TK-AXAVFT Anti-Explosion Aviation Fuel Tanks

TechnoKontrol on Aviation

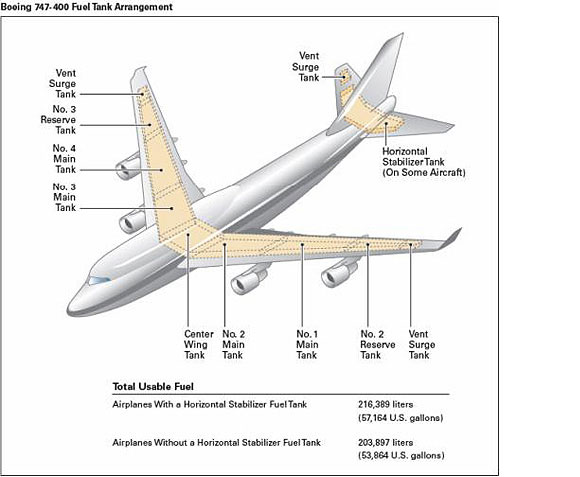

In an industry where there are more and more accidents (since 1960 there have been over 18 aeroplanes which have been damaged or destroyed due to a fuel tank explosion – FAA statement in report regarding explosions) occurring every year, we at TechnoKontrol believe that it is vital that we keep working so as to improve the quality of the products used within the Aviation Industry.

Although we are constantly working so as to bring new products to the market place, at present we can provide the following products;

- We are currently producing a special materias based on metal alloys (for both smaller and larger planes alike) which can be installed within the planes fuel tank and will be both explosion and fire proof.

- A cheaper, thinner and lighter explosion proof textile, mesh material in which studies have proven that we can significantly reduce an aeroplanes annual running costs due to weigh reduction compared to other used products as foams plastics for anti-fire, safety features, etc.

- Once deposited within the airplanes fuel tank, TechnoKontrol can ensure that our products can take away any threat of an explosion occurring.

- TechnoKontrol Valves which can reduce delivery times (unloading times) of the jet fuel from the tanker to the plane by as much as 50%.

- As with all of our products, we will offer a 10 year guarantee and mnaintennce programms.

- Also all of our products are transferable, hence, they can be used time and time again within either the same vehicle or different vehicles.

- As TechnoKontrol are working with many of the largest insurance companies in the world, we are confident that we can reduce your insurance premium by as much as 30%.

TechnoKontrol Aerospace Research & Development

TechnoKontrol Aerospace

TechnoKontrol Aerospace designed products are currently undergoing testing for both FAA and EASA approval and via using a computer flight simulator; our products have already been proven to save up to 90,000USD (using a 60 seat passenger plane and working off fuel prices based on April 2011) in fuel. Thus we are confident that within the very near future, we will be able to supply our clients with a lighter product which provides not only a greater fire resistance than current industry standards but also a product which will offer additional acoustic benefits. Obviously this not only means that the aircraft will save on fuel costs but it will also allow the aircraft to have a greater autonomy; carry more passengers/cargo but also will allow the operator to reduce fuel contamination into the atmosphere. As the above tests were taken within a 60 seat passenger plane simulator, one can only imagine what the fuel cost reduction would be within an Airbus 380.

TechnoKontrol Aircraft Applications

TecnoKontrol not only delivers the above mentioned security and greater efficiency benefits but we can also offer our clients much great stability benefits. Our mesh or ball format (which can be easily installed within any fuel tank at its servicing period) will bring with it an extra benefit of "slosh" reduction. Any pilot knows that within smaller aircrafts the fuel "slosh" movement is an important issue especially in bad weather where onboard flight computers are not in place so as to re-balance the aircraft. Thus having our specially designed TechoKontrol mesh within the fuel tank will allow the pilot to enjoy a much more stable flight and will ensure that their turns; landings and stress sections are all made much easier.

TechnoKontrol Airship R&D Technology

As part of our R&D programme; TechnoKontrol has been working within the airship industry. We have been involved in assisting the use of our technology so as to not only protect the new airships external skin (as this was one of the major flaws in the past) and fuel tank protection but also to design a new ballast system where the main issue with regards of stability is paramount. The main focal point at present within the Airship industry is to be able to re-balance the airship with different cargo sizes and weights so as to increase its payload and flight stability-security.

Video section

Please refer to our videos where one can see that refuelling of a light-aircraft with fuel on fire will not cause an explosion or fire. Testing with jet engine fuel tanks has begun and will allow us to increase our technology for the global aeronautical-aerospace industries.

TechnoKontrol provides great turn stability

The videos located on the top right hand side of this page will show what normally happens to aviation vehicles that do not use our TechnoKontrol Product inside when a fire or explosion takes place and we at TechnoKontrol will be happy to demonstrate to any potential client how we can, through the use of our product, help to prevent these accidents from ever occurring again.

Techno Kontrol Alloy Safety Products

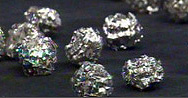

TechnoKontrol Alloy Safety products are a unique non-combustible material consisting of a specially designed metal alloy mesh mechanically produced via a patented three dimensional production system.

TechnoKontrol Safety Technology Alloys, panels and safety technology systems are comprised of patented alloy material manufactured in a three dimensional manner mechanically produced into a mesh, ball or textile format to form a unique non-combustible material that is Fire, Blast, Moisture, Corrosion, heat, sound and electromagnetic wave resistant depending for its final usage.In the case of blast, fire, heat or explosions TechnoKontrol Safety Technology Systems will perform as no other product in the market, especially, in the oil-gas-chemical industries.

As mentioned above, the TechnoKontrol Safety Technology Alloy stops the explosion of any tank filled with gasoline, diesel, gas, petroleum or any other type of flammable, gaseous or liquid substance.

In addition our TechnoKontrol Alloy only consumes(volume) a minimum 1% of the overall tanks capacity when using the net and 1.5% when using the balls. Therefore, if a 100 litres tank is filled with our alloy net, the tank has a capacity of 99 litres, and if filled with the balls, it has a capacity of 98.5 litres. Thus our TechnoKontrol Safety Alloy completely avoids the oxidation within the interior part of the tank,(if tank is new or stops increasing oxidation if already an used tank) and in turn stops explosions 100% of the time.

TK Alloy Main Benefits:

- Anti-Explosive

- Anti-B.L.E.V.E.

- Anti-Slosh.

- Anti-Oxidation

- Reduces vaporization of fuels

- Light weight

- Easy to apply & use.

- Eco-Friendly & 100% recycable.

- Long product life.

- Used with any types of fuels and Home-DIY chemicals(Gasolines,Kerosene,Alcohols,cleaning chemicals,etc)

- No maintenance(minimun supervision if required).

- Manufactured under full EU Quality & Safety Standards and guidelines.

Other benefits of TechnoKontrol are;

- Techno-Kontrol Alloy stabilises the liquid in moving tanks(such as Ships or Transport Trucks) and in doing so, helps to stop any damage to the interior part of the tank. This product is currently being used within high speed navy boats among other vehicles.(FIM-World International Motorbike Federation-obligatory),(WPPA-World Profesional Power Boat Association),etc.

- Techno-Kontrol Alloy is completely compatible with all types of combustibles and does not need to change/alter any of its chemical properties to do so.

- Techno-Kontrol Alloys cancels out electrostatic charges.

Technokontrol TK-Alloy Safety Products can be purchased in either ball or mesh format, however, for easy application we recommend the use of TK-Ball format as its much easier, quicker and applicable then the TK-Mesh format. The TK-Ball format can be introduced into any fuel can, fuel powered motor engine fuel deposit (motorbikes, motorboats, light aircraft, grass cutters, leaves blower, tree cutters, etc...), by hand. (Please refer & study all Health & Safety instructions before use).

| TK-BALL FORMAT (15 LITRES) | K15B (Please refer to catalogue). |

| TK-BALL FORMAT (35 LITRES) | TK35B (Please refer to catalogue). |

| TK-MESH FORMAT(25 LITRES) | TK25M (Please refer to catalogue). |

| TK-MESH FORMAT(50 LITRES) | TK50M (Please refer to catalogue). |

| TK-SAFETY ALLOY SPECIAL | Can be purchased in larger amounts and packaged up to 1000 litres boxes for airfreight or courier delivery |

Technokontrol Safety Technology Alloy is lightweight, flexible and recyclable.

Although it has many uses, some of the more commonly used are;

- The alloy mesh can be used in the construction of fire and blast resistant barriers

- Pipelines and gas/oil industries

- Military installations

- Airline Industry

- Fuel based enclosures

- Fuel cans & tankers

- Engineering

- Gardening & D.I.Y.

- Cable tray & security vaults enclosures

- High voltage electrical equipment enclosures

- Oil and Gas pipe enclosures

- Ductwork Fume hood exhaust Petrol stations Valve actuator enclosures Fan enclosures

- Compressor tankers

- Fuel pipelines & deposits

- Dust collector

- Chemical storage.

- Gas bottle prodcution & storage .

- Heat shield filling areas.

- Blast enclosures

- Spray Booths

- Storage Vaults, Stairwell and Escalator enclosures

- Transformer

Our TechnoKontrol Alloy TK-Ball & TK-Mesh is exceptionally flexible, resistant to heat and once installed requires very little maintenance even within the most aggressive of atmospheres.

As per our Mission Statement, at Techno Kontrol we are constantly reinvesting into our Research; Development and Investigation departments so as to be able to adapt our patented alloy and manufacturing systems in order to continually expand our product lines. The following are just three examples of where you can find our specially designed products today;

- Gas Bottles

- Fire prevention within Wall Panelling, Boards and Duct Systems

- Revolutionary clothing applications which are currently being tested within Fire Fighters Helmets, Gloves and other Equipment.

In the case of fire prevention and explosions please read the Physical and Chemical Characteristics of Techno Kontrol which can be found within the How Techno Kontrol Works Section.

Techno Kontrol International Safety & Quality Standards

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards which in many cases we surpass present regulations.

- US NFPA-69-2008-Standards on Explosion preventing Systems

- UK- SI 1982/630- Petroleum Spirit for use in motor vechicles & keeping in plastic containers.

- EU- ADR Directive 1999/36-CE

- ISO 9000-ISO14000-ISO18000-1SO23000(2012)

- CE Certified Manufacturer.(2012)

Technokontrol Safety Technology Products and Systems are used, recommended or obligatory in many sectors:

- Government Fire & Accident Authorites.

- Uk Health & Safety Authorities.

- Petroleum Industry.

- International Motor Racing.

- International Power Boat Racing.

TechnoKontrol Aviation

- Eagle Eye II Amphibious Low Level Ground Flight & Water Base Landings

- TK Eagle Eye III & IV

- TK Aviation Civil Use

- TK Aviation Law Enforcement

- Refueling on fire

- Landing the Eagle Eye Aircraft without undercarriage down.(No wheels down)

- Jet Engines Video

- Liquids balance

- Technical video

- Fuel Barrel Flame Ignition & Welding Test - Prueba de Ignición y Soldadura en un Barril de Combustible

- Aircraft Fire Fuel Tank Test - Prueba de ignición en tanque de combustible de un aeroplano

- TK Outdoor Tests Presentation - Fire Services / KNPC Kuwait

- Security Test (SPA) - Prueba de Seguridad

- Heat Conductivity of TK Alloys - Conductividad térmica de malla TK

- Types of TK Alloy Formats - Formatos de presentación de malla TK

Aviation & Airports Protection

Videos

TK Safety Technology

Industries

- Petroleum Industry

- Construction Industry

- Transportation & Auto Industry

- Aviation

- Maritime

- Military & Security

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

TK-Global Engineering - Where efficiency and reliability become a reality

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board