicals which are extremely flammable and to which most possibly being ignited can´t weaken and/or melt the bund structure due to the massive, continuous thermal radiation reaching over the 900ºC in the event of a fuel fire from the storage tank.

Having these TK-Bunding Safety Systems incorporated in the bund structure allowing that even any continuous thermal flame, fire, heat exposure, radiation over many hours or even days being structurally prepared to support the bund structure integrity and even more importantly not allowing the liquids spilling over or penetrating into any other bunds, drainage, sewage systems thus not only reducing the risk of thermal flame or fire exposure from one site to another but also in protecting the environment and following any QSSHE corporate and/or government directives.

The TK-bunding must be large and strong enough to contain the contents of an entire tank, though regulations may require it to be up to a third larger. When multiple tanks share a bund, the capacity is based on the largest tank. One of the most common designs for large tanks is a concrete or masonry wall around the tank with a concrete floor. The outside of the wall may be reinforced with an earth

The TK-bund normally has a mobile, flexible cover or roof to prevent precipitation, climatic changes,dirt, debris from getting in, but procedures are taken to provide adequate ventilation when storing flammable liquids. Another design uses a channel that drains the liquid to a secondary containers.

TK-BUND FIRE, FUMES, IGNITION, VAPORIZATION SUPRESSION-DEACTIVATION-PROTECTION TECHNOLOGIES

The issue of having installed a specialist protection TK-Bund structure to withstand any amount of fuels, chemicals and/or liquids has been pointed out above but the most serious scenario being that the fuels once haven spilled into the bund structure being ignited and causing the storage, jumbo tank in being imbedded into a fuel fire pool/bund which again increasing the possibility of not only of the increasing of the fire but also creating a perfect environment for a BLEVE explosion.

Thus the TK-Bund design incorporates in the bund section a fully incorporated and installed alloy meshing which will not only stop the spilled fuel flames continuing to burn but also in a extreme case scenario in allowing the fire services to easily extinguish any flames by using TK-Anti Fire Textiles Blankets, foams or even water.

Once the spilled ignited fuels enter into the bund section, then the TK-alloys will not allow the fuel to continue its burning process. The bund will not lose its safety directive minimum volume capacity as having the TK-Alloys installed will only have a total liquid volume loss of 1%-2% depending on the final design.

TechnoKontrol Anti-Fire Alloy Mesh

Once the spilled fuels are safely located in the bund section these can be then drained into any emergency, environment protection drainage, pipeline, tank system or even being pumped back into any road tanker for fuel cleaning/filtering and being able to be re-used, if so desired, as the fuels chemical composition shouldn´t have changed and only being an issue the possible mixture with external debris thus recommending a full filtration and analysis before its re-use in its original form or in form of other products thus reducing product and financial loss.

The vaporization of any spilled fuel or chemicals being reduced are other benefits of the TK-Alloys and also protecting the whole structure against lightings, sparks, maintenance operation errors, etc.

The bund is also fully protected against oxidation, corrosion thus the external part of the fuel tanks which sit inside the TK-Bund section benefiting from the TK-Alloy its physical contact with the alloys/metal in reducing oxidation, electrostatic charges, electromagnetic waves, etc. The spilled fuels inside the bund will also have the benefit of not creating or developing algae thus located spilled fuels not emitting fuel decomposition odours.

TK-BUNDING QSSHE/QMSSHE PROTECTION LEVELS

LEVEL 1

PROTECTING THE TK-BUND STRUCTURE WITH THERMAL, FIRE, FLAME PROTECTION TK-ALLOYS/TK PANELS TO CONTAIN A FUEL FIRE OF A MINUMUM OF 6 HOURS AT 900º-1150ºC.(INTERNAL, INSIDE TO TANK, GROUND BUND WALL SECTIONS).

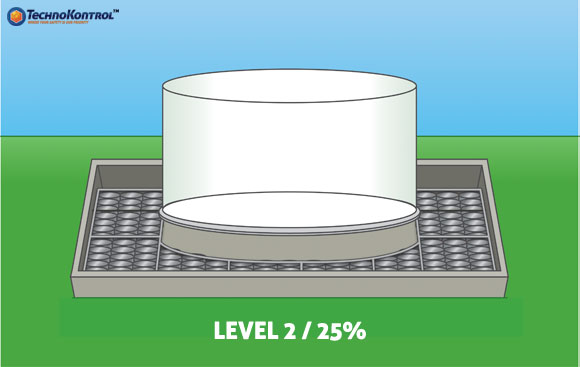

LEVEL 2

LEVEL 1 + LEVEL 2. THE BUND INTERNAL SECTION SURROUNDING THE STORAGE TANK AT 25% MINIMUM TOTAL FUEL STORAGE TANK VOLUME.

(Example: 1,000,000 litre fuel tank would requrie 250,000 litres of TK-Alloys).

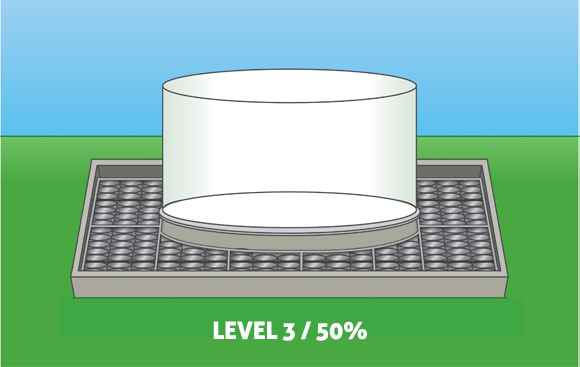

LEVEL 3

LEVEL 1 + LEVEL 3. THE BUND INTERNAL SECTION SURROUNDING THE STORAGE TANK AT 5O% TOTAL FUEL STORAGE TANK VOLUME.

(Example: 1,000,000 litre fuel tank would requrie 500,000 litres of TK-Alloys).

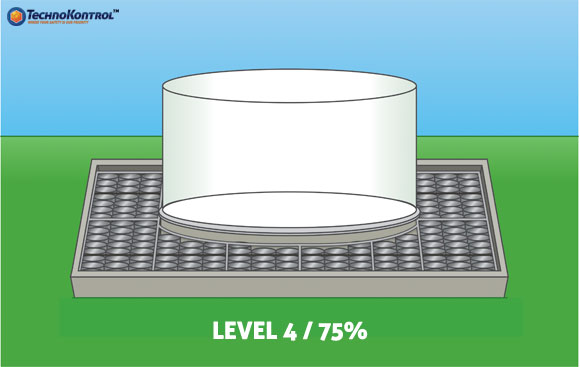

LEVEL 4

LEVEL 1 + LEVEL 4. THE BUND INTERNAL SECTION SURROUNDING THE STORAGE TANK AT 110% MAXIMUM TOTAL FUEL STORAGE TANK VOLUME.

(Example: 1,000,000 litre fuel tank would requrie 1,100,000 litres of TK-Alloys).

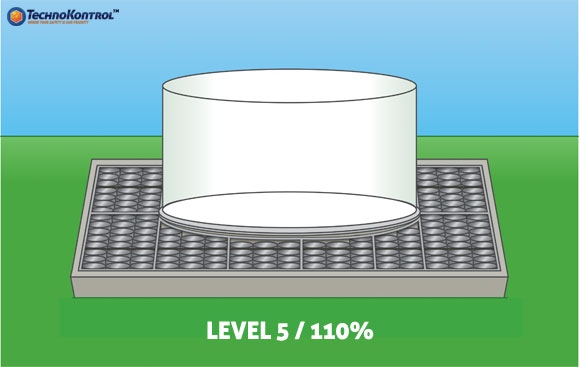

LEVEL 5

LEVEL 1 + LEVEL 4 + LEVEL 5. THE INSIDE OF THE STORAGE TANK FULLY PROTECTING WITH TK-ALLOYS WITH THE COMPLETE INTERNAL CAPACITY AND ALSO BEING FULLY PROTECTED THE TK-BUND AREA. THUS CREATING THE MAXIMUM LEVEL OF QSSHE PROTECTION POSSIBLE GLOBALLY.

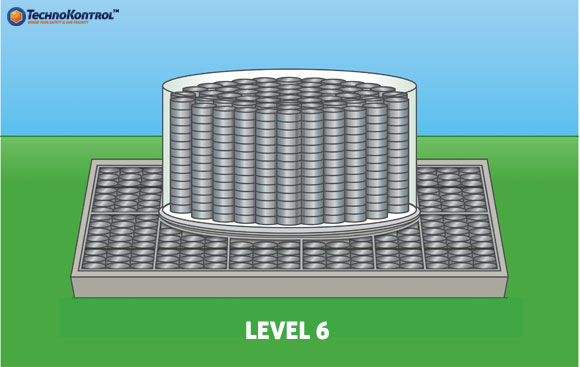

LEVEL 6

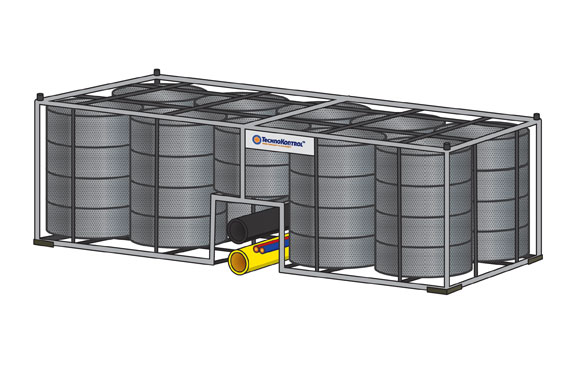

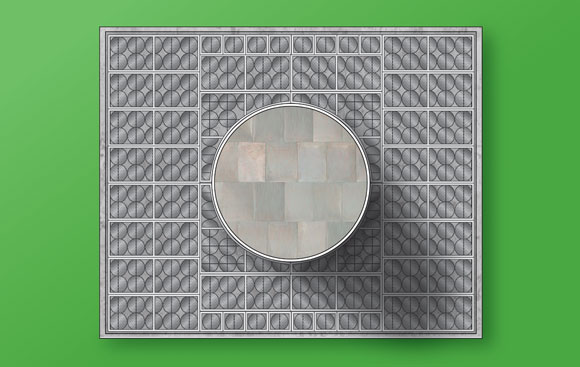

TK BUNDING CAGES

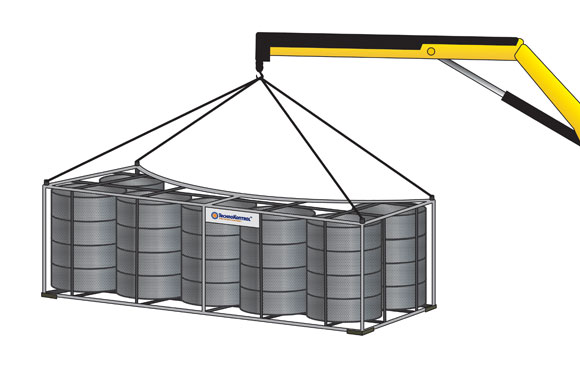

The TK Bund Area can be filled with different levels of TK Safety alloys which are transported, installed, stored in custom made -designed TK- Cages to withhold, secure, store the TK Safety Alloys during its operational life.

The TK Cages are made of stainless steel and inside their main frame tubular structures they are also filled with TK-Alloys to increase and able to withstand maximum thermal radiation, heat, flames and liquid movement in the event of the deposit, fuel tank suffering partial or complete structural failure a sin an explosion or boilover scenario.

The TK Cages are designed to fit perfectly into the TK Bund Area thus allowing the maximum protection due to its direct contact with the TK-Alloys but also allowing maximum contact, covering, protection with and around metal pipes, pipelines, cabling, metal structures as fuel tanks, store facilities, pumping stations.

The TK Bund Area is mapped out in 3D thus allowing a color, numeric and precise cage plan design allowing when needed to withdraw, relocate, transport, have access to all sectors inside the TK Bund Area and/or to do maintenance, cleaning, QSSHE operations at anytime as being easily transportable by means of light weight lifting machinery, cranes or even by several members of staff due to its extreme light weight properties.

QSSHE/QMSSHE Regulations

Bunding is a legal requirement in many countries particularly around tanks, storage vessels and other plant that contain liquids which may be dangerous or hazardous to the environment.

Particular examples which receive specific attention in the UK, the rest of Europe and the USA are oil and fuel storage tanks and transformers at electricity sub-stations which are filled with oil for cooling and insulation purposes.

It is reasonably easy to construct a "water-tight" bund around the base of a tank or vessel. A concrete base and a sealed wall of masonry, brickwork, concrete or even prefabricated steel provides the holding capacity.

Bunded oil tanks are generally a requirement from most insurance companies as opposed to single skinned oil storage tanks. Due to the safer oil storage solutions brought about by bunded oil storage tanks, some places in the UK can see the Environmental Agency require you to install bunded oil tanks.

Almost all regulations require a holding capacity of 110% of the largest tank within the bund or 25% of the total capacity of all the tanks within the bund whichever is the greatest. In addition further guidelines in some countries (e.g. the UK) recommend additional measures such as providing sufficient "freeboard" or height of wall above the maximum holding capacity to accommodate dynamic factors such as surge in situations of major tank failure or storm driven waves in larger bunds. As a rule (and unless specific local laws prevail) most operators work to the 110% capacity guide.

EXTRA BUND QSSHE REGULATIONS

Engineering against loss of secondary and tertiary containment

This section represents interim guidance, as PPSLG will undertake further work to develop more detailed guidance on secondary and tertiary containment.

While priority should be given to preventing a loss of primary containment, adequate secondary and tertiary containment remains necessary for environmental protection in the event of a loss of primary containment of hazardous substances.

The failure of secondary and tertiary containment at Buncefield contributed significantly to the failure to prevent a major accident to the environment (MATTE).

Minimum expected good practice

Bund integrity (leak-tightness)

Bund wall and floor construction and penetration joints should be leak-tight. Surfaces should be free from any cracks, discontinuities and joint failures that may allow relatively unhindered liquid trans-boundary migration. As a priority, existing bunds should be checked and any damage or disrepair, which may render the structure less than leak-tight, should be remedied.

Fire-resistant bund joints

Joints in concrete or masonry bund walls must be capable of resisting fire. Existing bunds should be modified to meet this requirement. In addition to repairing any defects in bund joints, steel plates should be fitted across the inner surface of bund joints, and/or fire-resistant sealants should be used to replace or augment non-fire-resistant materials.

Masonry (brickwork and block-work) bund walls

On older sites masonry bund walls are still in use. Vertical expansion and contraction joints and penetration joints rely on sealants to keep the bund watertight. These may require improvement to fire resistance. In addition, where significant cracks in masonry joints have been repaired with flexible sealant, these may also require improvement.

Bund capacity

he minimum capacity for bunds containing tanks in scope at existing installations is 110% of the largest tank.

Firewater management and control measures

Site-specific planning of firewater management and control measures should be undertaken with active participation of the local Fire and Rescue Service, and should include consideration of:

- Bund design factors, such as firewater removal pipework, aqueous layer controlled overflow to remote secondary or tertiary containment (for immiscible flammable hydrocarbons);

- Recommended firewater/foam additive application rates and firewater flows and volumes at worst-case credible scenarios;

- Controlled burn options appraisals Well-planned and organised emergency response measures are likely to significantly reduce the potential duration and extent of fire scenarios, and so reduce firewater volumes requiring containment and management. Site-specific planning of firewater management and control measures should be undertaken with active participation of the local Fire and Rescue Service, and should include consideration of:

- Controlled-burn options appraisal, and pre-planning/media implications.

EU-UK Environmental Oil Storage Regulations

The Oil Storage Regulations apply to all new installations in the UK- (both domestic and commercial). Oil is the commonest pollutant in the UK, accounting for one quarter of all incidents. These guidelines are intended to help reduce pollution caused by inadequate storage of oil in above ground oil storage tank installations.

Your environmental regulator can serve on you an 'anti pollution works notice' if your site gives rise to, or is at risk of giving rise to, pollution of surface waters or groundwater. This notice will require you to undertake remedial action.

Many drains lead directly to rivers, streams or lakes. If you allow oil to enter these drains, it has the same effect as pouring it directly into the watercourse.

Oil is poisonous to fish and other wildlife and it smothers plants. Just two liters of oil could seriously pollute the volume of fresh water needed to fill an Olympic-size swimming pool and make it undrinkable.

You may be prosecuted and fined if oil from your site enters the ground or watercourses. And you may have to pay substantial clean-up costs. The Oil Storage Regulations are designed to prevent oil spills.

Does your installation require bunding?

Is Secondary Containment of Oil a Legal Requirement?

Oil storage Regulations Definition: Secondary Containment, also often referred to as a bunded fuel storage tank, under the Oil Storage Regulations, an oil storage tank which qualifies should be contained within a secondary containment system totaling no less than 110% of the storage tanks full capacity, a bunded oil tank.

Other factors which require a Bunded Tank

Can you see the storage tank vent? If not you are required to bund the tank. An Overfill Prevention Valve will also need to be fitted in this instance.

You should also provide secondary containment (Bunded Tank) if the oil storage tank falls within a 10m of a water course (stream etc). Also use secondary containment if within 50m of a potable water supply or where spillages could run into drains or reach controlled waters.

Private Homes/Commercial Building Regs

A fire could be started by a fuel storage tank and its contents, However it does need to be protected from a fire that may originate nearby.

For example, tanks should be sited:

- On a solid base, level and at least 42mm thick, that extends a minimum of 300mm around the footprint of the tank

- 1800mm away from non-fire rated eves of a building

- 1800mm away from openings (such as doors or windows)

- 1800mm away from any appliance flue terminals

- 1800mm away from a non-fire rated building or structure (i.e.: garden shed)

- 760mm away from non fire rated boundaries (i.e. wooden fence)

If it is not possible to meet these requirements, a fire rated barrier with at least 30 minutes protection should be provided, extending 300mm higher and wider than each applicable face of the tank.

Download a copy of Section J of the building regulations.

OFTEC recommend that non domestic tanks equal to or below 3500L capacity should be located a minimum of 2m away from any buildings or boundaries. (6m for tanks above 3500L capacity).

If this is not possible, walls or barriers of at least 60 minutes resistance which extend 900mm beyond each applicable face of the tank should be used. (120 minutes rating for tanks above 3500L capacity).

Planning Permission

Domestic users will need to apply for planning permission to install a heating oil tank when:

- Greater than 3500L capacity

- Higher than 3m above ground level

- Nearer to the public highway than the closest applicable corner of the property*

Planning permission is also required for any domestic storage tank for fuels other than for oil fired heating applications (i.e.: LPG).

* does not apply if proposed site is greater than 20m from the nearest public highway

If you are installing an oil tank and/or connecting pipe work and you employ an installer registered with one of the related competent person schemes, you will not need to involve a Building Control Service

Commercial Applications

The Environment Agency are able to impose uncapped fines on anyone who causes any spill, it is not necessarily the responsibility of the site owner as it is the polluter who pays.

Other Requirements

It is important that the oil or fuel storage tank is inspected annually.

Section 5.1 (b) iii of the above regulations also states that all oil tanks should be labeled with information on how to respond to a leak.

Section 7 of the PPG26 pollution prevention guidelines states: “Spill kits containing materials such as oil or chemical absorbents and personal protective clothing should be on site”.

Remember

The Environment Agency is able to impose uncapped fines on anyone who causes any spill, it is not necessarily the responsibility of the site owner as it is the polluter who pays.

Video Presentations

- TechnoKontrol Safety Videos

- What is B.L.E.E.V.E.? Explanation

- Fuel explosion examples

- Fuel Barrel Flame Ignition & Welding Test - Prueba de Ignición y Soldadura en un Barril de Combustible

- Pipeline Explosion Test - Prueba Anti-Explosión en Ductos

- Security Test (SPA) - Prueba de Seguridad

- Heat Conductivity of TK Alloys - Conductividad térmica de malla TK

- Fuel Vaporization Test - Prueba de vaporización de combustible

- Types of TK Alloy Formats - Formatos de presentación de malla TK

- Alloy Vaporization Test

Documentation

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Bunding Safety Systems

Documentation

Seveso Inspections Series

The European Commission’s Joint Research Centre and the Belgian Federal Public Service of Employment, Labour and Social Dialogue, Chemical Risks Inspection Division

Environment Agency PPG’s

April 2012

Guidance on General Good Environmental Practice

General guide to the prevention of pollution, PPG 1, May 2001

A basic introduction to good environmental management that will help you avoid pollution incidents. This guidance refers to information in other PPGs and publications. This PPG is currently being reviewed and will be updated in 2012.

Works and maintenance in or near water: PPG 5, October 2007

If you are planning works near, in or over water, this guidance provides advice on how to make sure your work protects the environment and meets legal requirements, including waste management.

Dewatering underground ducts and chambers

PPG 20, March 2001 Provides information for the safe dewatering of underground ducts and inspection chambers. This guidance is due to be reviewed and updated in 2012.

Guidance for storing and handling materials and products

Above ground oil storage tanks: PPG 2, August 2011

Advice on how to store oil safely in above ground oil storage tanks and comply with the law (excludes oil refineries and distribution depots).

Get to know your oil tank, August 2011

A guide to looking after your above ground oil storage tank and avoiding pollution, written together with the Oil Firing Technical Association and the Federation of Petroleum Suppliers. We recommend you have a look if you’ve got a new tank at your home or business or if you’ve moved into premises with a tank.

Environment Agency/CIRIA Joint Guidelines: Masonry Bunds for Oil Storage Tanks

Guidance for the construction of simple, reinforced masonry bunds for oil storage tanks up to 3.5 metres wide and 1.2 metres high.

Refuelling facilities: PPG 7, July 2011

These guidelines describe good practice in fuel storage and management that can reduce the environmental risk of your site. These guidelines also refer to the storage and handling of other liquids commonly used in association with fuel storage and dispensing.

Defra Groundwater Protection Code: Petrol stations and other fuel dispensing facilities involving underground storage tanks.

Emission reduction solutions technical information (for example AdBlue), January 2011

Information to help you store and use emission reduction solutions (for example, AdBlue) safely, so they don't damage the environment.

Installation, decommissioning and removal of underground storage tanks: PPG 27, July 2007

This guidance note covers all underground storage tanks (USTs), including those containing petroleum, diesel, fuel oil, aviation fuel, waste oil, domestic heating oil and other potentially polluting materials such as organic solvents. This PPG is currently being reviewed for updating in 2012.

Drums and intermediate bulk containers: PPG 26, May 2011

These guidelines will help you if you are responsible for storing and handling drums and Intermediate Bulk Containers (IBCs). They are written for site operators of industrial and commercial premises.

Safe storage and disposal of used oils: PPG 8, February 2004

Advice on storing and disposing of used oils safely. This information applies to those carrying out a single engine oil change, to large industrial users. This PPG is currently being reviewed and is due to be updated in 2012.View / Download Guidance for site drainage, dealing with sewage and trade effluents

Use and design of oil separators in surface water drainage systems: PPG 3, April 2006

To help you decide if you need an oil separator at your site and, if so, what size and type of separator is appropriate. The separators listed in the document below have passed the performance type test in accordance with Clause 8.3.3 of the European Standard for Separator Systems, BS EN 858-1:2002:

Vehicle washing and cleaning: PPG 13, March 2007

Advice to help you protect the environment when you're washing vehicles using automatic wash systems, high pressure or steam cleaners and washing by hand.

Guidance to help you plan to deal with accidents and emergencies

Pollution incident response planning: PPG 21, March 2009

Good practice guidance to help you produce an incident response plan for your site to deal with accidents, spills and fires. Using this guidance will help to protect the environment.

Dealing with spills: PPG 22, April 2011

Good practice guidance to help you plan how you will respond to a spill on your site or if you are transporting materials. Includes information about the pollution control hierarchy and pollution control equipment options.

Environment Agency Technical Information Notes

Pollution prevention: Safe storage and use of de-icing products (issued December 2010)

Advice and guidance on the safe storage and use of de-icer products together with their potential environmental impacts.

Pollution prevention: Airfield management (updated April 2011)

Advice to protect the environment from common activities at private, commercial and military airfields.

Prevent pollution from drinking water treatment works and distribution networks

Advice to protect surface waters and groundwater from activities at water treatment works and distribution networks.

EU/UK SAFETY AND ENVIRONMENTAL DATA

Above ground oil storage tanks using bunds

Safety and environmental standards for fuel storage sites

Guidance on the Environment (Oil Storage) Regulations

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Security

- Fire and Explosion in the Liquified Petroleum Gas Facility (ENG)

- Petrol Station Explosions Caused by Electrostatic Risks (SPA)

Los riesgos de ignición electrostática en las gasolineras-KPS (SPA) - Vaporización en gasolineras (SPA)

- Procedimientos de seguridad en terminales de hidrocarburos (SPA)

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects