TK-Emergency/Social Housing

TK-Emergency Housing Construction Technologies

TK-Housing Projects® has the answer to all types of accommodation needs through an innovative system of modular prefabricated houses that represents the immediate future in the world of construction.

Thanks to our system we can assure our clients incredibly rapid terms on delivery and huge savings on costs and transport and an amazing timescale from order to a completed house.

Another advantage of our system is that we can build these homes, schools, hospitals with or without basic infrastructres as water, electricity, sewage, roads,etc.

Our buildings are custom made for each client or government and we only wish to produce a long lasting product with a long term quality guarantee which is paramount for Technkontrol´s reputation as a global leader in the safety-security sector.

TK-Housing can adapt to any region, any terrain, to all conditions from building social housing in deserts to military bases in jungles or hospitals in city centres.

When access is difficult our houses can be built successfully and on almost any type of terrain and under any climatic conditions.

Our solid and well insulated modular houses have passed strict building and installation controls which ensure the guarantee of our construction system and we only manufacture in the European Union under full E.U Quality & Safety Standards.

We are always trying to increase our product portfolio and surpass our clients possible needs, thus using materials and designs which are essential to cover all possible present & future requirements from high heat exposure to extreme cold weather and in the worse scenario civil or military unrest regions where our bullet or blast proof safety materials are essential at civilian, industrial or military level.

All these benefits are all complimented by an efficient quality build and extreme building speed as at Technokontrol we know that time is an essential part of any project and many of our clients haven´t the time to wait for a conventional long term build as their possible needs are to have “a roof over their heads” and not having the luxury to wait for months or years for a conventional home.

When access is difficult our houses can be built successfully and on almost any type of terrain.

Our solid and well insulated modular houses have passed strict building and installation controls which ensure the guarantee of our construction system.

Characteristics

Building and installation time

- Fast construction

- Process total of 6 hours

- No need for highly skilled builders

- Each component is easy to locate and identify

Security

- Tested against wind and earth tremors

- Designs can be altered in height and roof angle to adapt to different locations and various climates. (Strong wind, rain, snow and extreme heat or cold)

Long-lasting

- Reinforced steel structure

- Quality materials

- Exterior made with reinforced, galvanised steel laminates with superior insulation

- External finishes super resistant to extreme weather conditions

Low cost

- Prefabricated houses with low cost advantage

- High quality, low cost materials fabricated industrially

- Competitive logistical prices

- Easy to transport and store

Transportable and reinstallable

- The modular design of our constructions makes them easy to transport

- Possibility to remove and relocate the construction after completion

- Another outstanding characteristic of our houses is the super easy storage. The flat pack occupies a space of only 4 x 0.8 metres

- The modules can be stored and built rapidly, should the need arise

Quality

- Walls and roof with super quality insulation

- Preinstalled electric wiring system

- Plugs and switches preinstalled to a main fuse box

- Installation of kitchen and bathroom fittings

- Superior insulation provided by conventional materials. Independent laboratories tests have demonstrated the thermal and acoustic quality in our houses have obtained a higher level than conventional dwellings

Environmentaly friendly

- Zero impact on the environment

- Suitable for any type of terrain

- Designed following environmental codes

- Possibility to make from completely renewable materials

Guarantee

- Guarantee direct from Technokontrol on construction and installation

Construction System

- Innovative system

- Basic modular can be extended and adapted

- Strength of construction

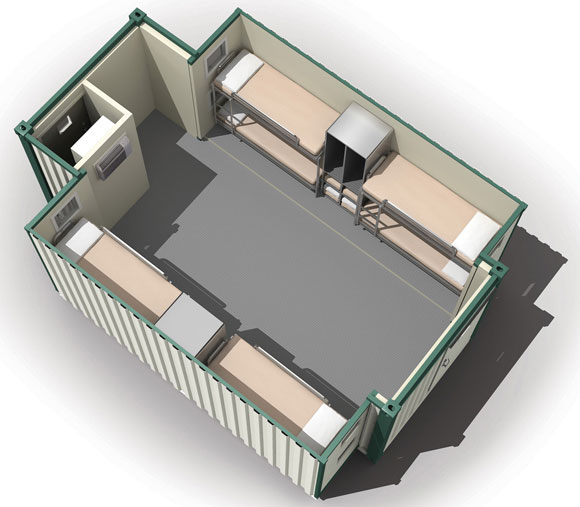

Our prefabricated modules of 20 m2 (2.80 m maximum height and 2.28 m minimum height) are ready to use or to be used as a base to extend and adapt.

The majority of the outside surface of the house is metallic. Each module is made up of different folding structures that pivot and allow the structure to be flat packed and ready for transport. Once opened on site, they form a solid, stable habitat that is then anchored into position.

Extending and Amplifying Options

Another super advantage of our houses is the savings that can be made when choosing to amplify the modular.

The houses are designed in individual modules that are guaranteed safe and stable no matter what the weather conditions.

As the family grows and more space is needed the solution is as simple as adding another modular and joining it to the original in the best position available. Depending on the needs of the family, the new annex might have to be accessible to the previous one and would require a skilled tradesman to complete this.

Installation of modern technologies such as the Internet, telephone and demotic systems etc., are simple and easy to install in our houses because they are designed with easy access wiring conducts. All the rooms are joined to a narrow central hall where cables can be installed and passed into rooms without spoiling the finish of the house.

Building and Installation

1. Unpacking the Module

To reduce the transport costs, more than one unit can be delivered in each container. We can deliver of up to four units at a time, depending on the overall square metres of each unit ordered.

To unload the container, a crane/fork lift truck is needed using a chain to lift from the container and lower it onto the base where the module is to be built. Once the modules have been removed from the container they are easy to manage with a fork lift truck.

2. Locating

The first fitting phase is to fix the central part of the module to the base. The forklift should position the structure without unfolding any of the panels over the pre-drilled holes in the concrete base.

Once in place, the steel anchors that are provided can be introduced and washers are fitted and bolted into place. This completes the first central part of the build

3. Unfolding

The two roof panels can then be unfolded and lifted, the underside of which are the walls, there are rings that have to be located and pulled to allow the wall to be separated from the roof. The roof will continue to be movable until the walls are pushed out from under it.

The roof can then be provisionally held up by the walls until the lateral walls are unfolded and joined to make corners.

Next is to unfold and fit all the remaining parts that are required to finish the exterior and unfold and fit the internal walls.

4. Weather proofing and sealing

Once all the panels have been fitted into place we can begin sealing the joints with the rubber that is provided with the module and finished with silicone in places where there is a possibility of water entering.

Similar to the exterior, the interior has rubber moulds that are fitted into corners. The metal edges in the Cen- tre of the house are also covered with rubber and sealed with silicone to avoid humidity and draughts entering the module.

Versatile spaces

We have lots of solutions for every need possible in prefabricated housing. We can provide our clients with modules of 20, 35, 40, 55, 60, 75 even up to 200 m2.

We can build any type of building from homes, company housing, military bases, schools, hospitals, offices, etc.

Images and specifications are for illustration purposes and may have to be altered for technical reasons

Quality materials

The design of our houses has been made adhering to all international regulations

TK Foundations

The dwelling can be constructed on stilts set in concrete or built on a ready-made concrete foundation depending on the type of land and the clients’ preferences.

TK External Walls

The external panels consist of two pre-painted steel laminates ST-37 with a thickness of 0.5/0.6 mm. Between the panels is polyuretane expanding foam with a density of 40 kg per m2, making the total external wall thickness 50 mm. The external finsh the depends on th clients’ wishes. Internal walls are made of the same materials as the external and have a thickness of 30 mm.

TK Roof

Overlapping panels (which have previously been described) with a minimum thickness of 40 mm. The exterior side can be ordered in various types of finishes.

TK Heating

The materials used in our houses make them super insulated, warm and comfortable; however they are still designed to allow the installation of gas, electric, solar and other sources of heat. Optional Hot-Cold air conditioning units can be installed. Solar panel hot water and heating systems available.

TK Windows

The windows are ready lacquered in a white finish and open on side sliding runners. We can also offer double glazing, tinted glass, bullets proof or any other additional requirements.

TK Electric

The electrics are fitted in agreement with the electro technical code of low tension and complying with the rules of the supplying company. The system consists of various lines for sources of light and power. The general supply source is based in the entrance to the dwelling. The sockets and interrupters are high quality and match the colour of the interior walls. All the electric installations are designed to be hidden inside the internal walls.

Optional services as fire/smoke/gas /security alarm systems can be incorporated. Cold-Hot Air conditioning units can be installed in all rooms. Dust/sand filtering systems can be also incorporated.

TK Plumbing and Sanitation

The pipes and tubes are made from flexible PVC with different colours for different uses with quick fit PVC joints. The sanitation pipe is (110 mm, 50 mm and 40 mm) depending on the drainage system and goes directly into the wall. The PVC is joined with rubber to avoid leaks, humidity and odour.

Waste and clean water systems can be attached to the home in the event of non- connected sewage and water system available. These can be means of large clean filtered water tanks and underground sewage tanks which can maintained easily.

TK Doors

The doors are a bloc type. The interior doors are solid panels with a honeycomb centre and finished with prefabricated smooth sheet metal. Can be personalized to the customers requirements. Other specialist doors can be ordered which are for extreme weather.

TK Kitchens

The kitchen includes cupboards and storage below and above the stainless steel sink and taps that are prepared with a quick fit system that does not require skilled tradesmen. All additional kitchen appliances can be also incorporated as gas/electric cooker, stove, oven, microwave, fridge, freezer, washing machine, dryer, kitchen extraction system, gas/fire alarm ,etc.

Optional products

1. TK Solar Panels

Hot water and electricity

Technokontrol can offer our clients many options and one of these is to install on the house roof a solar water heating system which will allow to have hot water for showers and for cooking. There is the possibility to incorporate an under floor water heating system or internal hot water radiators. (cold climatic regions). We can also install a combined water-energy solar panel system which will allow the home to have enough electricity to light the led lighting systems, air conditioning units and kitchen appliances. These options can be requested by the client and we can custom make each order depending on the projects climatic, technological and logistical needs.

2. TK Gas cylinders

Cylinders and bottles

Technokontrol has a varied portfolio of anti-explosion safety gas tanks/cylinders. We can install our anti-explosion gas cylinder heating/cooking gas bottle/cylinder in any home. These gas bottles/cylinders can be from the small 5 litre to the 26 litre units. In the event of having GNV (Autogas) our bottles can also be reconnected to be used as an alternative or even our TK-Alloy can be installed in the Autogas gas cylinders to protect against explosion, sabotage or terrorist attacks.

3. TK Wall systems

Fire / Heat / Blast / Bullet proof

Technokontrol installs excellent quality materials and wall products. Many of our clients have specialist needs from a special double wall for heat or fire protection to the need to have bullet & blast proof walls and safety systems. Our TK-Blast technology can be installed as an optional package to protect the assets and employees / clients against terrorrist-sabotage attacks. Our Heat-wall panels can also reach and protect direct heat/fire blast for up to 3 hours at 1600º which is very important to have in petro-chemical installations due to the possible explosion or fire exposure in the event of an accident or direct sabotage or terrorist attack.

4. TK Safety alarms

Fire / Gas / Smoke

At Technokontrol safety is paramount and we can offer our clients the benefits of using our exclusive gas/fire/smoke/safety alarms which can shut off gas automatically or detect smoke, fumes, unauthorized entries, etc which by means of a sounding and visual aide will indicate this situation to the client. Direct mobile connection for virtual live internet o mobile vision of the home when not present is also possible which will be connected to these above mentioned safety aides to make the home the most secure possible

Optional services

Technokontrol has a large portfolio of products and services which depending on the product and its use in many occasions it can be directly purchased through our retail division ready for use as for example our TK-Anti Explosion Safety Fuel Cans and in other products as the TK-Anti Explosion Alloys for Home/DIY/Private/Motorsport. These simple products do not require high levels of technical backup or knowledge for its use or application, even though we at Technokontrol are available for our clients needs to advise in the event of any possible issues with regards to our products or their application.

"Safety is paramount and any question is better answered than a mistake occurring for not asking". On the other hand many other of our products and services due to their industrial and specialist application are complex and require high levels of technological knowledge with regards of the manufacturing and of their application and installation.

TK Security Services

TK Global Logistical Services

TK Global Maintenance Services

TK Global Servicing Services

TK Medical & Hospital Services

TK Emergency Medi-Air Services

We at Technokontrol believe that an essential part of the Technokontrol experience is the “Key in Hand” option and we strive to give our client’s the option of a 100% hassle free experience anywhere in the world. If our client requires us to travel to supervise, verify and to apply any of our products or services from a motor yacht in the Caribbean, to a private plane in the USA or to a Speed boat in the UAE we will be available on hand at an obvious extra cost. Due to the availability of global communications the TK-Engineering Team can via conference call, telephone or other possible means of communication offer advice minute by minute and even view if possible the correct installation or answer in-situ with any queries without travelling and without any additional expense to the client other than the purchase of the respective product.

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Images

Click on an image to enlarge

Current Projects

Eye of Osiris

Eye of Osiris National Security Food Production Plant

Ojo de Osiris

Ojo de Pachamama

TK Refinery (Spanish)

TK Refinery (English)

TK RF5000 Generator (Spanish)

TK Emergency/Social Housing (English)

TK Housing (Spanish)

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

TK-Global Engineering - Where efficiency and reliability become a reality