TK-AXPLSS Anti-Explosion Pipeline Safety System

Techno-Kontrol Pipelines

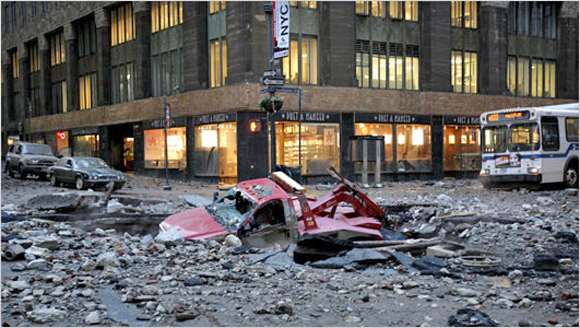

It is common knowledge that all types of pipelines carry a high risk of igniting the transported gas media and as this gas media (once ignited) transports the flames via a domino effect, more times than not a large explosion is almost certain to take place (i.e. as occurred within the Gulf of Mexico throughout 2010).

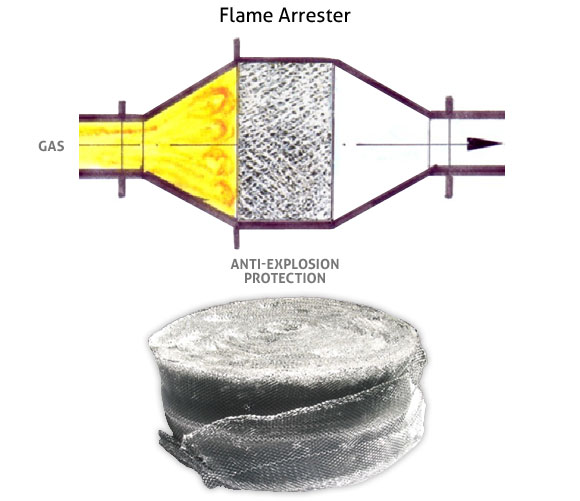

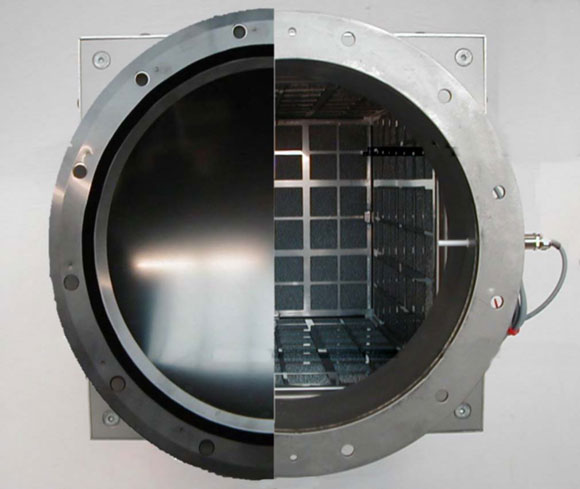

These types of accidents are more likely to occur when repair works are taking place within the pipeline due to the gas vapours hitting O2. However if Techno Kontrols “Flame Arrester” is installed within the pipeline (as seen below) these flames will be extinguished and any type of explosion will be not take place.

Security decking for Petrochemical Installations on offshore Drilling Platforms

Techno Kontrol is seeing a steady increase of demand for its product in all production units where inflammable products such as oil and chemicals can be spilled on the gangways and/or decks especially in hot climates where spilled materials can take place and the gas is then located in the under channels of the decking thus if a fire or spark was to occur an explosion would always take place. With the use of our product we would prevent these large explosions from taking place.

Our security decking’s are placed on the existing floors or gangways of the production unit and they help to gather the spilled inflammable materials so as to transport them through the under channel and collect the materials into gathering pipelines. The gangway can be filled with either Techno Kontrol balls or mesh and can be installed by hand.

Corporate vision for Pipeline Installations

Technokontrol has an exclusive department for Pipelines installations and safety products unique to the industry and is a highly professional organization providing the finest solutions for Central Liquefied Petroleum Gas systems, crude, chemicals and fuels to all established Industries, Buildings, Hospital, etc. We are a full service company committed to lasting business relationships believing in integrity, quality, and excellence in client service and support.

Mission and Development for Pipeline Projects

To grow our business and extend our market share to earn our customer’s loyalty and awareness of our capabilities by delivering on time quality projects and gaining customer satisfaction utilizing world class services & resource. Currently, we work with private, government, Industrial and commercial levels, our knowledge service oriented people work closely with customers to provide consultancy, safety and comfort that exceeds their expectations.

Technokontrol is providing customers with excellent services and products are the result of constant improvement and innovation at the highest quality level. Outstanding competence, extraordinary team spirit, visionary management is the key factors for being number one in terms of customers’ satisfaction and safety for the client, environment and employees.

Technokontrol Pipeline "Full Package" Services

Technokontrol is capable to provide “key in hand "delivery with full optional packages to increase safety and efficiency:

- Preliminary Project Study

- Design & Re- Design

- Installation including the networking as well as the storage facilities.

- Commissioning

- Supply

- Customer focused annual Maintenance agreement for existing systems

- Performance Measurement

- Customer Training

Planning Methodology

A properly managed Technokontrol site only requires minimum monitoring.

A properly Technokontrol monitored site reaches excellent productivity and enhanced output.

1. The total information system is centred on micro level estimation of cost at the element level, translating the contract amount to minute elemental level cost for costing and budgeting, which would be later used as the control measure.

2. To facilitate such detailed costing, necessary data has to be built up over the years on various types of job, various locations, various environments etc.

3. The control mechanism is built on a 2-tier system for the site viz., Work Breakdown Structures (WBS), which are controlled by Operation Manager and Work Packages (WP), which form part and parcel of WBS. In a site, different systems, which could separately traced and distinctly identified, would be called as different system, which could be separately traced and distinctly identified, would be called as different WBS. For each WBS there would be one man in charge (Operation Manager) and he would be held responsible for the costs pertaining to the WBS. The system would throw up feedback information regarding a particular type of work incidentally.

4. When it comes to Work packages, a group of packages would form a WBS. Work Package would comprise of work relating to a homogeneous group of activities of a WBS and hence would also help in the process of proper estimation for future job.

Estimation

The estimation is done for the following categories of cost, which would be called as subheads of expenditure.

a) Direct Labour

b) Support Staff/ Supervisory manpower (called as “Contractor Staff”)

c) Construction Equipment/Aids

d) Temporary materials

e) Erection Tools

f) Consumables

g) Mobilization and demobilization (travel & transport of men and machinery)

h) Insurance

i) Ancillary

j) Material handling

k) Commissioning assistance

l) Any other supply items

Technokontrol Budget

After completing Estimation in great details, as listed in previous paragraphs, the Senior Manager person does the budgeting. Budget is broken into three levels viz. Estimator’s Budget, Manager’s Budget and Corporate level budget. The corporate budget is the stripped down version of the overall estimation. The manager’s budget is a contingency. The estimator’s budget forms part of the manager’s budget but is devoid of any provisions of contingency. After the budgeting process costing is done. While the estimation and the budgets are according to the heads of expenditures as given in the paragraph on Estimation, the costing is based on WBS, WP and heads of expenditure. This means that for each WBS, cost with respect to every head of expenditure is reached at. Such an exercise is done for every single WBS. The total cost of all WBS would be equivalent to the total budgeted amount. The total budgeted amount could also be broken into different heads of expenditure by adding the values of different WBS. Thus, there would be a total picture of cost looking at it from either the WBS angle from the head of expenditure angle. Work packages are very smaller and are nothing but miniature of WBS in concept.

Manpower Scheduling & Labour/Man Power

The various activities in the project are fitted into the overall time schedule in terms of different months. The requirement of manpower for each of the categories is estimated on the basis of assumptions made at the estimation stage in terms of manpower and the time frame as decided. The manpower schedule is drawn in terms of each category of manpower on the frame. The charging of manpower is done to the respective WBS. The starting point is the overall schedule, which is given by client, and this is split up into weekly, fortnightly and monthly schedules.

Manpower Monitoring

The direct labour, which generally has more percentage contribution, requires close monitoring. This shall be monitored for each WBS and WP. Also the information forms basis to compute:

- Efficiency of manpower

- Composition of trades

- Costing for future projects

Progress Measurement

One method of Progress Measurement is based on billing value. Billing is done based on agreed milestones. The primary input for billing is only the total man-hours deployed. Projects are divided into two categories – labour oriented and equipment oriented. For the purpose of such a categorization, the total cost as estimated and budgeted for labour and rest of the components is compared and if labour outweighs the other components, it is termed as labour oriented and vice – versa. The ratio of this comparison is used as a weighing factor for estimating the progress. There can be other methods of progress measurement also defending upon client’s agreement.

Inventory Control

Inventory control is exercised at the level of WBS, based on monthly reports. Based on value and life, an item is categorized either asset or inventory. Control is exercised on inventory items and charged 100% to the projects. As regards assets, 100 % value is charged to the project but the salvage value is also taken into account at the end of the project defending on whether it is sent to another project or disposed of etc. Control on certain categories of consumables like the electrode requires systematic analysis of theoretical requirements and comparison with actual requirement.

Engineer OFB Contract and Claims

Knowledge of contract is essential for everyone. However, there should be a designated Engineer of contract who is authorized to study and point out deviations on jobs in site.

Equipment utilization

All construction aids/equipment are analysed with respect to their utilization and this utilization and this utilization factor is recorded as measurement of the extent to which the equipment is utilized in comparison to the total hours for which it has been made available at site. Also the fuel is recorded for proper monitoring which forms as basis for future project estimation.

Materials handling

The permanent materials should be segregated based on WBS and WP and also should be stored in yard accordingly. This will eliminate double handling of materials thus saving manpower and machine hours.

Drawing control

The drawing used should be approved for construction drawing. This defends on the method of drawing issue by client. Segregation of drawing based on WBS, WP and also relevant materials in advance based on Master drawing list has to be done.

Weather

Day-to-day recording of weather is also carried out and reported on monthly basis. This information is used primarily to analyse shortfalls in productivity and progress. Also it is used for time extension against liquidated damage.

Inspection and Testing

Technokontrol maintains a quality inspection and testing procedure in all stages from raw material selection to final installation for its consistency of the system.

Receiving Inspection & Testing

The incoming product routine check carried out against the test approval of central all national petrol-chemical regulations.

Calibration of measuring equipment’s

The calibration of measuring equipment’s is carried out by external authorized agency / company. The equipment’s include:

Tk-Safety Valves, TK-Anti Explosion-Fire Arrester Bypass Safety Systems,pressure gauges, check lock level gauges, Regulator

Equipments:

- Multimeter

- Circuit Tester

- Flow Meters

- Hand Held Gas Detectors

- Gas Leak Test Device

- There are number of fittings mounted on the top of the tank permit safe filling and use

- Each tank should be kept locked

- Each tile should be equipped with at least a magnetic level indicator.

- A fixed maximum level gauge.

- A shut off value for each connection of outlet pipes for both gases and liquid phase.

- A double check valve in the filling connection.

- Gas leak detection system

- Gas tank in all OTS pipe are protected with Gas leak detection system

- Control panel (including sensor) flushing light alarm

- Horn 15% level and closing the gas supply at 30% level 0 to 100% indicator is zone.

Pipe Network Final Testing:

- Nitrogen gas testing for filling line at 30 Bar.

- Nitrogen testing & purging for LPG Tanks

- Penetrate test

- Leak soap test for all joints

- Visual Inspection for all joints

- Nitrogen gas testing for all supply line at 6 Bar.

- These above testing carried out as per the testing standards BS 3636 and BS 5482. Visual Inspection BS 5289 –Any national testing codes may be introduced if required under the national Health & Safety national or international directives.

Final Test

Tank Yard Area

- Gas Tank installation

- Gas tank deluge system functioning

- Gas tank test pressure

- Filling line test pressure

- Earthen of filling line

- Supply line test pressure Detection System Control panel functioning

- Control panel connection

- Detector 12V & 220V functioning

Acceptance Criteria

As per the supplier of the measuring gauges the acceptance criteria should not exceed more than 3%.

Video Presentations

- TechnoKontrol Safety Videos

- What is B.L.E.E.V.E.? Explanation

- Fuel explosion examples

- Fuel Barrel Flame Ignition & Welding Test - Prueba de Ignición y Soldadura en un Barril de Combustible

- Pipeline Explosion Test - Prueba Anti-Explosión en Ductos

- Security Test (SPA) - Prueba de Seguridad

- Heat Conductivity of TK Alloys - Conductividad térmica de malla TK

- Fuel Vaporization Test - Prueba de vaporización de combustible

- Types of TK Alloy Formats - Formatos de presentación de malla TK

- Alloy Vaporization Test

ATEX - European Antiexplosive Safety Directives

PREPARATION/DEGASIFICATION OF A PETROL STATION FUEL TANK, FUEL TANKERS, STORAGE FACILITIES BEFORE ATEX/NFPA: TK-ANTI-EXPLOSION ALLOYS INSTALLATION

ATEX/NFPA SAFETY DIRECTIVES FOR ATMOSPHERIC GAS/PETROL-CHEMICAL RISK-EXPLOSION ZONES

ATEX/NFPA EXTREME DANGER-DISCHARGING OF EXPLOSIVE GASES/VAPOURS AT PETROL STATIONS, MANHOLES, STORAGE TANKS

IMAGE OF AN ATEX/NFPA PETROL STATION MANHOLE REFUELING POINT WITHOUT TECHNOKONTROL ANTI-EXPLOSION ALLOYS

ATEX/NFPA ANTI-EXPLOSION/SAFETY DISCHARGING-REFUELING VALVES FOR PETROL STATIONS, FUEL DEPOTS, REFINERIES, PETRO-CHEMICAL PLANTS

ATEX/NFPA ANTI EXPLOSION, ANTI-ELECTROSTATIC, ANTI-SLOSHING, ANTI-VAPOR SAFETY VALVES "CUSTOM MADE" FOR EACH CLIENT AND TECHNICAL-INSTALLATION REQUIREMENTS

ATEX-/NFPA PETROL STATIONS-MAN HOLES, STORAGE FACILITIES, REFUELING AREAS - ATEX-EU/NFPA EXPLOSIVE ATMOSPHERIC DIRECTIVE DANGER SECTIONS

ATEX-NFPA TECHNOKONTROL ANTI-EXPLOSION-SPECIALIST SAFETY TECHNOLOGIES

SPECIALIST UNIQUE PATENTED ALLOY FORMULATIONS & DESIGNS FOR ALL ENGINEERING-TECHNICAL REQUIREMENTS INCLUDING USAGE FROM PROTECTION-SAFETY TECHNOLOGIES TO PETROL-CHEMICAL-ENVIRONMENTAL INDUSTRIES

TECHNOKONTROL SPECIALIS ANTI-VAPORIZATION, ANTI-THERMAL & ANTI-ELECTROSTATIC CHARGES ALLOYS FORMULATIONS

ANTI-EMPS (ELECTROMAGNETIC PULSES/RADIATION), SPACE/SATELLITE/AVIATION EXTREME THERMAL HEAT ATMOSPHERIC RE-ENTRY ALLOYS, ETC.

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Videos

Security

Pipeline explosion videos

Documentation

- Nigeria Pipleine-Storage Theft/Vandalism Study

- Oil spill and explosion at Shell's Trans Nigeria Pipeline

- Petrol Tanker Disaster, Pipeline Vandalization

- What is "Hot Tapping" a Pipeline or Storage Tank?

- Comportamiento de un gasoducto con fisuras / Behaviour of a cracked gas pipeline

Metal Stress Related Studies in Gas Cyliders, Gas Tanks & Pipelines

- Study on corrosion resistance of gas cylinder materials in HF, HCl and HBr environments

- Evaluation of the effects of natural gas contaminants on corrosions in compressed natural gas storage systems

- Safe use of gas cylinders in marine service

- A case study for crack detection within a gas cylinder using acoustic emission testing

- Effects of water and gas compositions on the internal corrosion of gas pipelines

- Hydrogen cylinders and transport vessels

- Progress in improving cylinder gas purity

- Corrosion resistance of nickel-containing alloys in hydrofluoric acid, hydrogene fluorid and fluorine

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Video explosions

- Gas Cylinder Bottles Transport Truck Explosion

- South Korea Gas Explosion Caught on Street Cam

- City Gas Pipeline Explosion - USA

- Town Centre Natural Gas Pipeline Explosion - UK

- Gas Pipeline Explosion

- Deadly Gas Line Explosion

- Pipeline Huge Blast

- Pipeline City Explosion

- Gas Pipeline Explosion at China

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects