TK Fire Rated Doors

TECHNOKONTROL No 1 GLOBAL ANTI-FLAME/ANTI-HEAT RADIATION/ANTI THERMAL EXPOSURE DOORS

Fire rated doors and frames play a vital role in keeping people safe and minimizing property damage during a fire. Hollow metal doors are excellent at limiting the danger and damage of fires. The normal, hollow metal is the only material widely available with a 3-hour rating, however each country has different heat/flame tests and the norm range from 175ºC/343ºC to 540ºC/650ºC at testing in USA and in Europe.

The testing standards in some countries may reach the 1093ºC for furnaces type testing up to 4 hours but again the thickness and weight reduction of the TK-Doors being unique with the advantage that the TK Door interior of the door requires less then 18mm(1,8cm) thickness and doubles the present test level of 240 max testing standards against the TK-Door 480 minutes protection and even higher.

TK DOOR/PANEL Construction Division designs, manufacturs and installs our unique patented doors, underground mine gates,underground tunnels, mine shafts entrances/exits with the highest fire, heat, thermal radiation protective technologies which can commonly be installed in stairwells, offices, hotels, hospitals of any trp of building and of course also of many high-rise buildings, tower blocks, shopping centres because they allow people to safely transit to/from any of the building floors with fire, massive heat exposure, thermal radiation, protecting all person aand recuing the fire expansion.

NFPA TESTING AND REGULATION STANDARDS WHICH TK-DOORS SURPASS BY OVER 100% IN MANY TESTS

The NFPA requires annual inspections of fire-resistance rated door and frame assemblies. Local Authorities having Jurisdiction must adopt the new edition for this requirement to take effect. Most jurisdictions in the US will be adopting the IBC (International Building Code) model code, which references the NFPA 80 2007 edition requirement, as their local codes.

Most fire doors are designed to be kept closed at all times. Some doors are designed to stay open under normal circumstances, and close automatically in the event of a fire. Whichever method is used, the door's movement should never be impaired by a doorstop or other obstacle. The intumescent and smoke-seal bounding of fire doors should be routinely checked, as should the action of the door closer and latch.

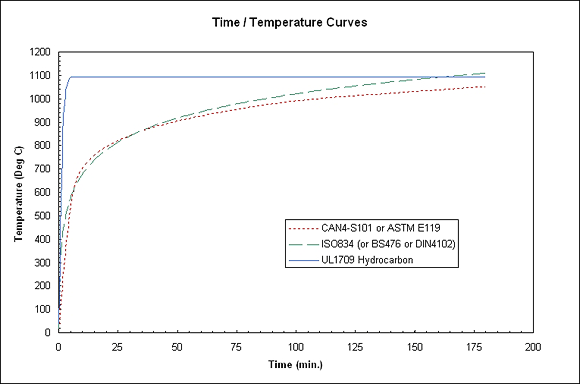

Normal rated fire doors are tested to withstand an ASTM E119 standard time-temperature curve for a specified period.There are 20, 30, 45, 60 and 90-minute-rated fire doors that are certified by an approved laboratory designated as a Nationally Recognized Testing Laboratory.

TK Doors have the unique advantage of not only in reaching and surpassing all the top testing levels of the best present manufactures and testing laboratories but also increasing all global testing standards beyond any other manufacturer, authourity by at least 100%.

TK Doors have the great advantage of easily reaching the 480 minute range and even further with acontinuios heat/thermal/flame contact in the range of 900ºC to 1200ºC.

TK Doors fully meets all of the NFPA 80- 2007 edition testing requirements.

DIN ISO ASTM UL Curves

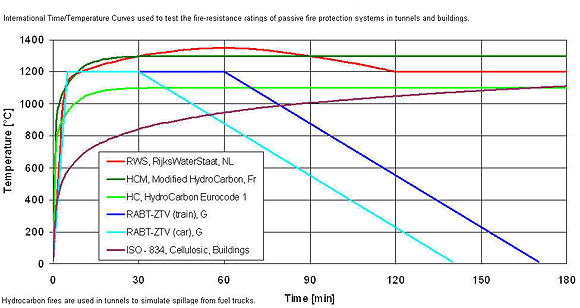

Tunnel HC ISO Curves

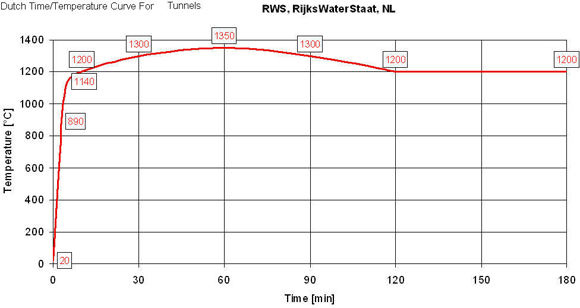

RWS Tunnel Curve

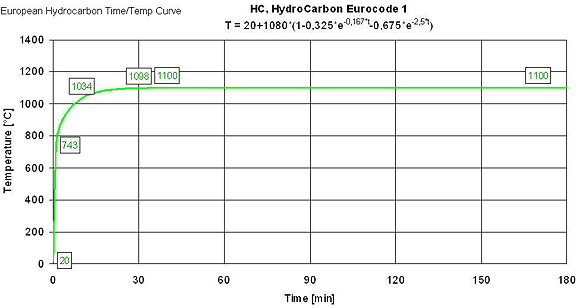

Eurocode 1 Curve

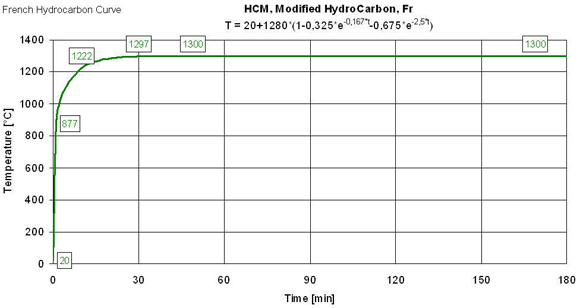

French HC Curve

TK-Vault-Safe Tests for fire resistance of record protection equipment

Class 100

This rating is the requirement in data safes and vault structures for protecting digital information on magnetic media or hard drives. Temperatures inside the protected chamber must be held below 125 °F (52 °C) for the time period specified, such as Class 125-2 Hour, with temperatures up to 2,000 °F (1,090 °C) outside the vault. The temperature reading is taken on the inside surfaces of the protective structure. Maintaining the temperature below 125°F. is critical because data is lost above that temperature threshold, even if the media or hard drives appear to be intact.

Class 150 Rating

This is the rating required to protect microfilm, microfiche, and other film-based information storage media. Above 150°F (65.5°C) film is distorted by the heat and information is lost. A Class 150-2 Hour vault must keep the temperature below 150°F. for at least two hours, with temperatures up to 2,000°F. (1,093.3°C) outside the vault.

Class 350 Rating

This rating is the requirement for protecting paper documents. Above 350°F (176.7°C) paper is distorted by the heat and information is lost. A Class 350-4 Hour vault must keep the temperature below 350°F. for at least four hours, with temperatures up to 2,800°F.(1,093.3°C) outside the vault.

- ASTM E119 Fire Testing on Bulding Construction and Materials

- ASTM E119.09a Fire Testing on Buildings Construction and Materials

TK Doors fully meet all of the NFPA 80- 2007 edition testing requirements

- Fire Code Institute

- The Flammable and Combustible Liquids Code, NFPA 30

- The Automotive and Marine Service Station Code, NFPA 30A

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Videos

- TechnoKontrol TechnoPanel

- Watch video of stable wall at 1600°C

- NFPA 286 Regulations wich TK surpass by over 100%

Civilian, Commercial, Industrial, Bunkers, Panic Room Protection

Military, Law Enforcement, Civil Construction Protection

Documentation

- FEMA WTC 1 and WTC 2 (PDF)

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects