TK-GCMR Gas Condensate Refinery to Diesel-Kerosene-LPG-Gasoline

Application and allocation of Gas Condensate TechnoKontrol Refinery (TK-GCMR)

Gas condensate is a typical by-product of both, gas- and oil production. In the gas field it is generated in the gas drying process. In the oil field it forms a part of the associated gas and such is mostly flared.

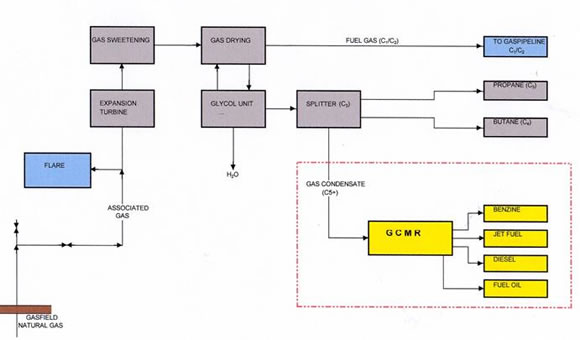

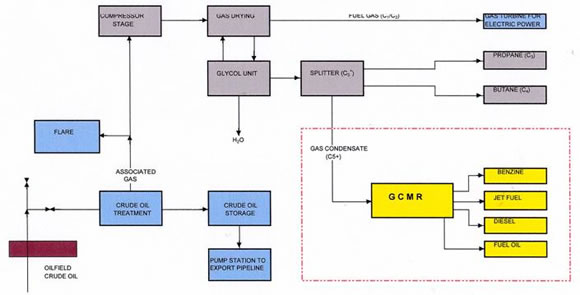

Instead of being flared, gas condensate could be used to produce valuable refinery products by feeding them to TK-GCMR. The attached block diagrams demonstrate how TK-GCMR could typically be integrated into gas field facilities (ATT01) or oil field facilities (ATT02).

Features of the TK-GCMR

TK-GCMR is a refinery supplied in pre-erected and pre-tested packages and designed to process 25.000 BPD of gas condensate per single stream.

It is designed to optimise the output of mainly gasoline, jet fuel, diesel and fuel oil in high quality. The design is based on industrially proven technology and is in accordance with internationally accepted rules, codes and standard as well as European environmental regulations.

TK-GCMR is equipped with modern and up-to-date integrated refinery information system for monitoring & control of process and performance of the plant.

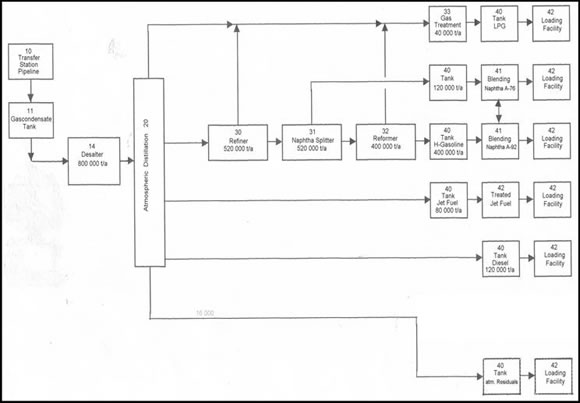

TK-GCMR is a rather comprehensive refinery which therefore includes various process units like atmospheric distillation, refiner and reformer. (Therefore, it is important to distinguish the skid-mounted TK-GCMR from e.g. simple topping plants which typically run on crude oil are often skid-mounted and called mini refineries too).

The scope of the TK-GCMR includes besides the process units also off-sites and utilities according to requirements on site. However, TK-GCMR could be designed as almost self-sufficient with regard to utilities requiring water as only imported utility.

The TK-GCMR is offered on a LSTK basis or “Keys in hands” option. This means, that the required EPC work (engineering, procurement and construction) will be realised by a general contractor with single responsibility towards the client or a full package as required by the client.

Key Arguments for TK-GCMR

The key arguments for the TK-GCMR concept are as follows:

(1) Its high level of self-sufficiency makes TK-GCMR an almost independent source of gasoline, jet fuel, diesel, fuel oil and even electricity for small, remote and under-developed markets or oil- and gasproduction fields.

(2) The pre-assembled and pre-tested modules of the TK-GCMR result in short transport, erection and commissioning times and eventually smaller related cost compared to conventional refineries.

(3) Due to modularised package concept, TK-GCMR could be easily removed to alternative product markets or feedstock sources, if need be. For the same reason it is also easy in operation and very well suited as pilot plant for testing and/or training purposes.

(4) The integrated refinery information system helps to optimise operational efficiency of the plant and to maximise the business margin.

(5) Because of the favourable feedstock – gas condensate instead of crude oil –TK- GCMR provides cost-effective high quality products which exceed European as well as US-American quality standards. This and the fact that 100% of the feed is converted into products results in a considerably shorter pay-back period than comparable crude oil refinery projects of similar product output.

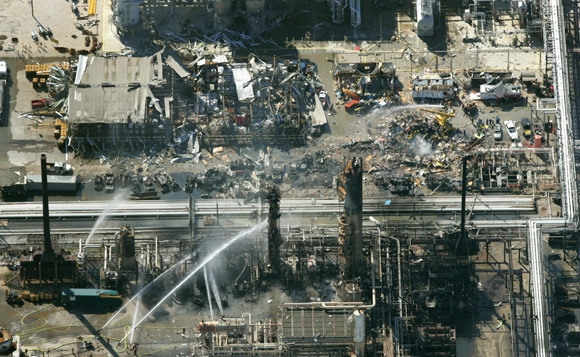

(6) Technokontrol exclusive safety technology will allow the refinery to benefit from a anti-explosive, anti-bleve technology by introducing in all of the possible areas our technology to prevent any types of accidents, especially,gas explosions,fires,bleves,sabotage,etc.

(7) We also strive to reduce all possible contamination by using our exclusive TK-Chimney Contamination Filtering Technology.

(8) Technokontrol products and safety technology surpasses many International safety requirements including the guidelines of the US NFPA-United States National Fire & Prevention Association guidelines regarding the prevention of Explosions US NFPA-69-2008 Guidelines.

(9) Technokontrol manufactures its safety products in the EU under full CE safety requirements and follows full quality & safety guidelines from internationally recognized auditors as the ISO Organization.

(10) Technokontrol prides itself in having quality certificates as the IS09000-ISO14000-ISO18000-ISO23000 and is a member of the US NFPA.

(11) Technokontrol Safety Technology is used ,recommended or obligatory from the UK Health & Safety Authorites, the Australian Fire Authorities, The International MotorBike Racing Authority(FIM), to the World Professional Powerboat Association.(WPPA),etc.

The Process and the TK Plant

Capacity of the Plant

The refinery is designed for an annual capacity of

- Max. 937.500 t/a = 25.000 BPD Gascondensate

- The operation time of the refinery is 8.000 hours per year.

Following our process technology per example the following endproducts can be achieved. The exact endproducts depend on the real gas analysis.

| Gas consensate |

LPG t/y |

Benzine t/y |

Kerosene t/y |

Diesel t/y |

Fuel Oil t/y |

| 100 % | 28.125 | 487.500 | 121.875 | 225.000 | 62.500 |

t/y = tons per year

The above figures are based on a throughput of 937.500 t/y respective

25.000 BPD.

Additionally 7.500 tons/year (7.500.000 m³/year) of gas are produced, which will be used for the own energy supply and therefore is no need to use additional gas from outside.

The plant is following international standards. The plant can go in operation after signing of contract and clarification of all technical and commercial points in less than 2 years.

Main Equipment

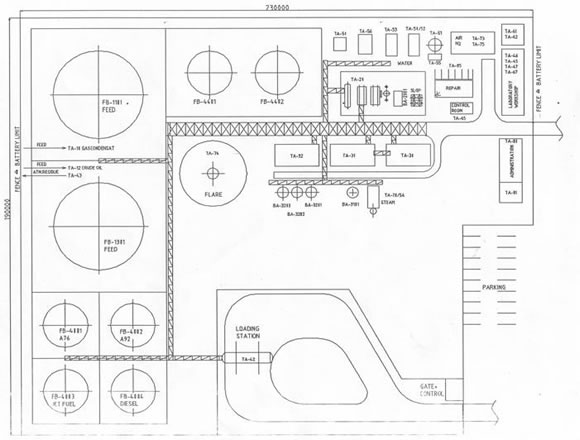

The plant is supplied with all required units and the so-called off-sites, so it can go on stream with this equipment. A Lay-out of the plant is attached. The required area for the plant is around 43.000m².

The equipment is as follows:

- TK-tankfarm for the gascondensate (reserve for 7 days)

- The desalination unit

- The atmospheric distillation

- The disulphurisation of benzine

- The benzine splitter

- The reformer unit

- TK-tankfarm for endproducts (reserve for 3 days)

- TK-Safety Technology

Off-sites

- Water processing plant

- Steam producing unit

- Control- and pressure air

- Slope system

- Flare unit

- Electr.power supply

- TK-tankfarm for intermediate products (reserve 3 days)

- Repair workshops

- Spare parts package

- Piping and instrumentation

- Laboratory

- Process control room

- Administration and personnel’s dayroom

- Fire fighting equipment

- TK-Safety Technology

Installation and Putting in Operation

The units are supplied skid mounted and in part units. Therefore the total installation time will only be 4-8 months, depending on local conditions.

Putting in Operation takes place in two steps:

- First will be training of personnel and dry run

- The second step will be going on stream.

The Process Control Room will be supplied in containers, full functioning, so the training of the operation personnel can already start parallel to the installation. The Putting in Operation therefore will be only 3 months.

Products produced and Quality

| Benzene | Normal benzene | A-76 |

| Super benzene | A-93 |

| Kerosene | Sulphur content | <0,2% (Mass.) |

| H2S- content | not tracable | |

| Free water | no | |

| Spec. Gravity (20°C) | <820 kg/m³ | |

| Ignition point | > 40°C | |

| Poor point | < -35°C | |

| Cloud point | < -25°C | |

| Mech. impurities | none |

| Diesel | ||

| Gen.charakter. | Sulphur content | <0,2 % (Mass.) |

| H2S-content | not evident | |

| Free water | none | |

| Mech. Impurities | none | |

| Foll. ASTM-D86 | 95% of boil.analysis | < 340° C |

| Marketing char. | Summer diesel | Winter diesel |

| Density (20°C) | < 850 kg/m³ | < 840 kg/m³ |

| Ignition point | < 40°C | < 40° C |

| Poor point | < -10°C | < -35°C |

| Cloud point | < -5°C | < -25°C |

This quality datas are experienced values which can be slightly changed by the feed characteristic of the gascondensate.

Plant Description

Process Diagram / Refiner – Reformer

Lay Out

Emissions and Effluents

Waste Water

The waste water will be treated in the waste water treatment. This are 3 (three) basins made from concrete. After the basins the water will be fed into a draining basin.

The content in the water is:

- Oil < 10 mg/l

- Salt < 10 ppm

- Sludge from the basins cleaning 1 x / year.

Flue Gas

The process furnaces are fired with refinery waste gas. The burners are designed this way, that the emission levels as listed hereunder will be achieved.

| g/m³ flue gas | |

| CO content | < 170 |

| NOx | < 250 |

| SO2 content | < 200 |

| Dust | < 50 |

View of a TK-GCMR

TK Refinery Consulting Services

Design, fabrication and installation of the plant

Putting in operation, test run, training of local personnel and support of operation for a certain period.

Based on a concluded supply contract a first class german general contractor will, based on the process of TK- CONSULTING, design, fabricate, purchase, deliver and install the plant on the site of the client, turn-key ready for operation.

Within this supply contract a supervision team will take over training of local personnel, putting in operation of the plant and will help operation of the plant for a period to be agreed.

Gas Condensate Technokontrol Refinery

- Open Gas Condensate Technokontrol Refinery (TK-CGRM). (English)

- Abrir Technokontrol Refinería Estratégica Móvil (TK-CGRM). (Spanish)

TK-GCMR can be installed with energy self-sufficiency

Technokontrol Certificates & Associations

Technokontrol Manufactures, Designs & Researches our safety products in the European Union at the highest possible International Accident,Health & Safety standards.

TechnoKontrol is a member of the NFPA

TechnoKontrol Products are ATEX Compliant

(European Antiexplosive Safety Directives)

Technokontrol's Products & Services are insured by

Certificates

Información disponible en español.

Products

What is B.L.E.V.E. explosion?

TechnoKontrol Wikipedia

TechnoKontrol: 1st in Spain for own Technology patents 2013 & 2014

- Ministerio de Industria Turismo y Comercio-OEPM

Technokontrol, the number 1 corporation in Spain filing for its own technology patents, trademarks and utility patents (SPA) - OEPM 2013 The year in numbers (SPA)

TechnoKontrol has been fully verified and certified by Bureau Veritas

Certificates

- ISO 9001 - ES108784-1

- ISO 14001 - ES108782-1

- ISO 45001 - ES108783-1

- ISO 4126

- ISO 28000

- ISO 37000

NFPA-National Fire Protection Association

NFPA-Asociación Nacional de Protección contra el fuego

TechnoKontrol is a member of the NFPA

NFPA 69: Standard on Explosion Prevention Systems, 2016 Edition

Prevent deflagration explosions due to combustible dust particles, gases or vapors with NFPA 69. Combustible dust, gases and vapors produced in industrial settings can pose a significant safety hazard.NFPA 69: Standard on Explosion Prevention Systems offers definitive guidance on explosion protection and prevention systems.

ATEX - European Antiexplosive Safety Directives

- ATEX Guide: Protection in explosive atmospheres

- ATEX-EU/HAZLOZ-USA/NFPA-USA/DSEAR-UK/Explosion Directives TechnoKontrol Additional Anti-Explosion Data

- ATEX Directive in EU Directives

Dangerous Substances and Explosive Atmospheres Regulations - United Kingdom/ATEX

United Nations Economic Commission for Europe - UNECE - TechnoKontrol

- TechnoKontrol information for the UNECE BLEVE working group

Proposal transmitted by the governments of Spain and France

The European Parliament and The Council

Technokontrol's Products & Services are insured by

Dossiers TK Group of Companies

TK-Global Engineering - Where efficiency and reliability become a reality

BP World Report

Static Electricity Dangers and Protection

- Static Electric Discharge Hazard On Bulk Oil Tank Vessels

- Static Electricity - ISGINTT

- Dangers of static electricity and protection in aviation

- Static Electricity - IAPA

- U.S. Chemical Safety and Hazard Investigation Board

US Department of Transport

USA Chemical Safety Board

An independent federal agency investigating chemical accidents to protect workers, the public, and the environment.

About the CSB

CSB Safety Videos

- Chevron Richmond Refinery Explosion

- Deadly Contact

- West, Texas Real Live Blast Damage Video

- Hot Work - Dupont Explosion

- Static Sparks Explosion in Kansas

- Danger of Flammable Gas Accumulation

Articles

- Energy Sector Vulnerabilities: Petroleum (Spanish)

How does fuel exploration drilling, refinering work?

- Petroleum refining basics

- Basic introduction to petrochemicals

- Oil refinery demonstrative

- Process safety management training

Petrol Video Explosions

Video explosions

- Saudi Arabia Fuel Tanker Explosion

- Fuel Tanker Explosion Aftermath

- Mexico Truck Gas Tanker Explosion

- LP Gas Storage Station

- LP Gas Facility

- China Fuel Tanker Motorway Explosion

- PDVSA Refinery Explosion

- City Block Gas Explosion - South Korea

- Chemical Road Tanker Explosion Motorway

- Fuel Tanker Explosion Saudi Arabia

Safety Products System

Safety Products System Eco-Energy Power Plants

Eco-Energy Power Plants TK Aviation

TK Aviation Environmental Industries

Environmental Industries Mining

Mining Petroleum Industry

Petroleum Industry Industrial Projects

Industrial Projects Maritime Industry

Maritime Industry Military Vehicles

Military Vehicles Transportation & Auto

Transportation & Auto Construction Industry

Construction Industry Global Food Industry

Global Food Industry Electronic Safety Systems

Electronic Safety Systems Housing Projects

Housing Projects