TK-Fire/Thermal/Bullet Proof Panel

TECHNOKONTROL BULLET PROOF & THERMAL / FIRE SAFETY TECHNOLOGIES.

Introduction to Bullet-Resistant & Thermal/Fire Protective Materials

Purpose:

Bullet-resistant materials are commonly used where the threat of attack by an armed criminal is likely. While the level of security risk at most facilities doesn't warrant the use of such materials, some facilities, due to the nature of their operation or their location, do find the use of bullet-resistant materials to be a necessary security precaution.

Bullet-resistant materials can both protect employees as well as discourage robbery attempts and other types of crimes involving the use of a firearm. Bullet-resistant materials are commonly used at banks, pharmacies, check cashing centers, and other businesses that handle cash or narcotics in high-risk neighborhoods. Bullet-resistant materials are also used at public facilities such as police stations, jails and courthouses.

In recent years, certain types of facilities that didn't previously use bullet-resistant materials are now using them. For example, hospitals in high-crime areas now use bullet-resistant materials on the exterior of their Emergency Departments to protect against gang-related drive-by shootings. Also, some data centers now install bullet-resistant materials in their lobbies to prevent forced takeover of the facility by armed attackers.

Type of Bullet-Resistant Materials:

There are four main categories of bullet-resistant materials: bullet-resistant glazing, bullet-resistant panels, bullet-resistant doors, and bullet-resistant accessories.

Bullet-Resistant Glazing:

Bullet-resistant glazing is probably the best known type of bullet-resistant material. Bullet-resistant glazing is used when ballistic protection is needed, but direct visual contact is also required between the protected area and the non-protected area. Bullet-resistant glazing is commonly used at bank teller cages and other types of service counters, providing protection between the public area and the area that contains the cash or other valuables. Bullet-resistant glazing is also used on the interior of lobbies, providing separation between the public and non-public side of the lobby. In addition, bullet-resistant glazing is sometimes used on the exterior of the building to protect against stray gunfire or attacks from a sniper.

There are four commonly used types of bullet-resistant glazing, each with their own advantages and disadvantages. The following is an overview of each type of material:

Laminated Glass:

Consists of multiple layers of glass laminated with protective interlayer, usually polyvinyl butyral (PVB).

- Least expensive type of bullet-resistant glazing.

- Suitable for both indoor and outdoor use.

- Scratch-resistant.

- Because it is glass, it can be broken, and does not provide protection against a sustained physical attack.

- Heaviest type of bullet-resistant glazing; weight may require special structural considerations.

Acrylic:

- Suitable only for indoor use.

- One-half the weight of glass.

- Scratches relatively easily unless provided with special coating.

- Available only in lower ballistic ratings.

- Offers some degree of protection against physical attack.

Polycarbonate:

- Suitable only for indoor use.

- Weighs less than glass.

- Best ability to fully capture incoming bullet, prevents ricochets and spalling.

- Offers protection against physical attack.

- Has slight grayish tint; not as clear as glass or acrylic.

- Scratches relatively easily.

- Costs more than laminated glass.

Glass-Clad Polycarbonate:

- Consists of polycarbonate with a layer of glass added to it.

- Suitable for indoor and outdoor use.

- Glass side resists scratching and provides weather-resistance.

- Weighs less than glass.

- Offers protection against physical attack.

- Has slight grayish tint; not as clear as glass or acrylic.

- Costs more than laminated glass.

Technokontrol Bullet-Resistant Panels:

Bullet-resistant panels are most commonly used to protect the walls surrounding the openings where bullet-resistant glazing is used. For example, if bullet-resistant glazing was used at a customer service window in a pharmacy, bullet-resistant panels would be used in the wall on both sides of the window as well as below and above the window itself.

The use of bullet-resistant panels allows walls to be constructed using standard stud-wall construction techniques rather than requiring that a concrete or masonry wall be provided. Bullet-resistant panels are typically fastened to the studs and then covered with regular drywall. When painted, the bullet-resistant wall looks like any other.

There are two popular types of bullet-resistant wall panels: steel, and fiberglass composite. Steel wall panels are the least expensive but weigh more. Steel wall panels are difficult to work with on the job site and usually must be ordered from the factory in the desired size.

Fiberglass composite wall panels cost more than steel wall panels but weigh about half as much. Fiberglass composite panels are much easier to work with and can be cut and drilled on the job site.

Bullet-Resistant Doors:

Bullet-resistant doors are used when a door is required in a wall that forms part of a bullet-resistant barrier. Bullet-resistant doors are specifically designed to provide ballistic protection and usually come as a complete unit consisting of both door and door frame. Bullet-resistant doors come in both wood and metal versions and are available with or without windows.

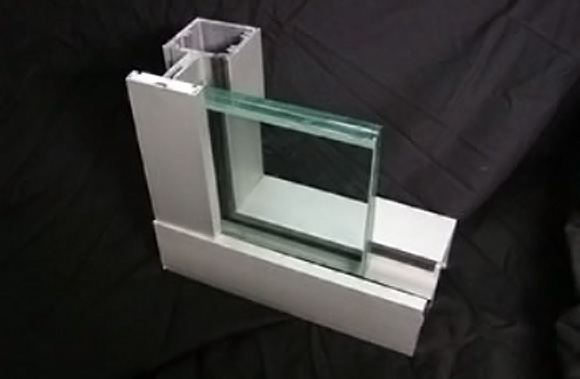

Image: Bullet & Thermal Protection Security Entrance.

Bullet-Resistant Accessories:

Bullet-resistant accessories are used when it is necessary to pass objects through a bullet-resistant barrier. Bullet-resistant accessories are also used to allow direct audio communications between both sides of the barrier. Bullet-resistant accessories include speak-through devices, money trays, gun ports, and package receivers that allow packages of various sizes to be passed through the barrier.

Image: Bank Teller Bullet Proof Glass

Image: Administration Office Bullet proof window.

Bullet Resistant- Physical Attacks, Fire Testing Images:

Image: Bullet Proof, Thermal, Fire Proof, Security Office/Control Centre.

Image: Physical, Bullet, Ramming Testing.

Image: Bullet Proof Doors and Window.

Image: Bullet Proof Testing.

Image: Thermal/Fire & Bullet Proof Testing

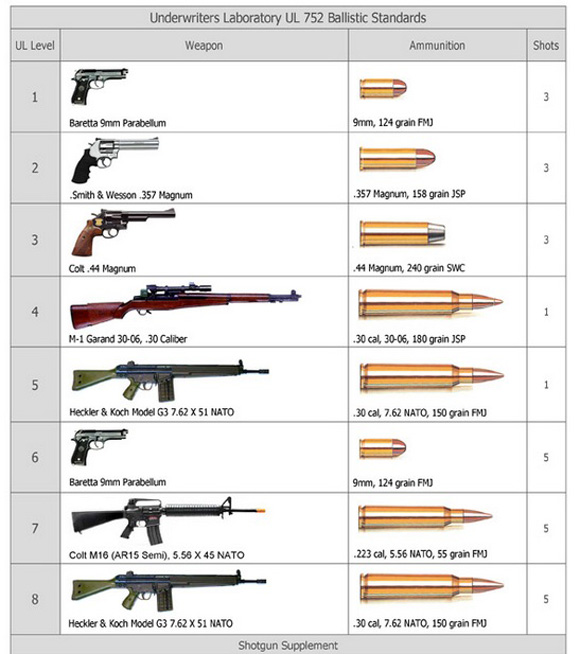

International Ballistic Ratings:

Bullet-resistant materials are sometimes incorrectly called "bullet-proof" materials. Most of these materials are in fact not bullet-proof, but only provide protection against a certain range of types of firearms for a certain period of time.

Firearms are available in a wide variety of calibers, each which have a different ability to penetrate a bullet-resistant material. Even within cartridges of the same caliber, there are different bullet weights and types and different powder loadings. Rifle cartridges generally have much more power than handgun cartridges, and shotguns may pose a different type of threat than either handguns or rifles. Repeated gunfire against the same surface also has a different effect than a single bullet does.

To help sort through all of these variables, Underwriters Laboratories (UL) has developed a written standard, UL 752, that establishes ratings for bullet-resistant materials. UL 752 specifies eight levels of bullet-resistant ability, ranging from Level 1 to Level 8. The most common ratings used by commercial businesses are:

- Level 1 - Provides protection against 9mm and less powerful handgun cartridges.

- Level 2 - Provides protection against .357 magnum and less powerful handgun cartridges.

- Level 3 - Provide protection against .44 magnum and less powerful handgun cartridges.

Level 4, 5, 7, and 8 are generally needed to provide protection against common rifle cartridge calibers. UL 752 also has supplementary ratings for threats from a shotgun.

In general, the higher the rating level, the better the protection, but the greater the cost. Higher rated materials are also generally thicker and weigh more, and there may be a limited availability of materials and accessories at the higher rating levels.

Suggestions for Using Bullet-Resistant Materials:

1.)-The decision to use or not use bullet-resistant materials should only be made after a comprehensive security assessment has been conducted. The security assessment should provide guidance as to where bullet-resistant materials should be used, and establish the minimum UL rating level required based upon the level of risk at the specific facility.

2.)-A systems approach must be taken when designing a bullet-resistant barrier; the wall, glazing, and any accessories must all be rated to provide the minimum desired UL rating level. It doesn't make sense to provide a Level 3 rated window when the wall surrounding the window is unprotected. Also consider the possibility of ricochet and the potential for a bullet to penetrate the adjacent walls, ceilings, and floors.

3.)-Always use materials that are UL listed and labeled. Some manufacturers can be deceptive and use terms such as "tested to UL standards", "meets requirements of UL Level 3", etc. even though their products haven't actually been tested by UL.

4.)-The thickness and weight of bullet-resistant materials can have an impact on building construction and may affect everything from the size of the structural beams to the type of window coverings used. Be sure to involve your architect or other design professional in the planning of your bullet-resistant system.

5).-Employee security awareness training must be provided in conjunction with the installation of a bullet-resistant barrier. Employees need to know how to react when a weapon is presented, even if they are behind a protective barrier. Employees may also be at increased risk when entering or leaving the protected area, and need to be given guidelines on how this can be accomplished safely.

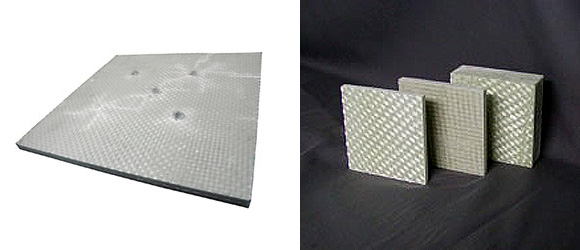

Technokontrol Bullet-Proof & Heat/Fire Resistant Wall Panels

Due to many of Technokontrol clients being governments, large international corporations and private individuals based in countries where the risk of terrorism or sabotage is greater due to geo-political or religious/social/military/crime issues we have the possibility to combine our heat/fire resistant 13mm thick wall panel which protects up to 1600º direct heat/fire blast for over three hours with a Level III bullet Proof protection panel.

Due to both panels not extending in joint/combined dimensions 26-30mm this is a great product to stop fire/heat exposure due to accidental fire, terrorism or fire bombs attacks and at the same time direct arms attacks up to Level III-VIII+. In the event of the client wishing to increase either or both levels or protection this can be easily done by joining more panels to increase its protection levels.

Panel protection: up to 1600º direct heat/fire blast for over three hours with a Level III-VIII+ bullet-proof security panels attached, annexed, etc.

The use of the Technokontrol Fire / heat panel is also extremely interesting especially in high level buildings as skyscrapers or tower blocks where fire is the real danger to these buildings as time becomes a " life or death" situation as in many cases seen recently in the media around the world where even the fire services couldn´t reach the higher parts of the tower blocks and the internal fire emergency systems have failed causing many injured and human deaths.

The use of our Technokontrol heat/fire panels offers our client more than three hours of protection of fire / heat exposure containing the fire in all or selected protected areas and to increase the chances of evacuation and allowing more time for the local fire or internal emergency services to arrive and to assist.

As crime is becoming a daily and more of a common issue around the world and at any time a criminal group may decide to attack / rob a clients home or business using our joint panels Fire/heat-Bullet Proof reassures our client that his building has enough protection to withstand a direct fire arm attack during some time until the police or security services arrive and assist the clients. In the event of using our panels another great benefit is the little use of installation overall space required of 26-30mm which allows any client or building firm not to lose great amounts of valuable space lost in the internal or external walls of the building and also reducing overall weight of the building / structure but maximizing the building security and overall its protection to the highest levels possible.

The Technokontrol panels can be attached on to already present walls or can be used as internal new panels hence the client than can install the panels in new buildings and for already built buildings as the client may wish to only use them in certain areas or exposed areas of their homes or businesses allowing the client to decide where he may require these protection panels. Depending on the design of the building we can arrange that the bullet proof panels to made of flexible bullet proof/Fire/Heat proof textile materials or hard wall panels allowing again for the client to decide of any type of design or unusual forms or shapes of their buildings, homes, offices or even security "anti-panic" rooms or private bunkers.

Technokontrol in the Secuirty, Safety,Construction, Law Enforcement & Miliatry Industries.

In an industry where there are more and more accidents occurring every year both on a residential and industrial basis, we at TechnoKontrol believe that it is vital that we keep working so as to improve the quality of the products used within the Construction Industry.

Therefore we promise to work alongside all governmental agencies and architects so as to work towards changing legislation in order to ensure that the construction industry becomes both safer and more cost effective in the areas of anti-explosion, non flammable and heat resistant products.

Although we are constantly working so as to bring new products to the market place, at present we can provide our customers with the following products.

Anti Explosions; non flammable; heat resistant Wall/Ceiling and Duct Systems along with Board Panels/Collar Systems which are usable both in the Industrial and Residential industries alike.

We believe that our products are more durable than that of our competitors as our products can withstand 1600°C for up to and past 3 hours, whilst current industry standards shows us that our competitors products can only withstand 650°C for up to 1 hour. Our products are also thinner than that of our competitors as our products only measure 13mm in width and finally we believe that our products are more cost effective (customized quote provided on application) than what is presently recognized as the current industry standard.

TechnoKontrol is currently working with many of the world's largest insurance companies so as to reduce insurance premiums by between 15%-30% on any item that carry's our specially designed product.

Technokontrol Wall-Ceiling System

At TechnoKontrol we are proud to announce that we have developed the thinnest, safest and most financially viable “fire proof wall system” currently available in the market place today.

Our Wall System is built around a plaster composite panel with a non-combustible mineral alloy fibre made with our exclusive VI-VII-VIII alloy core. This is ideally suited for the construction of non-load bearing walls and offers an "any climate" dry installation.

Of its many features the one which is most popular with our current clientele is that of our Wall Systems ability to be dismounted and reused in any new location, as this is something that no other fire rated wall assembly can offer in today´s market.

Our TechnoKontrol Wall system is available as standard in an aesthetic smooth white finish however, alternative colours and finishes are available on request.

|

Available standard size |

Protection |

|

13mm (1.3cm) thickness |

+3 hour fire rated wall @+1600°C |

If a customer wants a panel thicker or more resistant to fire can do, with a price increase by using more sophisticated alloy or as something much more but that is a matter of special customers.

Benefits of our Technokontrol wall systems are:

- Reduces installation and scheduling time.

- Predictable - simple and easy to install allowing for more accurate project completion dates.

- Large manufactured components deliver consistent high standards of quality and performance.

- Cost competitive in many applications, both for new and retrofit projects.

- As TechnoKontrol works in conjunction with all major insurance companies we are confident that we are going to be able to reduce your insurance premium by at least 15%-30%. For further information contact one of our financial experts today.

Board Panels

TechnoKontrol Fire Resistant Boards

We are proud to announce that we are able to provide one of the thinnest, safest and one of the most cost effective fire resistant boards currently available in today´s market. At present we are able to provide a board as thin as 13mm (1.3cm) that is able to withstand 1600Cº for over 3 hours. At present our R&D team is working hard so as to improve both the thickness level (i.e. make an even thinner board) and to make it more durable (i.e. withstand even higher temperatures for a longer period of time).

As with all of our TechnoKontrol products, our Fire Resistant Boards are manufactured and can be tested by independent and nationally approved laboratories.

The TechnoKontrol Fire Resistant Boards are designed and built to suit any fire protection application. Its box cladding solutions allows for maximum utilization of the material and there is a limited to no clean up, waste or disposal of the product after use.

These plaster and exclusive VI generation alloy based boards are non-combustible, and can be cut/installed with standard wood-working tools. We can also customize our product so as to produce panels made of plaster or even wood via introducing our patented fire resistant product into the respective material.

Hence ensuring that our TechnoKontrol Boards can be used for various different types of jobs such as providing fire protection to

- Partitions & masonry walls

- Steel beams & columns

- Electrical & mechanical services enclosures

- Ductwork as well as ceilings.

Therefore we have produced the TechnoKontrol Boards so as you (our customer) will be able to meet all of your passive fire protection needs which may include one of the following:

- Protection for structural steelwork

- Pipes, cable and other service enclosures

- Ventilation fire rated duct

- Floors and ceilings

- Internal walls and partitions

- External walls

- Doors

- Enclosures

- Concrete structure protection

- Cavity barriers

As with all our TechnoKontrol products, the TechnoKontrol Boarding systems are easily installed and offer many additional features, some of which include:

- It can be installed at any temperature or in any weather condition

- It offers a superior performance with a drywall type finish

- It has been proven to offer an extremely high level of fire protection

- It is moisture resistant

- It offers a Zero clearance & has been proven to be impact resistant.

- It is built so as to provide the thinnest board possible within current regulations which in turn allows our TechnoKontrol Boarding system to offer a fire protection within the tightest of space requirements

TechnoKontrol Fire-Rated Floor and Ceiling Systems Provide Safety, Security and Strength.

National statistics show that a fire breaks out in a structure every 60 seconds and that the subsequent damages amount to more than 12 billion Euros a year.

Passive fire prevention products have been proven to stop the spread of fire and reduce the damage. Current construction codes within new buildings require that specific floors and ceilings must include what is known as fire separations. These are aimed to compartmentalize buildings thus, protecting them from the spread of fires and smoke.

Older buildings however were not necessarily built to the same code requirements of today hence; many managers are retrofitting their facilities in order to reduce the risk of the loss of life and property damage whilst in turn also benefiting from lower insurance premiums.

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Civilian, Commercial, Industrial, Bunkers, Panic Room Protection

Military, Law Enforcement, Civil Construction Protection

Video

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Documentation

- E.U. Strategic Fuel Reserves Directives 2012

- E.U. Strategic Fuel Reserves Directives 2006

- Protección de Infraestructuras Estratégicas y Críticas en la U.E. (SPA)

- Institute of Petroleum - Guidelines for Soil, Groundwater and Surface Water Protection & Vapours Emissions

- Ley de Hidrocarburos y de Seguridad Nacional de Abastecimiento (SPA)

- Protección de Refinerías (SPA)

- Almacenamiento Inflamables Combustibes (SPA)

- Almacenamiento Productos Químicos (SPA)

- Directiva del Parlamento Europeo y del Consejo 94/9/CE, relativo a los aparatos y sistemas de protección para uso en atmósferas potencialmente explosivas (SPA)

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects